RTP equipment for compound semiconductors、SlC、LED and MEMS

Industry applications

Oxide, nitride growth

Ohmic contact rapid alloy

Annealing of silicide alloy

Oxidation reflux

Gallium arsenide process

Other rapid heat treatment processes

Feature:

Infrared halogen lamp tube heating, cooling using air cooling;

PlD temperature control for lamp power, which can accurately control temperature rise, ensuring good reproducibility and temperature uniformity;

The inlet of the material is set on the WAFER surface to avoid cold point production during the annealing process and ensure good temperature uniformity of the product;

Both atmospheric and vacuum treatment methods can be selected, with pre-treatment and purification of the body;

Two sets of process gases are standard and can be expanded to up to 6 sets of process gases;

The maximum size of a measurable single crystal silicon sample is 12inches(300x300MM);

The three safety measures of safe temperature opening protection, temperature controller opening permission protection, and equipment emergency stop safety protection are fully implemented to ensure the safety of the instrument;

Test report:

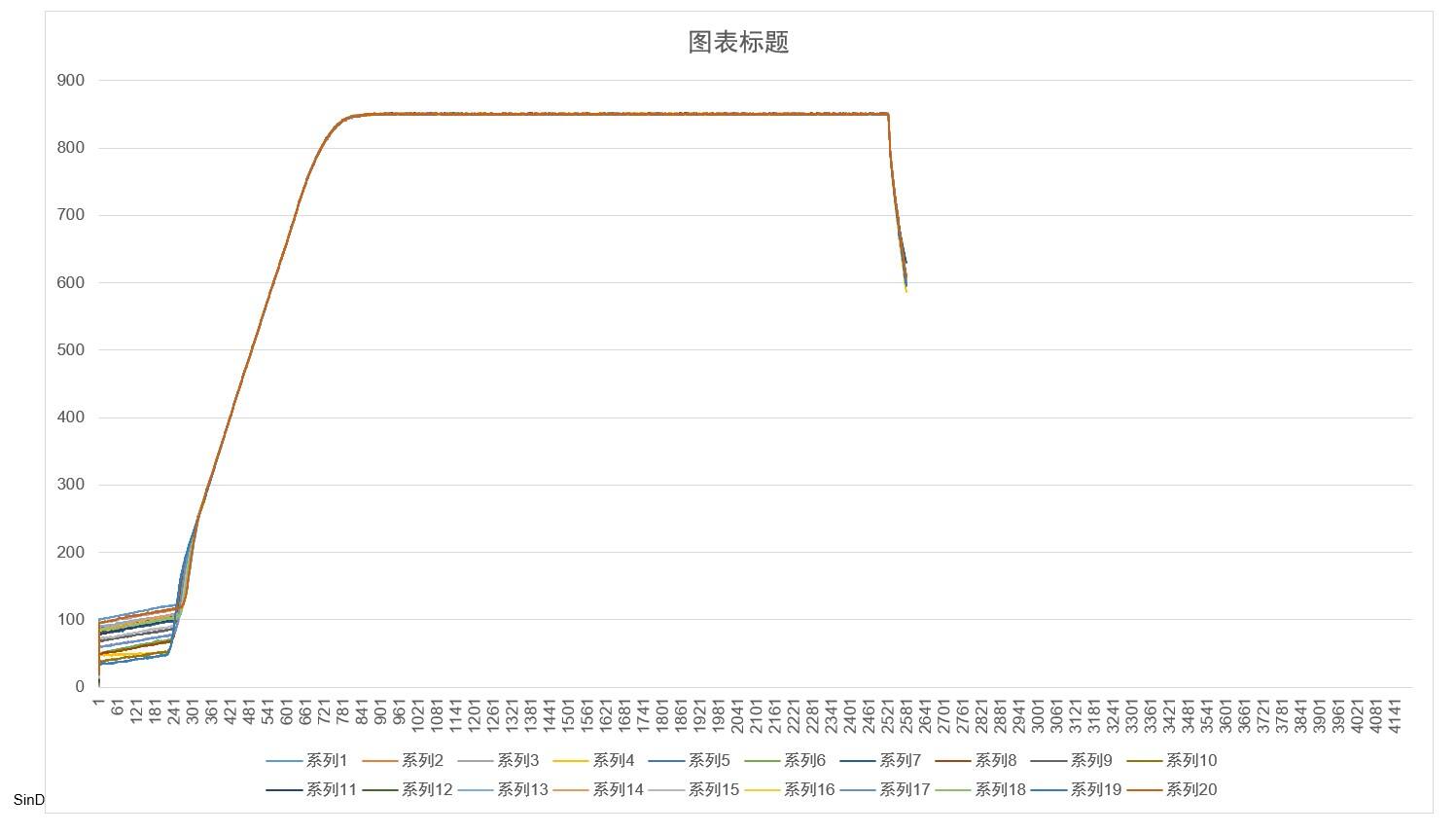

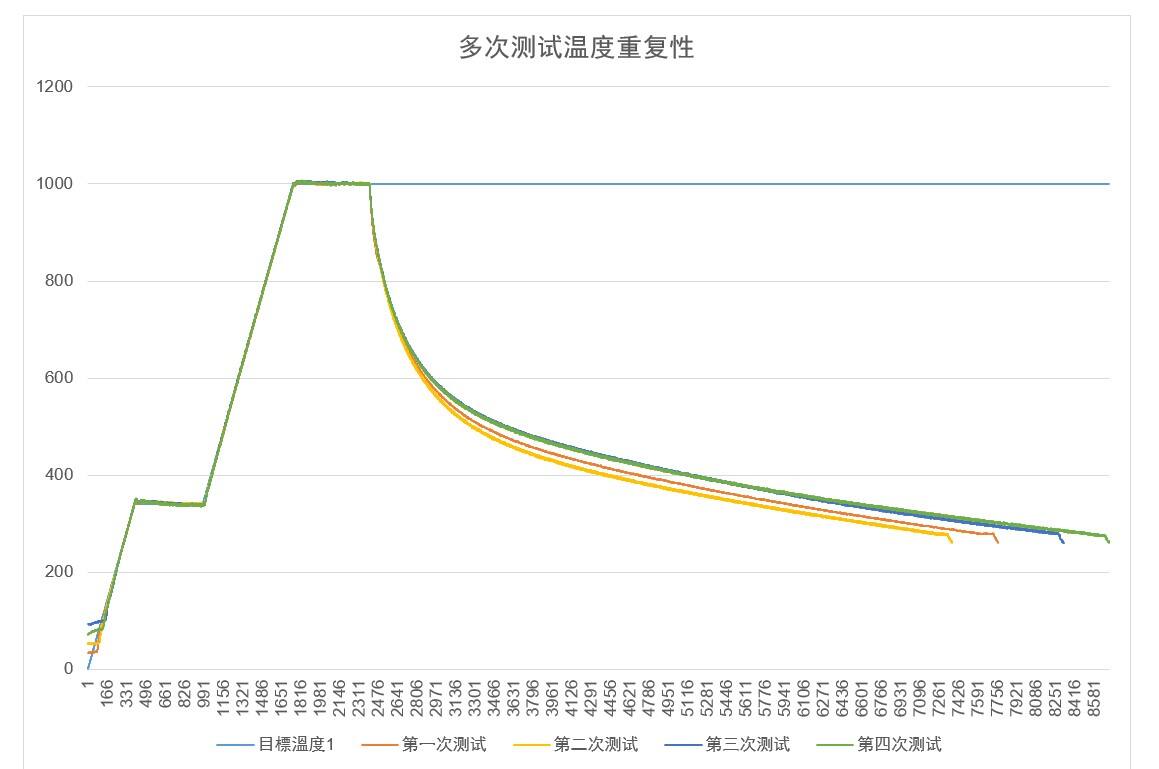

Coincidence of 20th degree curves:

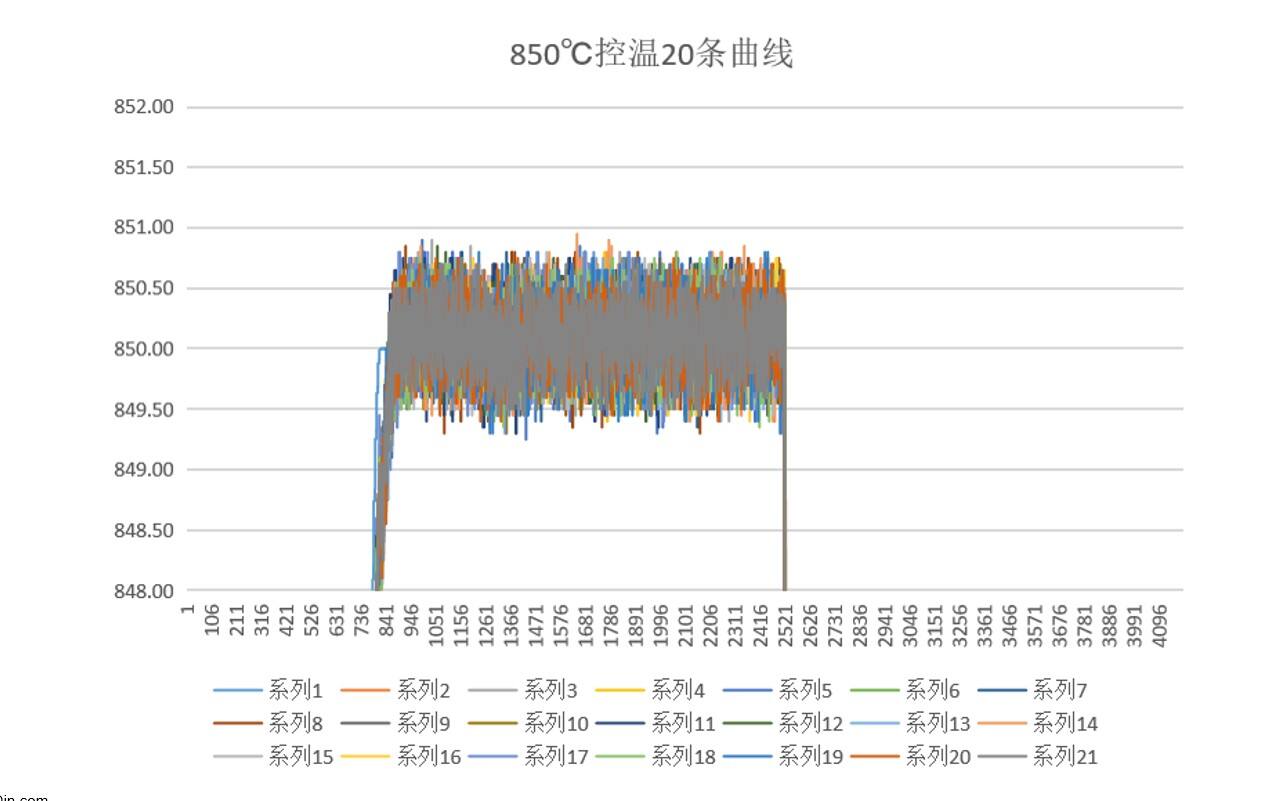

20 curves for temperature control at 850 ℃

Coincidence of 20 average temperature curves

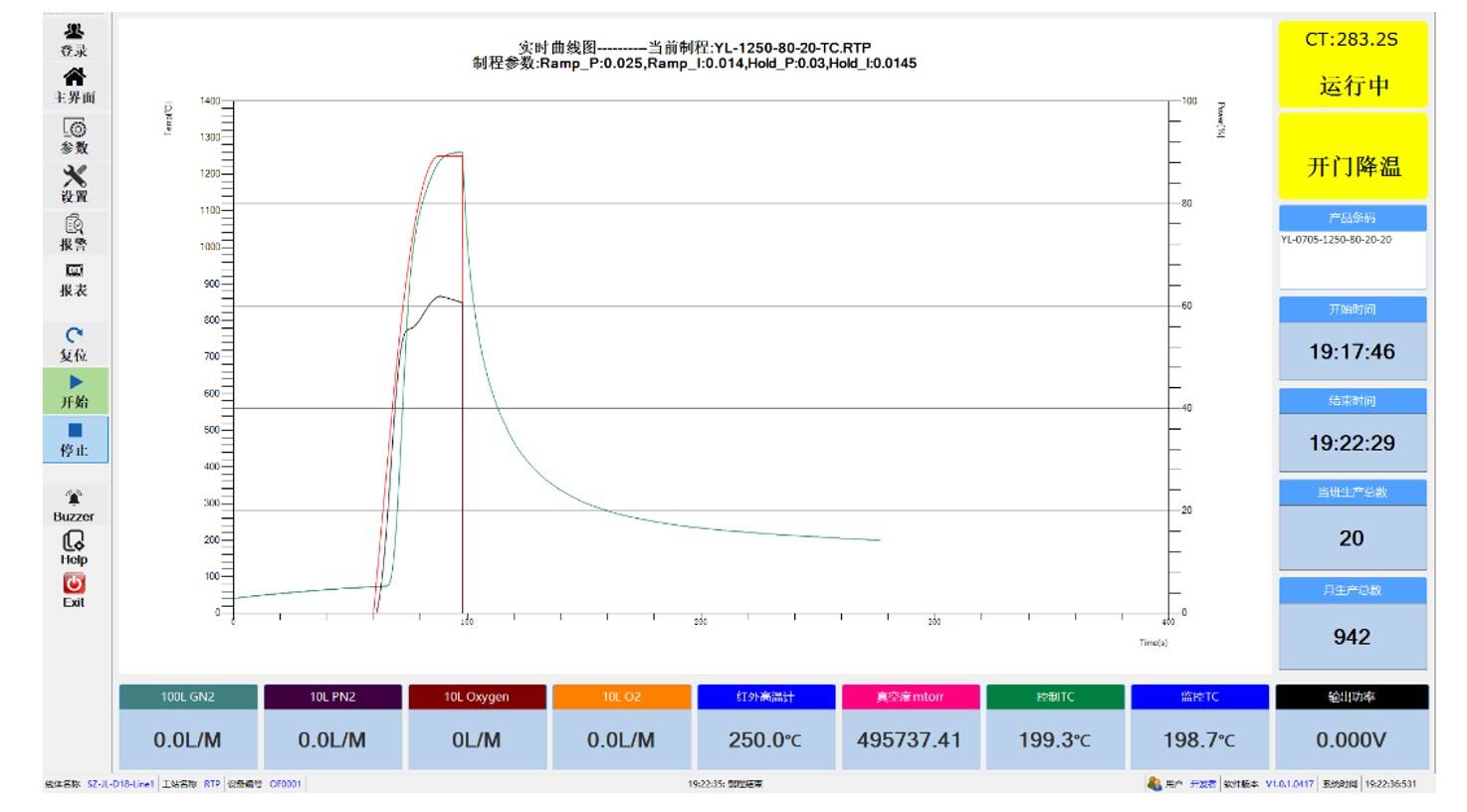

1250 ℃ temperature control

RTP temperature control 1000 ℃ process

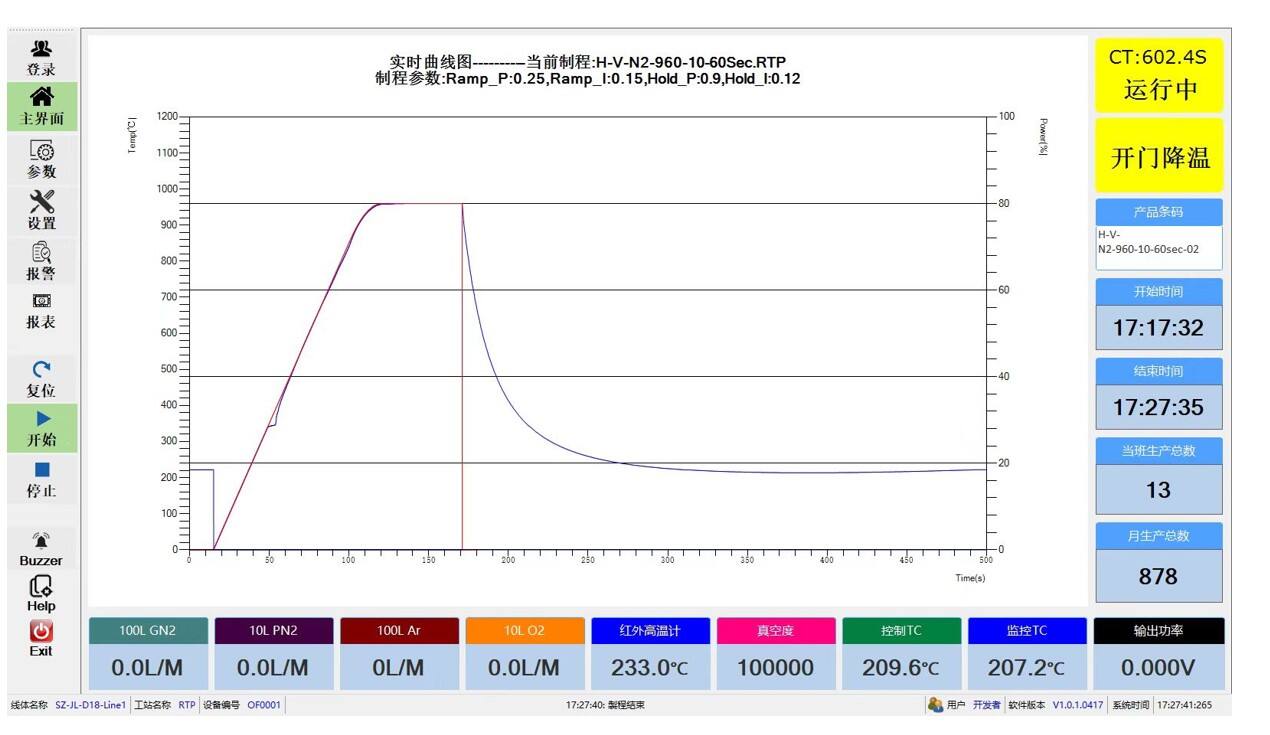

960 ℃ process, controlled by infrared pyrometer

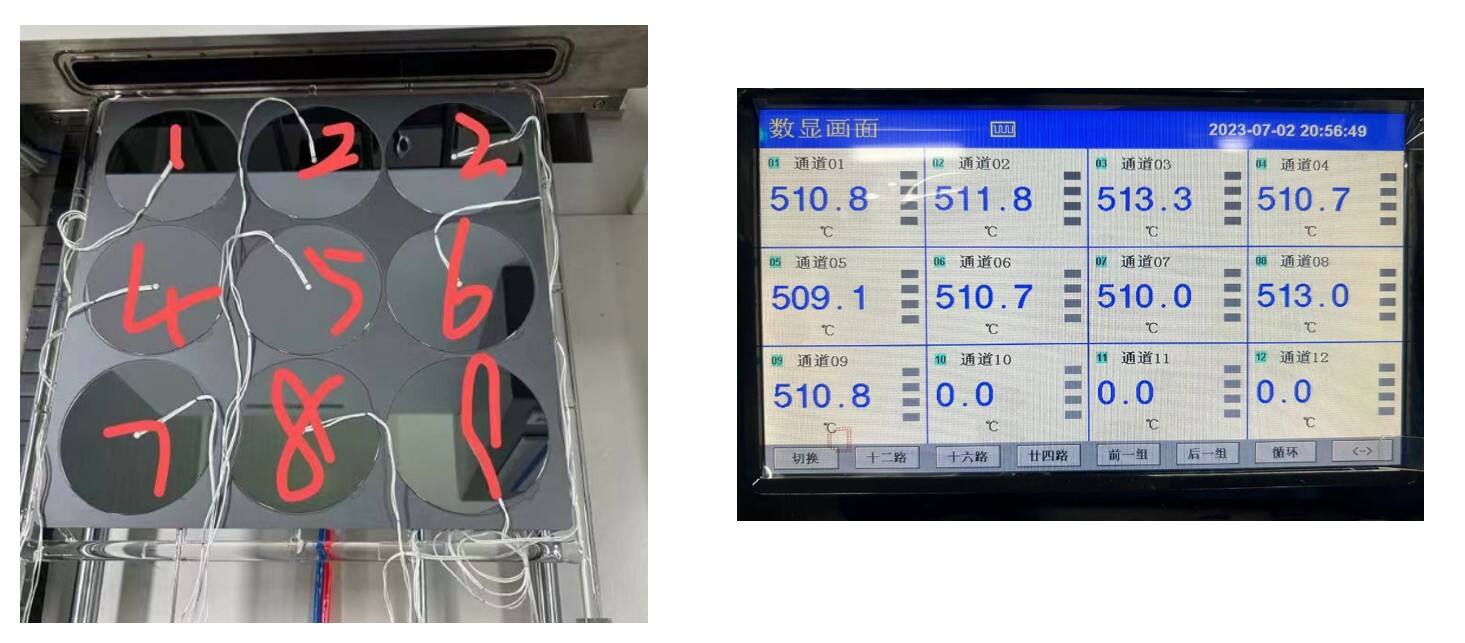

LED process data

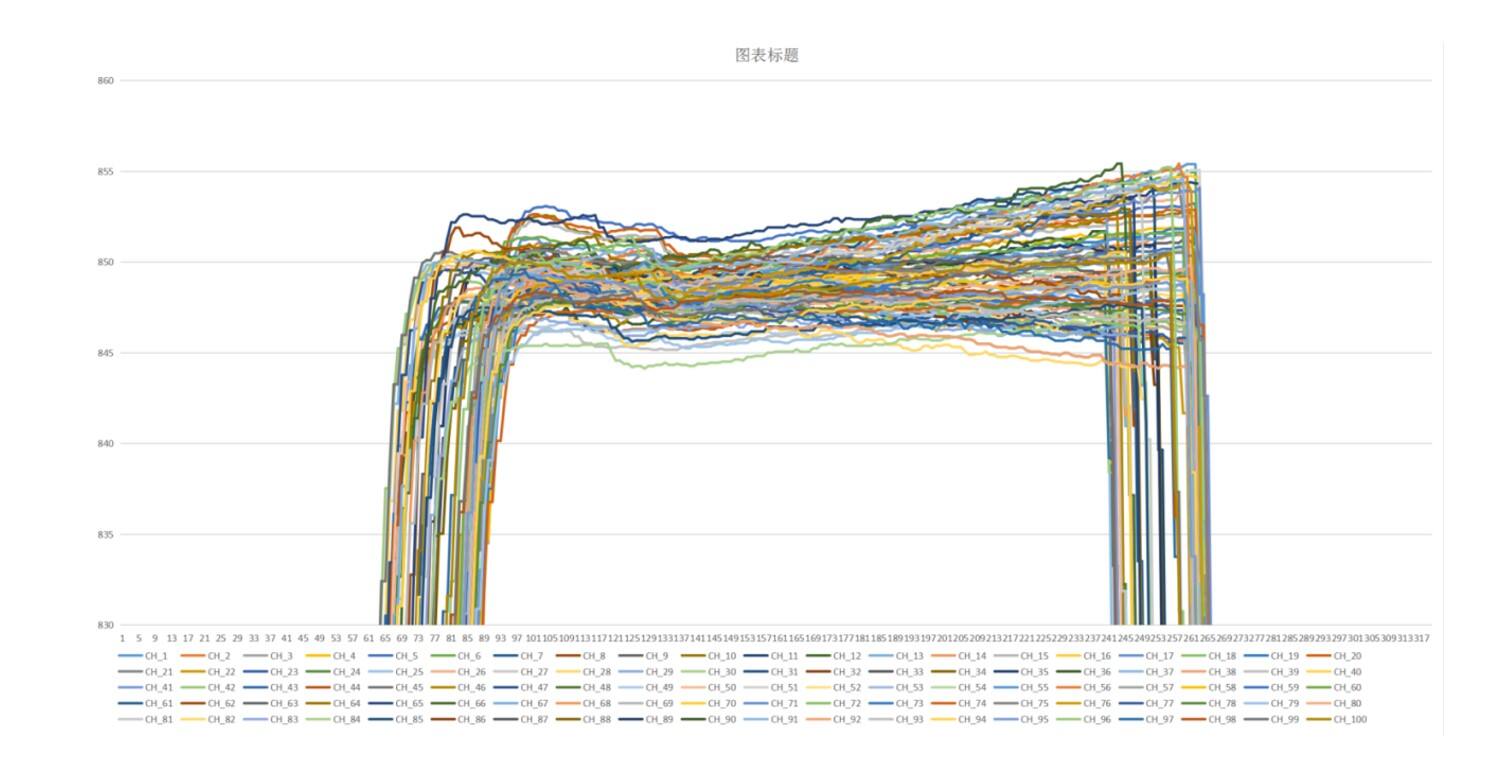

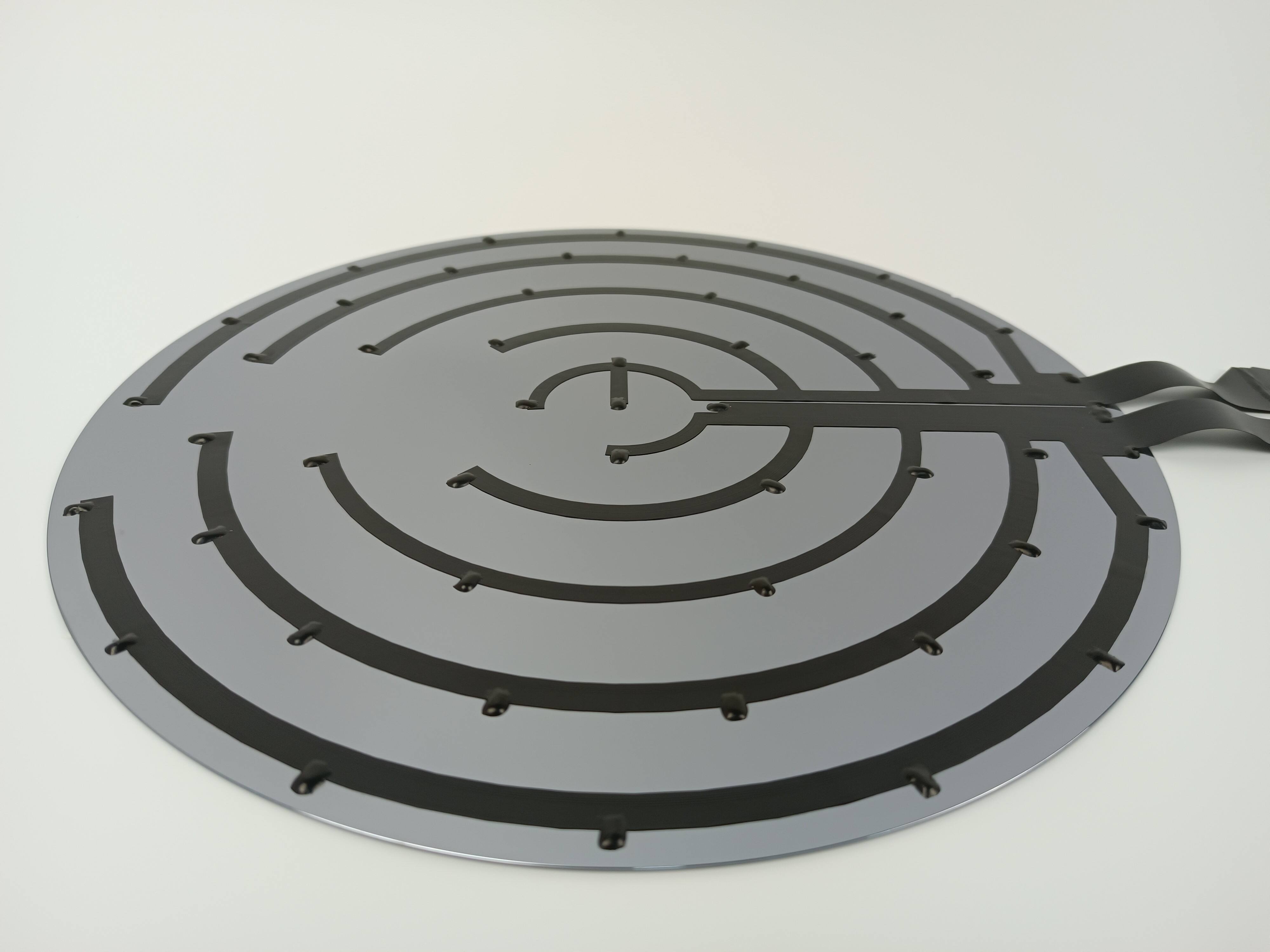

RTD Wafer is a temperature sensor that uses special processing techniques to embed temperature sensors (RTDs) at specific locations on the surface of a wafer, enabling real-time measurement of surface temperature on the wafer.

Real temperature measurements at specific locations on the wafer and the overall temperature distribution of the wafer can be obtained through RTD Wafer; It can also be used for continuous monitoring of transient temperature changes on wafers during the heat treatment process.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved