Minder-Hightech

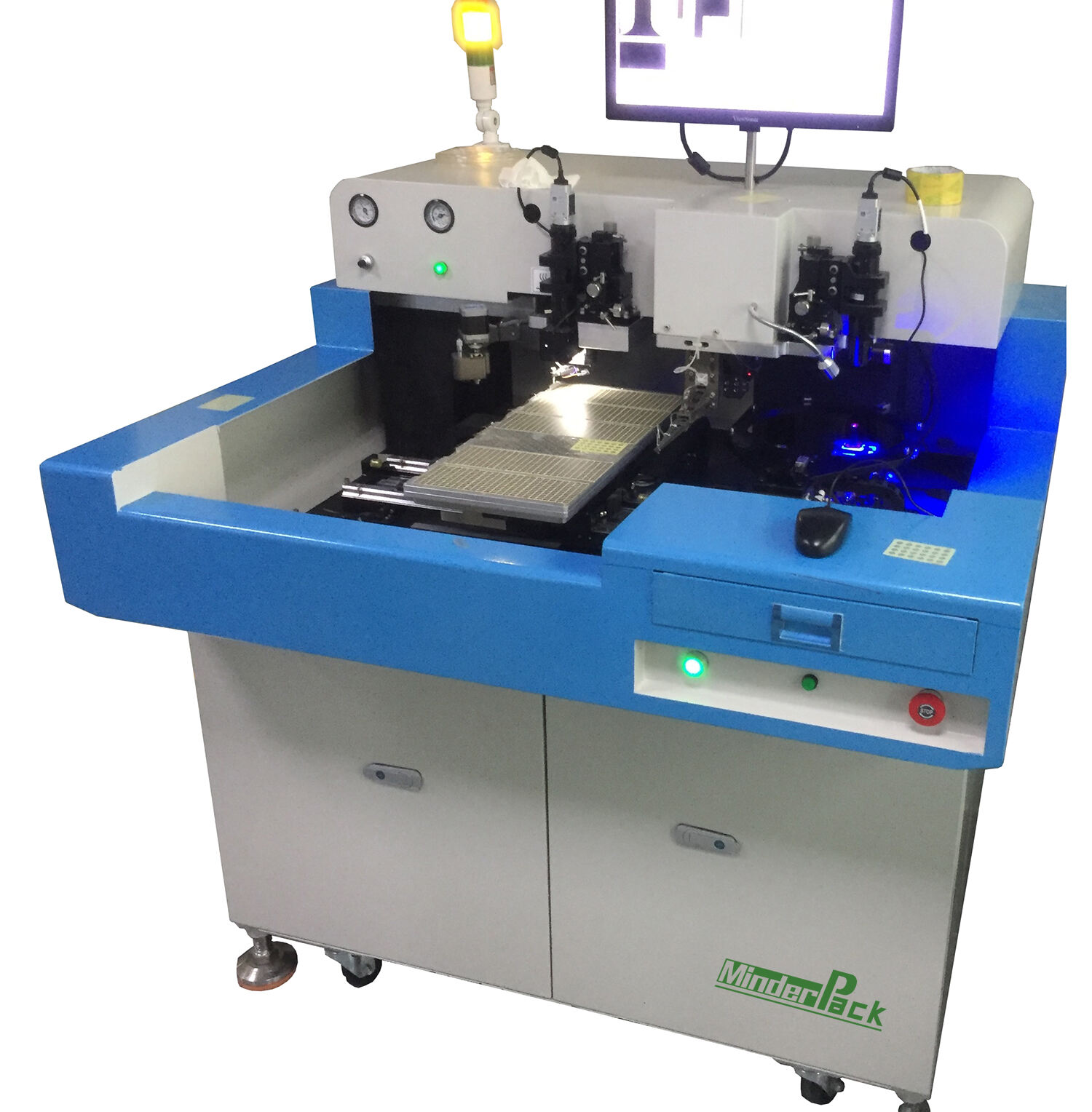

The Automatic Die Bonder could be the solution ideal accuracy die bonding applications. Its advanced functions help it become choice great companies are looking for dependable and semiconductor packaging gear efficient.

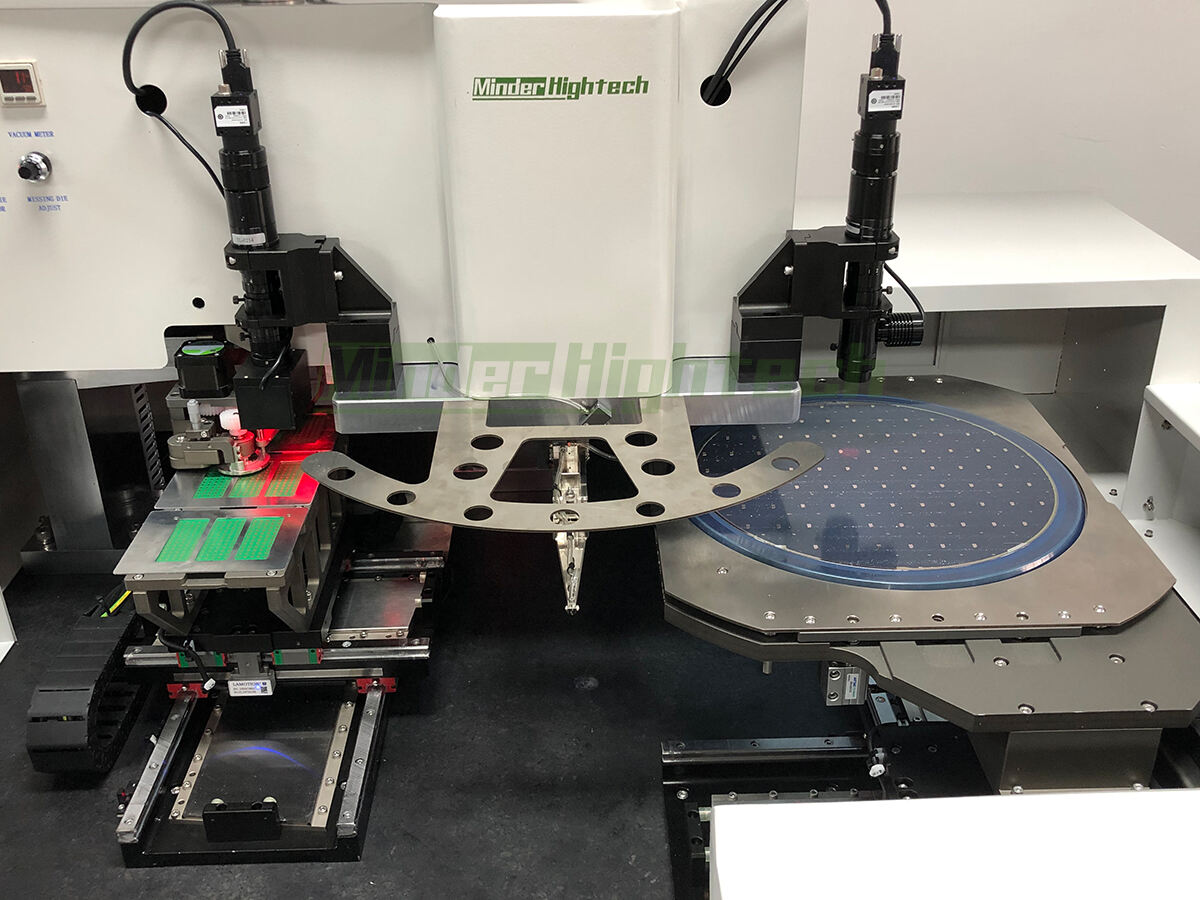

The Automatic die bonder automatic upload and download MD-JC360i MD-JC380i is sold with automated upload and down load functionality, ensuring effectiveness optimal simplicity of use. The MD-JC360i and MD-JC380i models give you a robust and design versatile can handle many different applications.

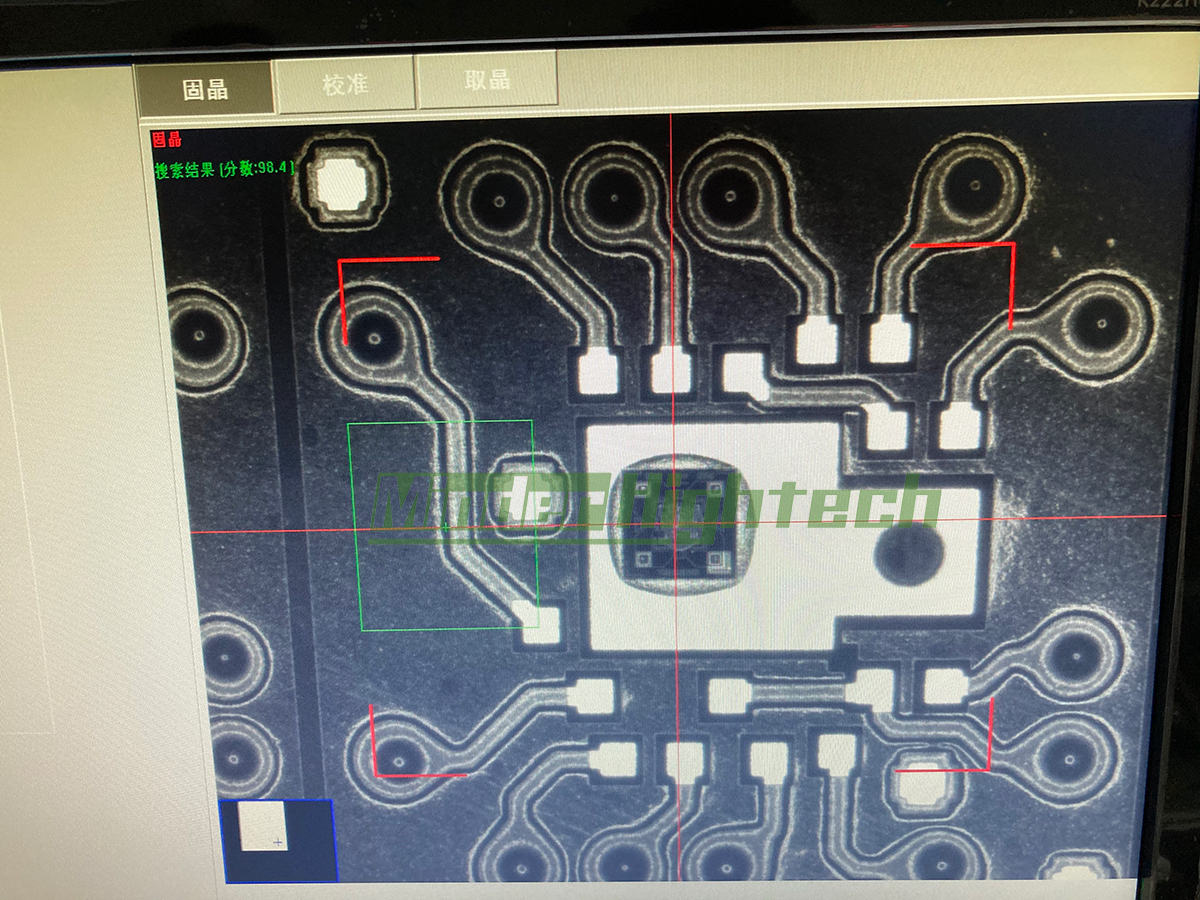

product provides excellent procedure simple its user-friendly software. The Minder-Hightech Automatic Die Bonder has an eyesight enhanced featuring real-time technology positioning. guarantees the amount greatest of precision and persistence with every relationship.

The Automatic die bonder automatic upload and download MD-JC360i MD-JC380i is made to manage package different, rendering it well suited for many jobs. It may manage package sizes just as much as 30 mm by 30 mm when it comes to model MD-JC360i or higher to 40 mm by 40 mm for the model MD-JC380i.

Product the most choices are efficient the marketplace, having a throughput most of the real option to 3000 UPH when it comes to MD-JC360i and up to 5000 UPH when it comes to MD-JC380i. number of performances can be as a result of its multi-die ability, and may manage as much as four dies simultaneously, reducing relationship some time efficiency increasing.

The Automatic die bonder automatic upload and download MD-JC360i MD-JC380i comes with a variety of features made for effortless upkeep and fast changeovers. These generally include a relationship installation tool-less programmable die-ejector pins, enabling simple and fast modification to fulfill your specific needs.

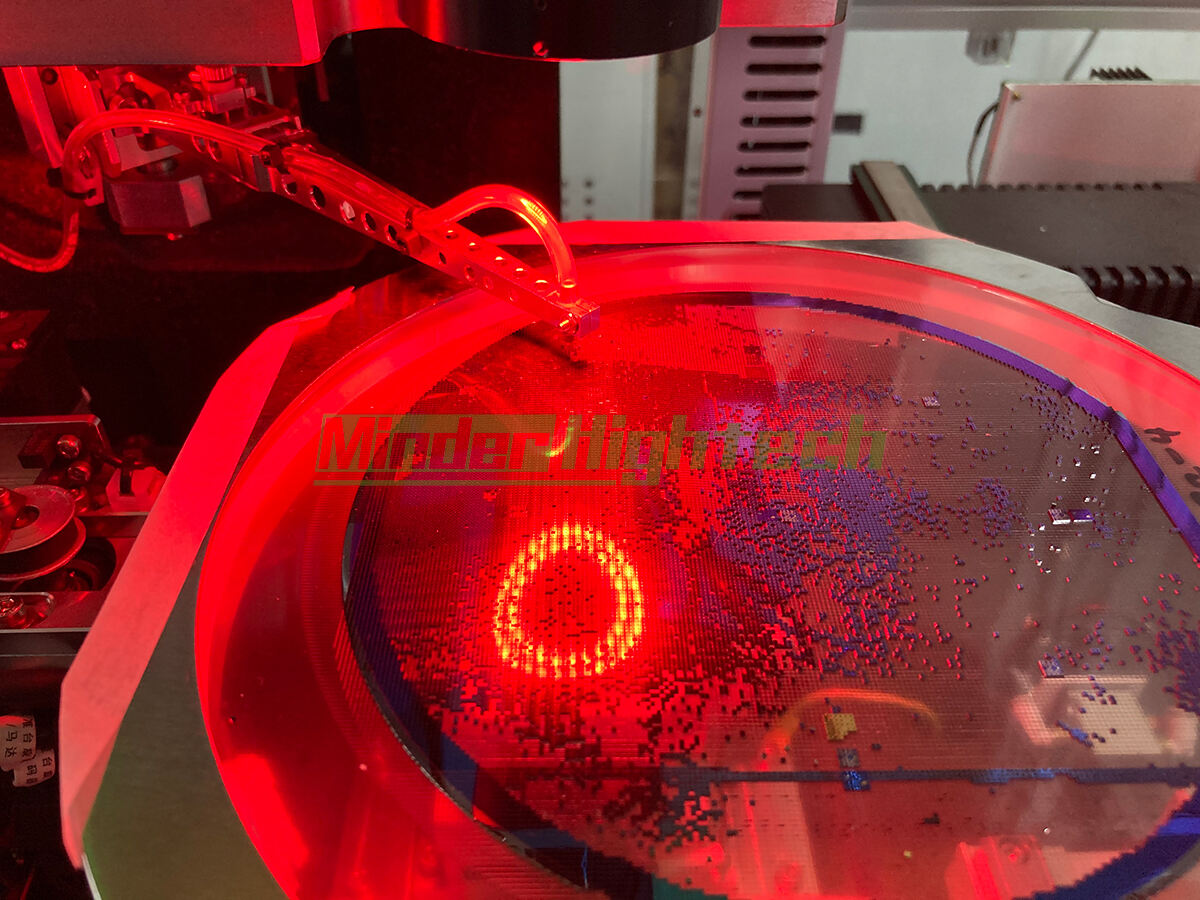

The Automatic die bonder automatic upload and download MD-JC360i MD-JC380i features a vacuum enhanced system eliminates any possible contaminants through the bonding area to make maximized performance and dependability.

MD-JC360i |

||

Solid Crystal Worktable (Linear Module) |

||

Worktable strok: |

100x300mm |

|

Resolution: |

1μm |

|

Die Workbench Linear Module |

||

XY stroke: |

8"*8" |

|

Resolution: |

1μm |

|

Wafer placement accuracy |

||

Adhesive die position: |

±2mil |

|

Rotation accuracy: |

±3° |

|

Dispensing module: |

Swing arm dispensing + heating system,Dispensing needle set can be exchanged by single or multiple needles |

|

PR System |

||

Method: |

256 grey levels |

|

Detection: |

ink墨点/chipping破晶/cracked die裂晶 |

|

Monitor: |

17"液晶LCD |

|

Monitor Resolution: |

1024*768 |

|

Optics System: |

Camera |

|

Optics Magnifier: |

0.7 times to 4.5 times |

|

Cycle Time: |

200MS/EA |

|

Loading and unloading module: |

Use vacuum sucker to automatically feed. Use box cartridge receipt to unloading. Pneumatic plate clamp, bracket width adjustment range of 25 ~ 90mm |

|

Voltage: |

AC220V/50HZ |

|

Air Source: |

minimum 6BAR |

|

Vacuum Source: |

700mmHG |

|

Power Consumpion: |

3000w |

|

Dimensions And Weight |

||

Weight: |

450kg |

|

Size(DxWxH): |

1200*900*1500mm |

|

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved