Model |

MD-G25A |

MD-G25D |

MD-G31 |

MD-G33 |

|||||

Exposure type |

One side |

Double side alignment and double side exposure |

|||||||

Exposure mode |

Contact hard, soft and non-contact proximity |

||||||||

Exposure head quantity |

1 Exposure head |

2 Exposure head |

|||||||

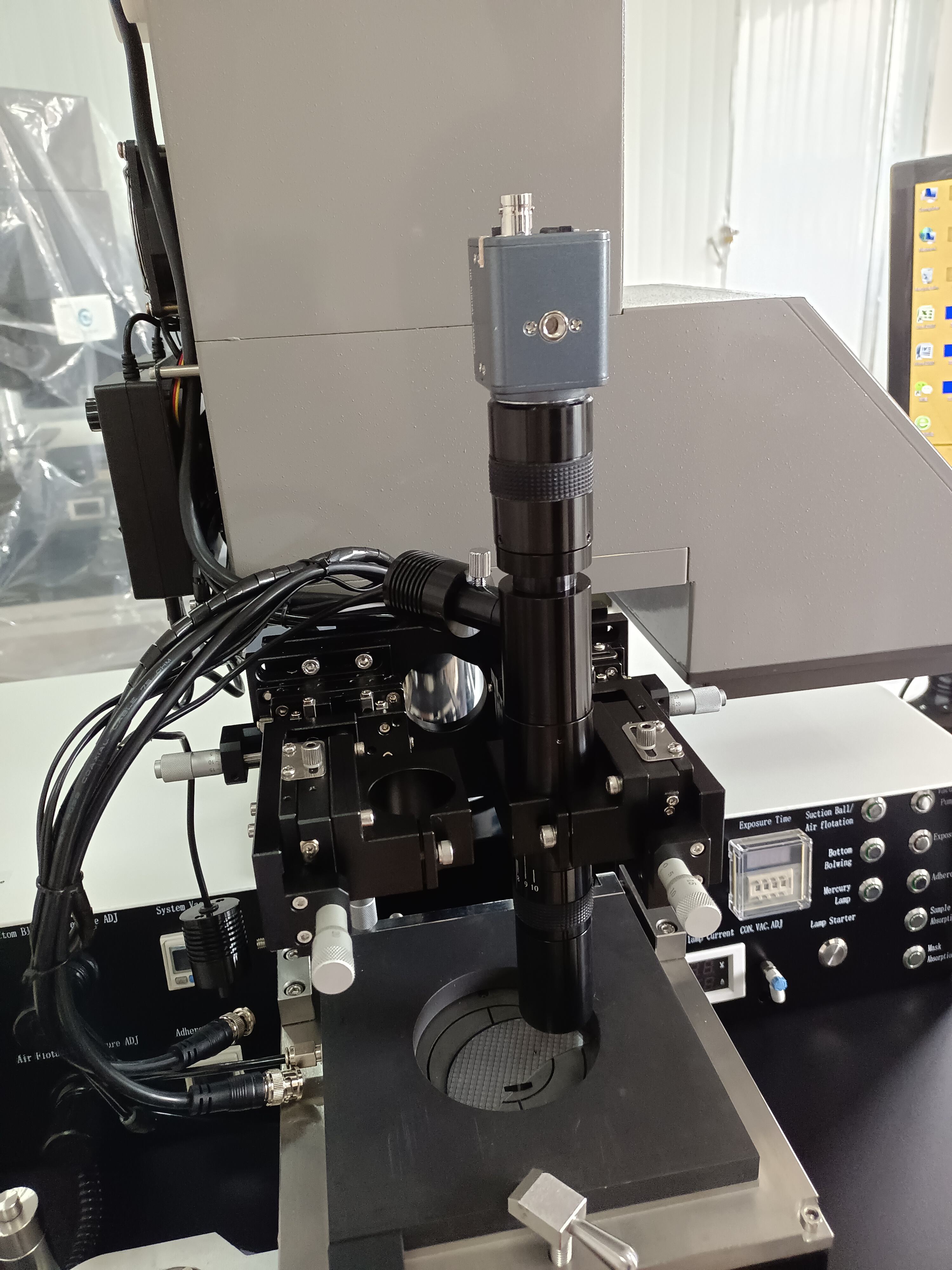

Type of light source |

GCQ350 spherical mercury lamp |

LED UV exposure head |

|||||||

Cooling method |

Air cooling |

||||||||

Exposure area |

Φ100mm |

110×110mm |

Φ100mm |

150mm×150mm |

|||||

Exposure mode |

Compatible with contact hard, soft |

||||||||

Exposure unevenness |

Φ100mm<±3%<>

|

≤±3% |

|||||||

Exposure resolution |

2μm |

1 μm |

|||||||

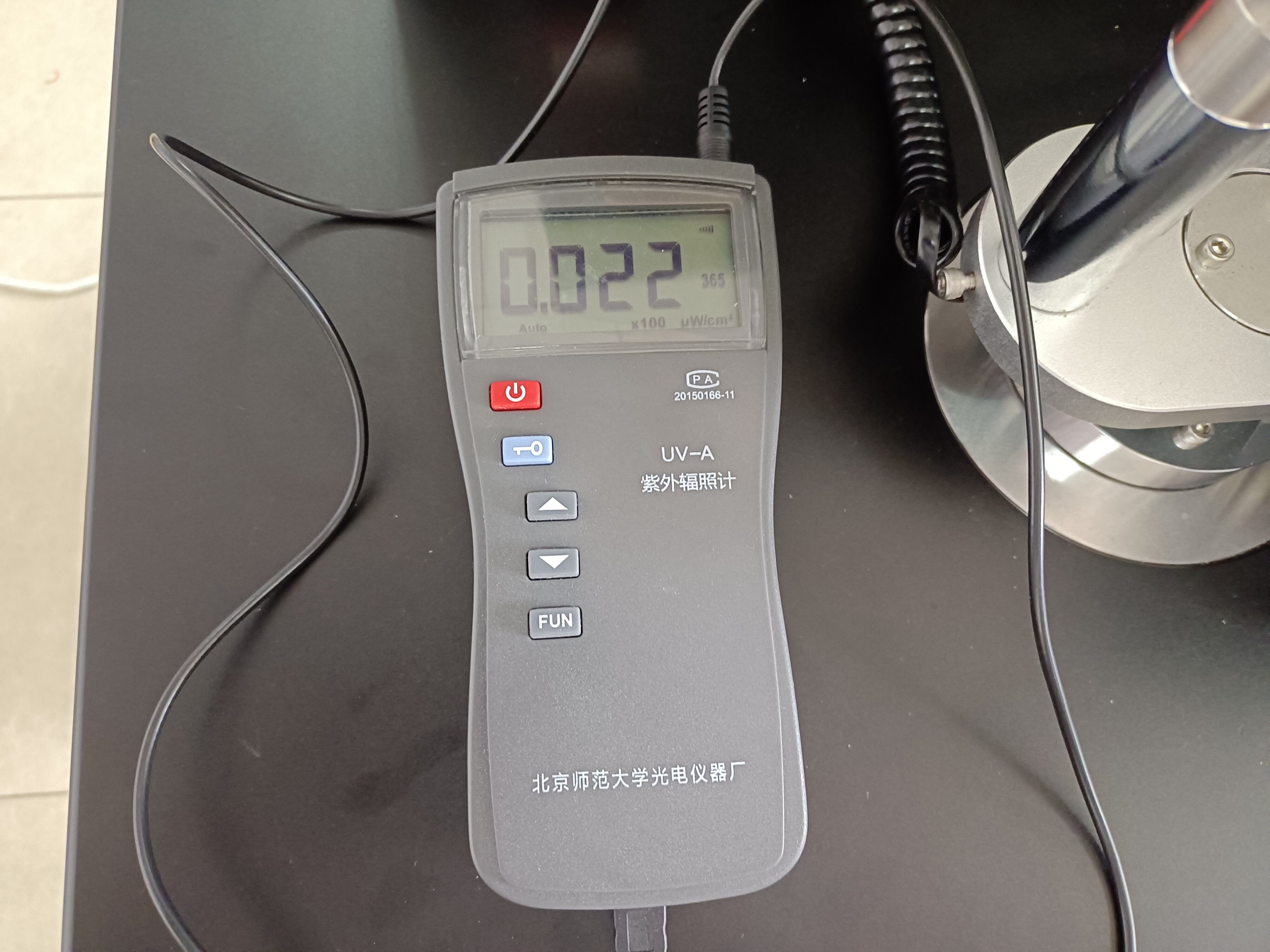

Beam intensity(365 nm) |

≥6mw/ cm² |

≤40mw/cm2 |

≥5mw/cm2 |

0~30mw/cm2 |

|||||

Beam inhomogeneity |

≤±4% |

≤±3% |

|||||||

UV light maximum deviation angle |

4° |

3° |

|||||||

Lighting range |

≤Φ117mm |

Φ117mm |

≤Φ117mm |

Front and back ≥ Φ115mm |

|||||

Wedge error compensation mode |

Hemispherical automatic compensation |

Auto elimination |

3 point automatic compensation |

||||||

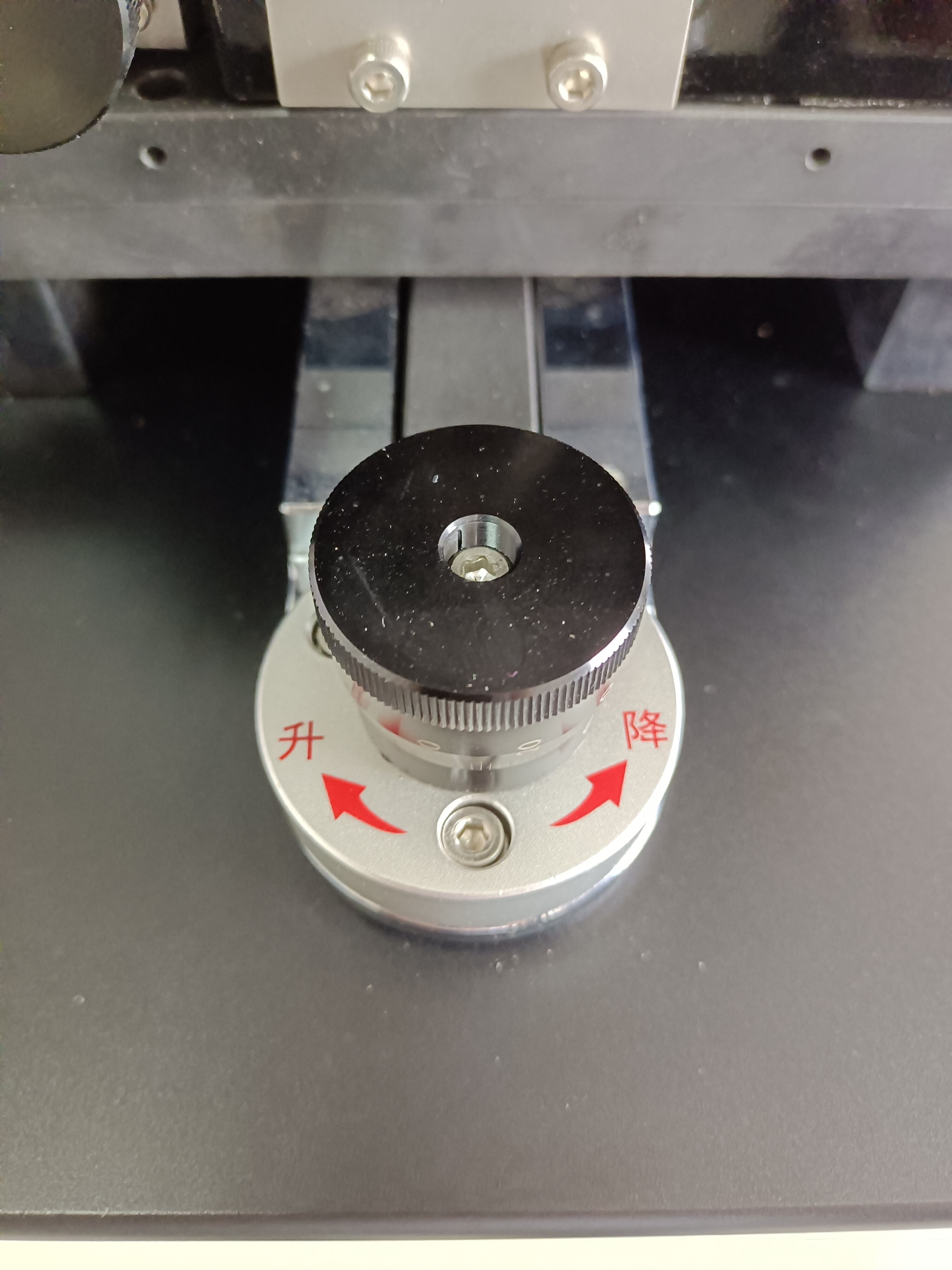

The travel of the X and Y axes |

±4mm |

±5mm |

±4mm |

±5 mm |

|||||

The travel of the θ |

±3° |

≤5° |

≤±5º |

≤0.5° |

|||||

XYZ substrate displacement resolution |

0.5µm |

0.3µm |

0.3µm |

0.01µm |

|||||

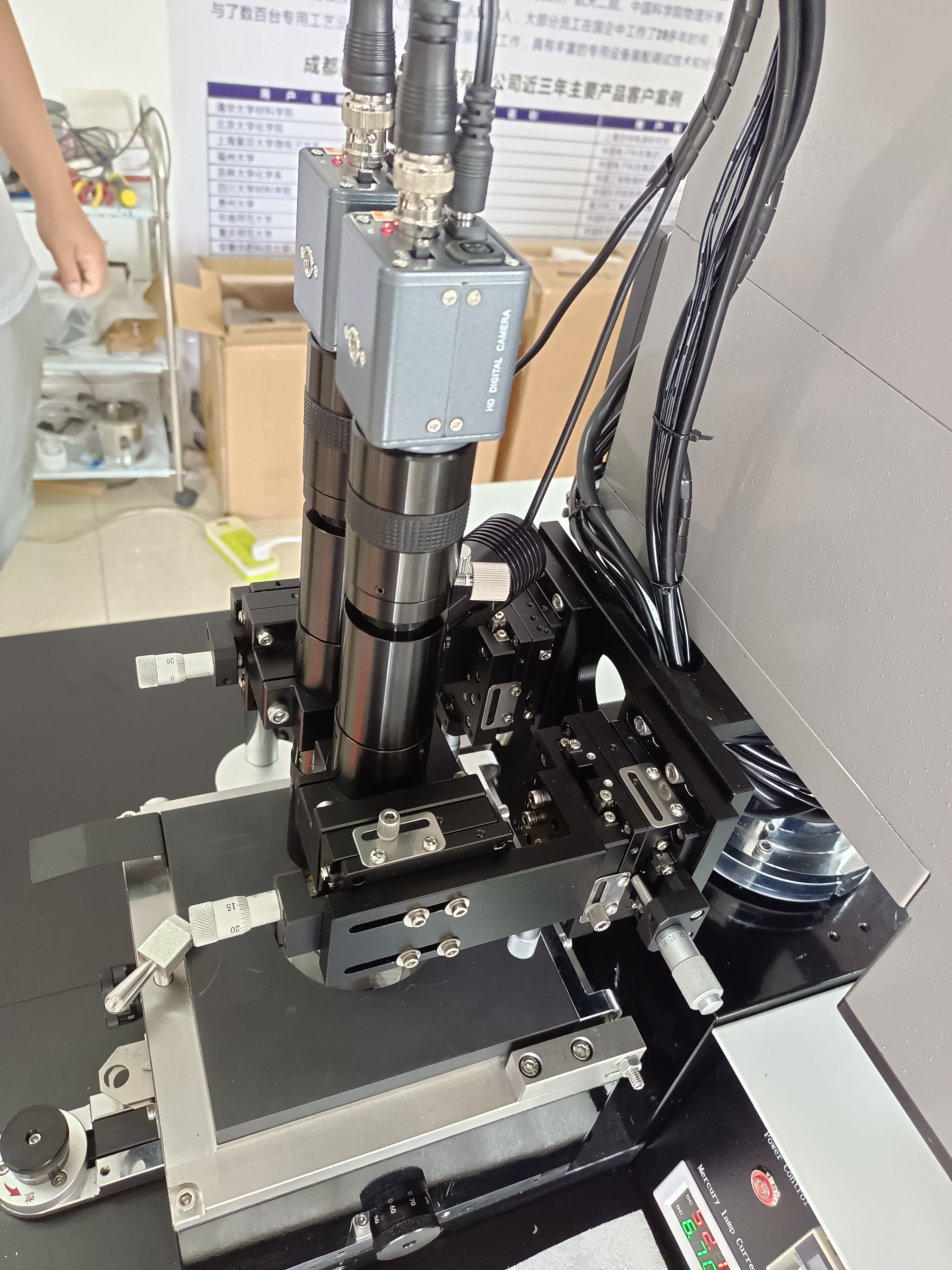

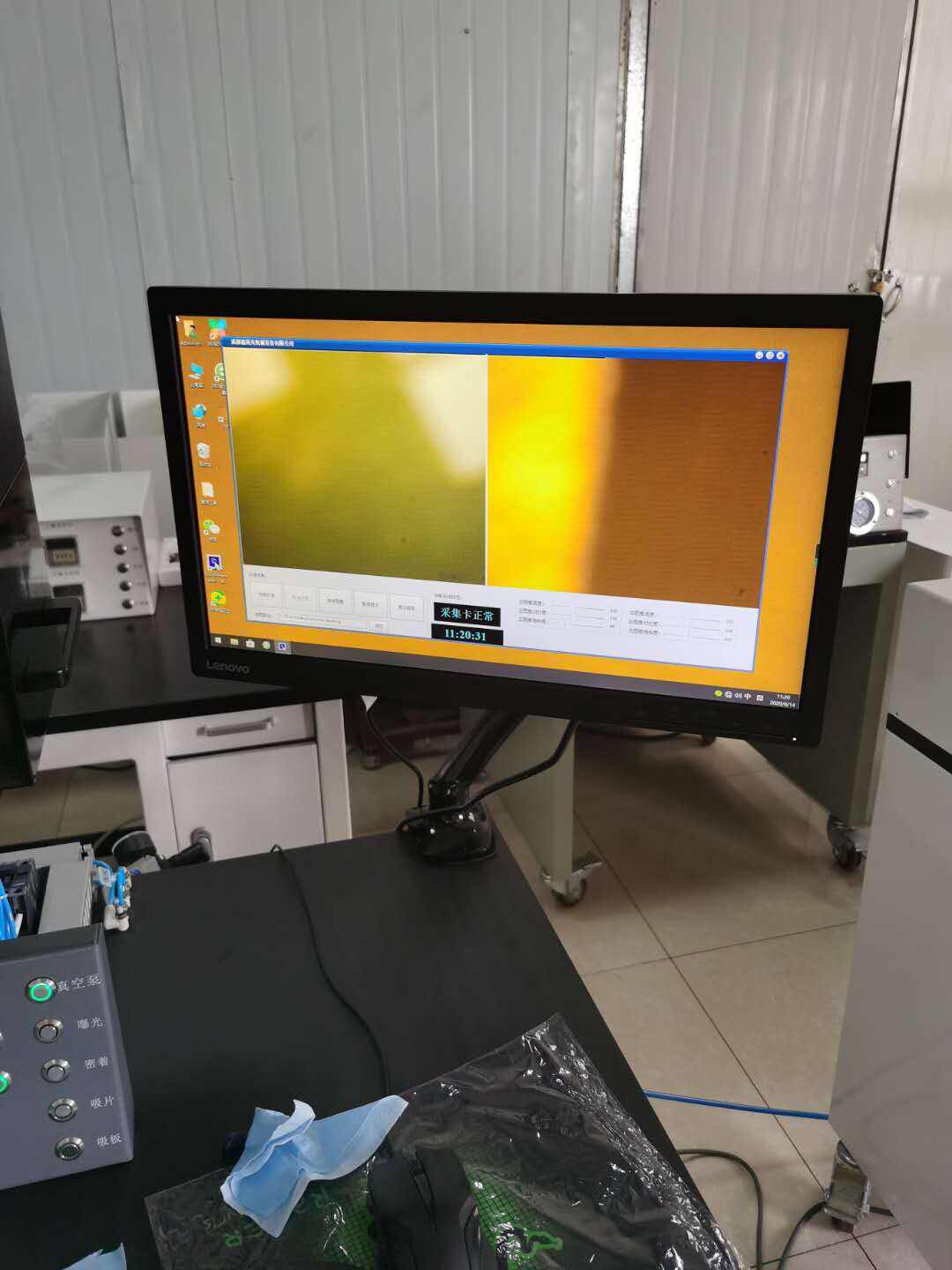

Microscope system |

Two single barrel microscopes /Two CCD cameras |

||||||||

Display size |

15 inches |

||||||||

Imaging system resolution |

2µm |

1.5µm |

1.5µm |

1.5µm |

|||||

Mask and the substrate measurement distance |

0.5 µm |

0.3 µm |

|||||||

Diagonal dimension of CCD target surface |

1/3,(6mm) |

40mm~110mm |

|||||||

Setting table size |

≤ Square 5*5 inch(Customizable specifications) |

||||||||

Substrates size |

Φ 100mm or 100*100mm square |

60*49.5mm square |

2”-4” |

1"x1"-5"x5" |

|||||

Substrate thickness |

1-3mm |

≤5 mm |

1-3mm |

≤5 mm |

|||||

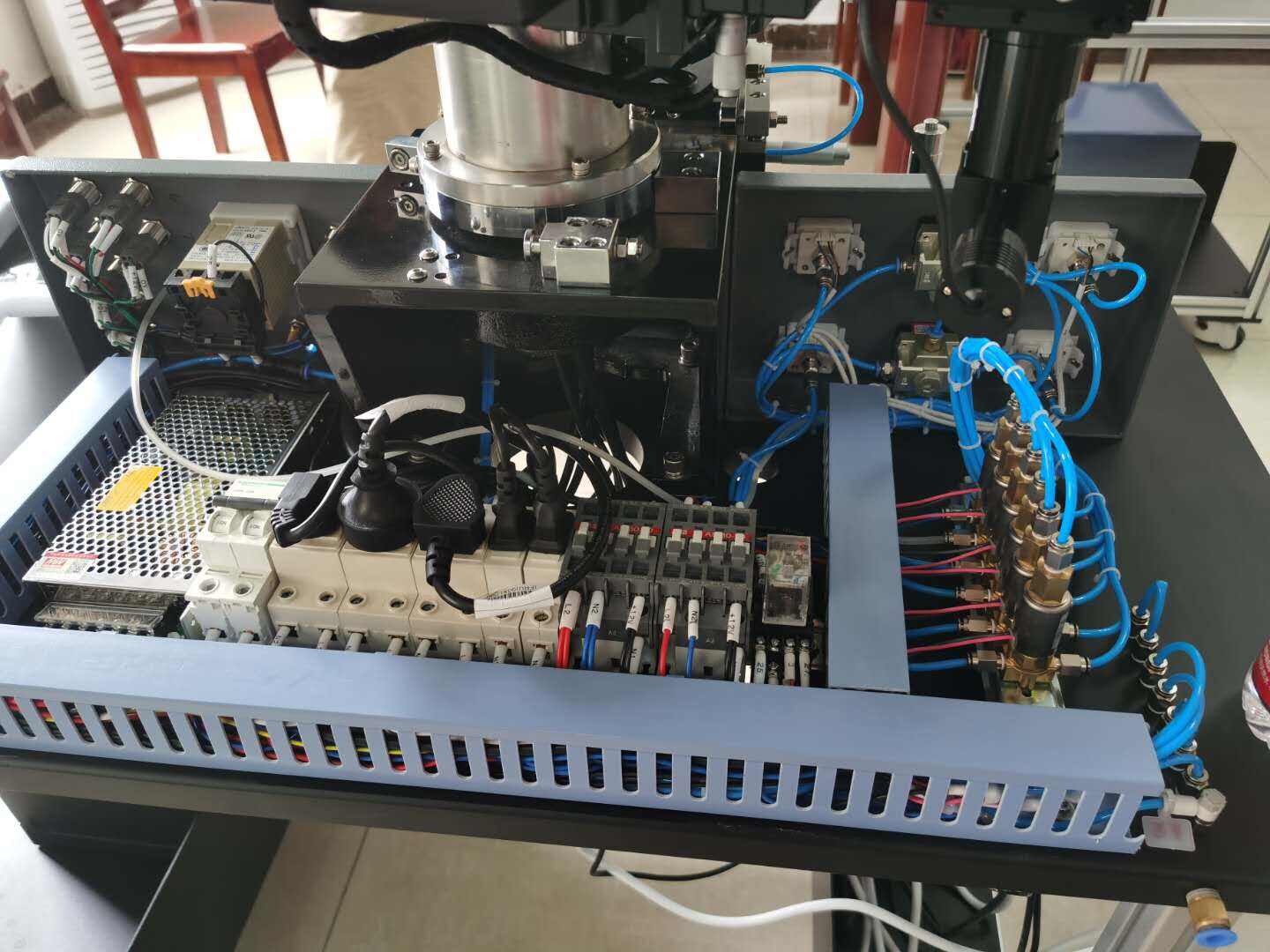

Vacuum pump |

Oil free mute(-0.07~-0.08MPα) |

||||||||

Clean compressed air |

≥0.4MPα |

||||||||

Power Supply |

AC 220V±10% 50HZ 1.5KW |

||||||||

Clean room grade |

Class 100 |

||||||||

Clean room temperature |

25℃±2℃ |

||||||||

Relative humidity of clean room |

≤60% |

||||||||

Vibration amplitude of clean room |

≤4μm |

||||||||

Equipment size |

1300 ×720×1600mm |

1500 ×800×1600mm |

|||||||

Equipment weight |

200kg |

280kg |

|||||||

Minder-Hightech brings you an advanced technology for photolithography through Aligner/Alignment Machine.

Are you struggling with not enough accuracy while printing circuits on your electronic products? With Minder-Hightech's Aligner/Alignment Machine, you can rest knowing that you will achieve high-level precision on your printed circuits production.

With this revolutionary item, you can seamlessly transfer a high-resolution image onto a product using photolithography. This machine guarantees accuracy through an operational system of aligning the material to the image.

After the pictures were printed and uploaded, the machine calculates the amount of exposure required and how the material is aligned with mention of the pictures. This calculation is done by using the latest computer software that can be updated to meet up with the technological development in the production industry.

It will allow you to make a wide range, including microcircuits, radiofrequency (RF) circuits, and built-in circuits. The unit can produce the best etch depth, track width, and layer-to-layer alignment through the addition of various complementary procedures, such as chemical etching and electroplating.

Our product’s advantage lies in its capability to produce high alignment, which guarantees that patterns are situated with great precision on the material. You can conveniently print many complicated designs without any deformities.

It is user-friendly, compact, and efficient, making it suitable for various manufacturing facilities or company's size. Additionally, our device comes with a manual upkeep and on-site training with our team of tech support staff.

Minder-Hightech’s Aligner/Alignment Machine uses photolithography technology to help you achieve the best results while printing your circuits. Experience a new level of technology that offers you high accuracy and precision that cannot be matched by traditional printing methods. Minder-Hightech’s Aligner/Alignment Machine is what your manufacturing company needs to stay a step ahead of the competition. Get in touch with us today to enjoy the benefits of the best Aligner/Alignment Machine technology in the market.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved