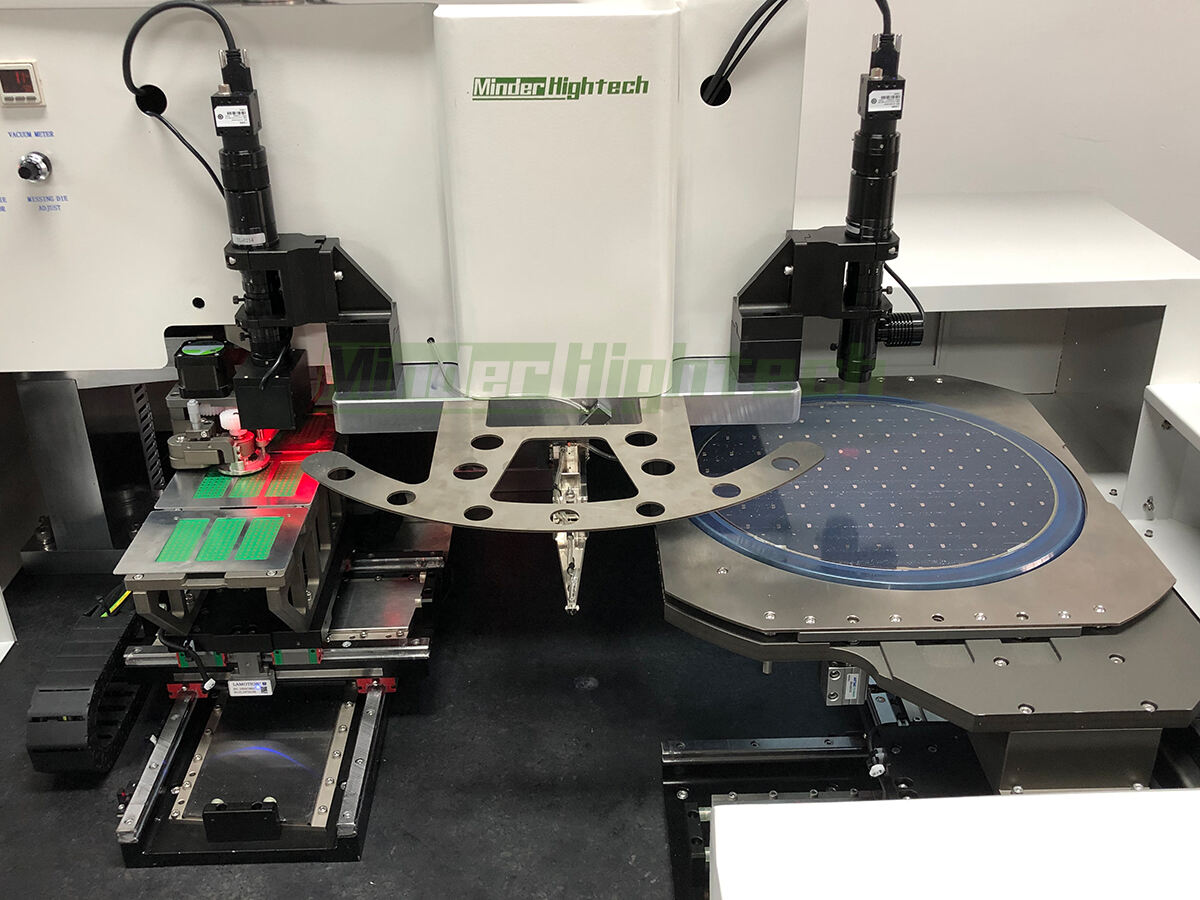

Bonding workstage | ||

Load ability | 1 piece | |

XY stroke | 10inch*6inch(working range 6inch*2inch) | |

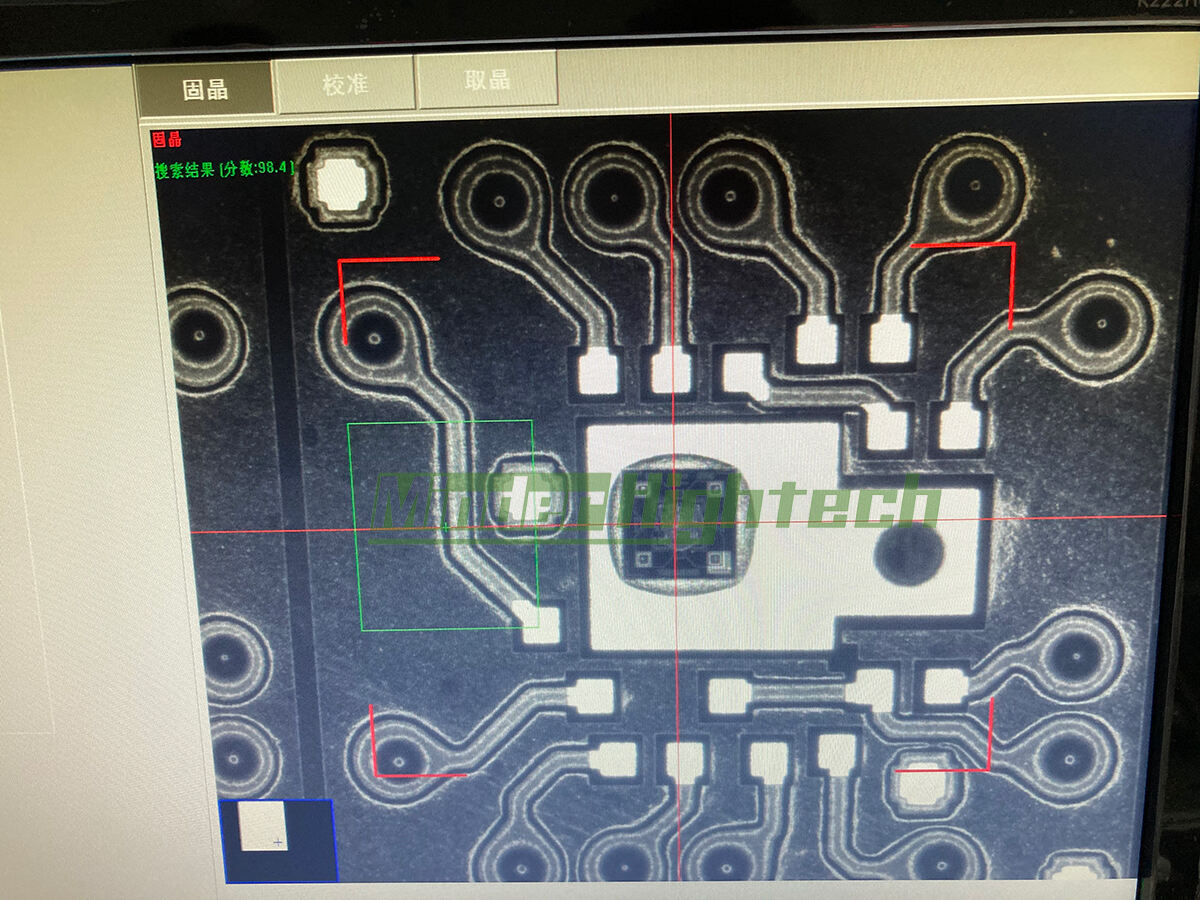

Accuracy | 0.2mil/5um | |

Dual work stage can feed continuously | ||

Wafer workstage | ||

XY travel stroke | 6inch*6inch | |

Accuracy | 0.2mil/5um | |

Wafer position accuracy | +-1.5mil | |

Angle accuracy | +-3 degree | |

Die dimension | 5mil*5mil-100mil*100mil |

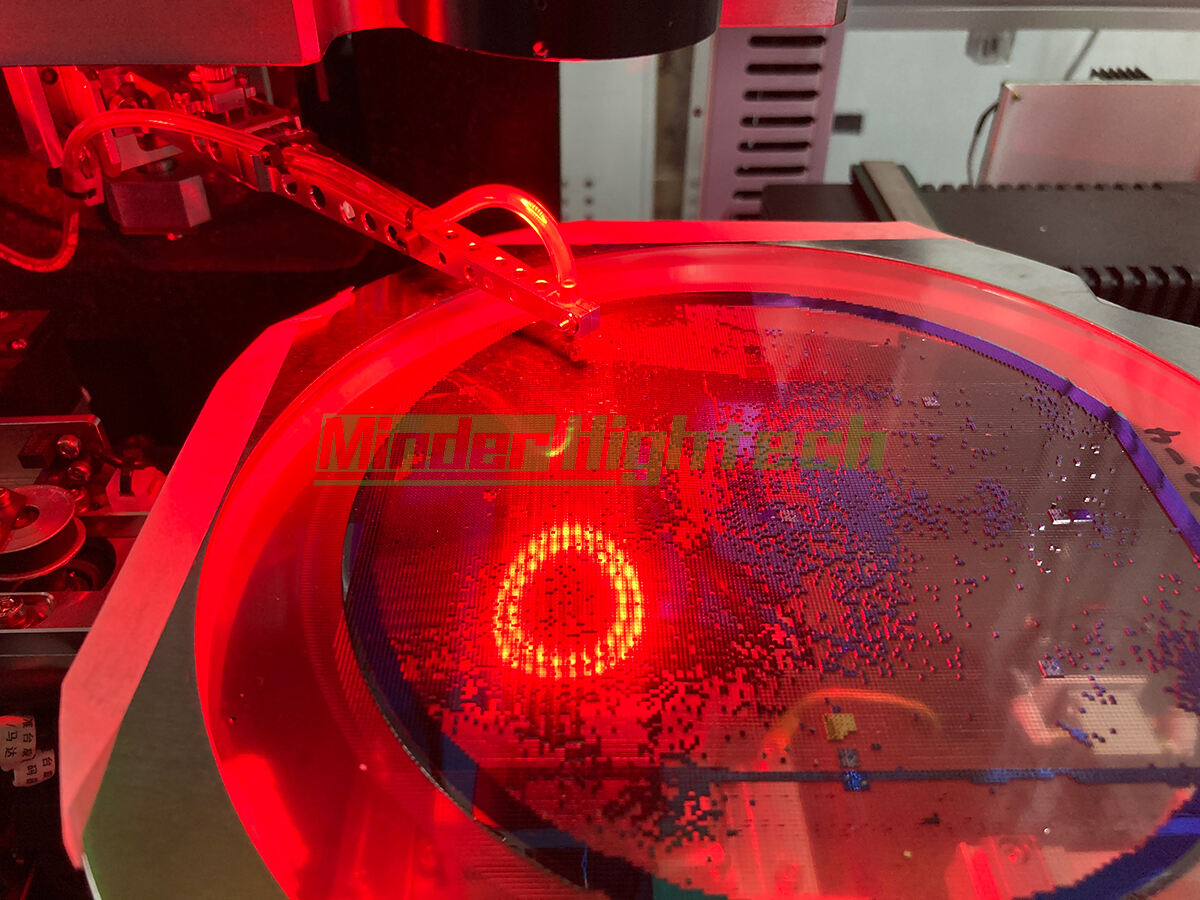

Wafer dimension | 6inch |

Picking up range | 4.5inch |

Bonding force | 25g-35g |

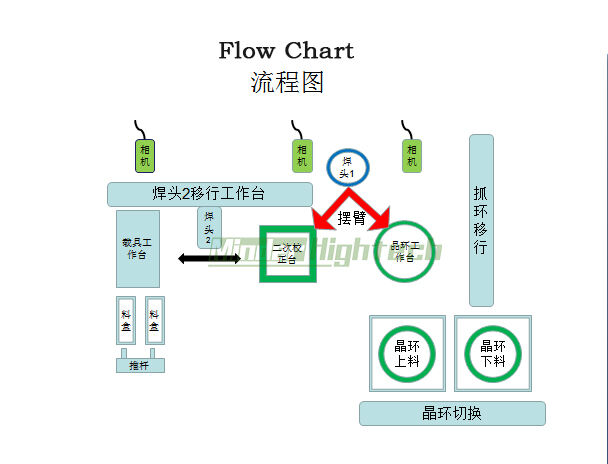

Multi wafer ring design | 4 wafer ring |

Die type | R/G/B 3type |

Bonding arm | 90degree rotary |

Motor | AC servomotor |

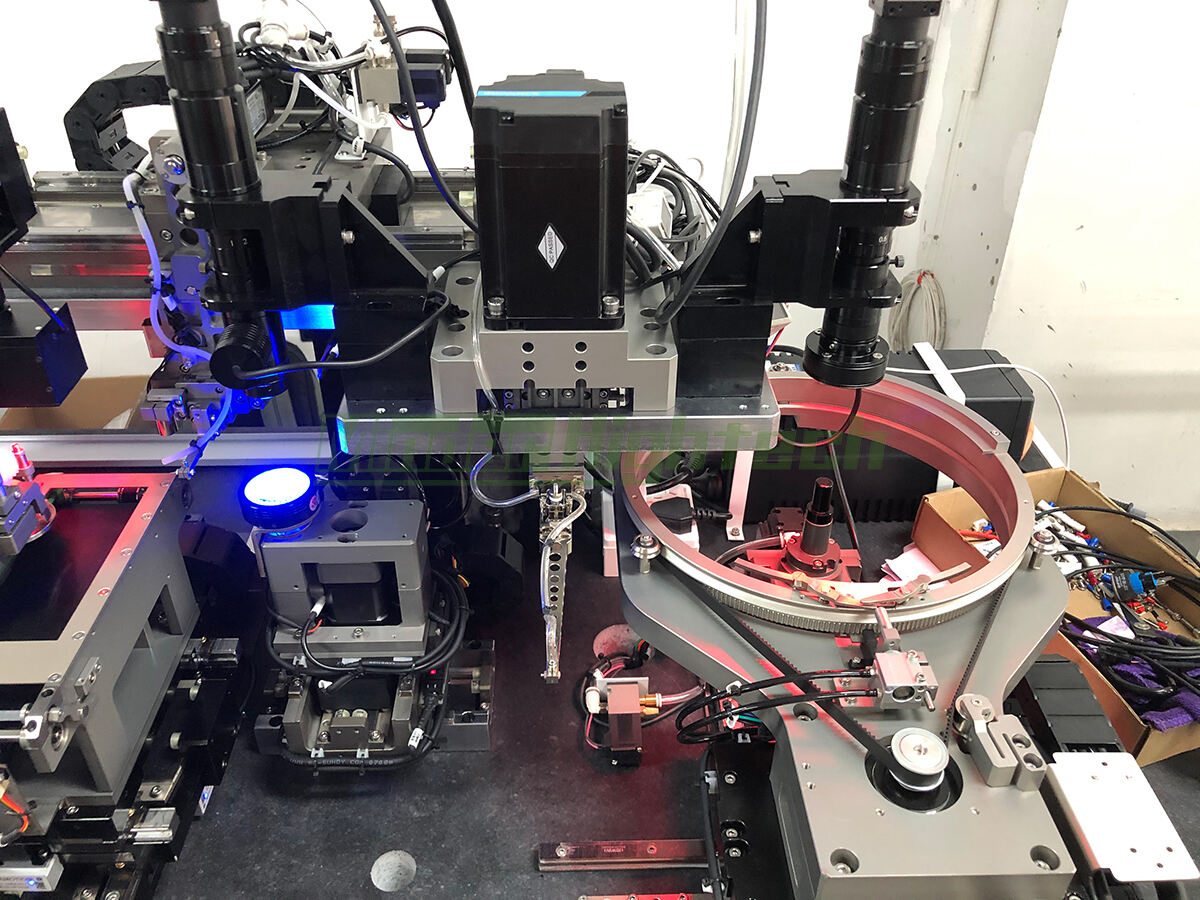

Image recognition system | ||

Method | 256 gray scale | |

Check | ink dot, chipping die, crack die | |

Display screen | 17inch LCD 1024*768 | |

Accuracy | 1.56um-8.93um | |

Optics magnification | 0.7X-4.5X | |

Bonding cycle | 120ms |

Number of program | 100 |

Max die number on one substrate | 1024 |

Die lost check method | vacuum sensor test |

Bonding cycle | 180ms |

Glue dispensing | 1025-0.45mm |

Die lost check method | vacuum sensor test |

Input voltage | 220V |

Air source | min. 6BAR, 70L/min |

Vacuum source | 600mmHG |

Power | 1.8kw |

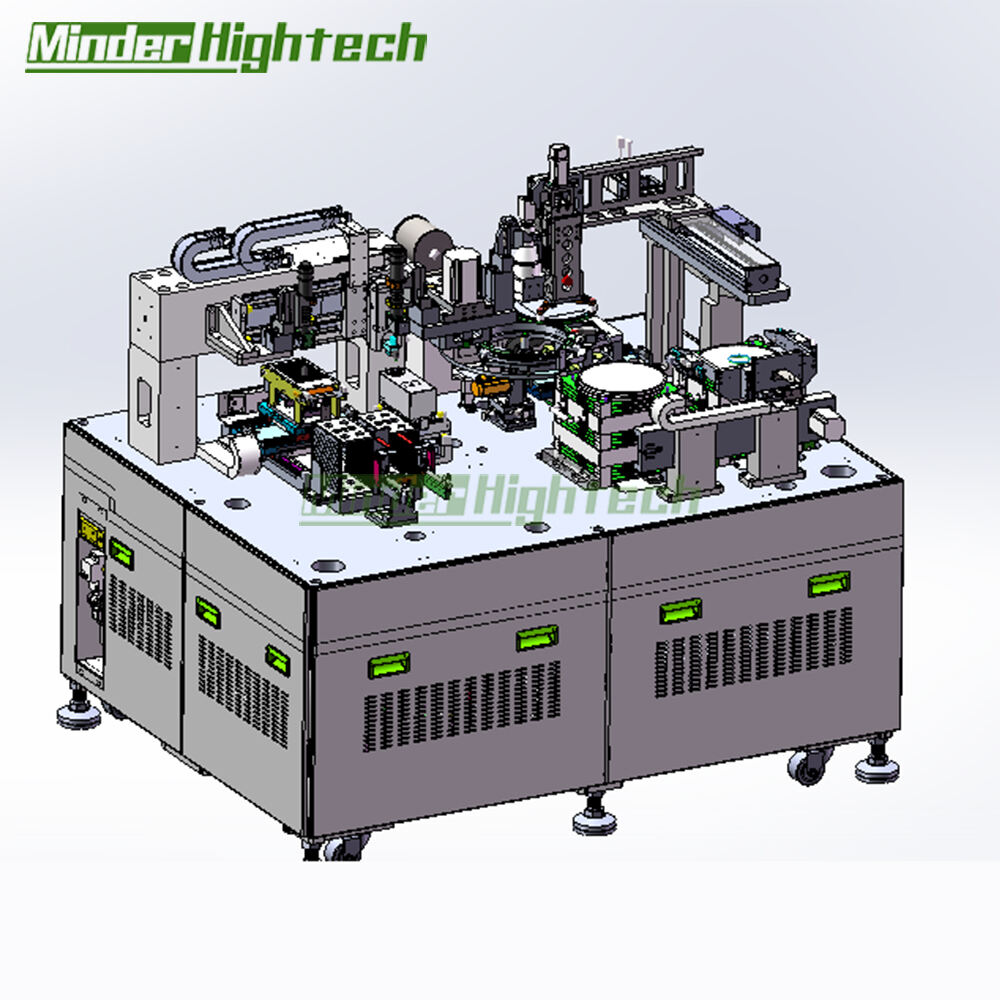

Dimension | 1310*1265*1777mm |

Weight | 680kg |

A: This depends on the quantity. Normally, for the mass production, we need about one week to finish the production.

Minder-Hightech

Introducing the Automatic Die Bonder, the ultimate solution for high-quality and efficient die attaching in LED packaging assembly. Our product is designed to provide precision and consistency in every application, ensuring uniformity and reliability in your LED device production.

With our Automatic Die Bonder, you'll now streamline your manufacturing process and achieve improvements significant efficiency and yield. Our Minder-Hightech

device provides accurate and quick die placement, with a throughput of up to 10, 000 UPH or devices per hour, rendering it an ideal choice for high-volume packaging installation is LED.

Built with advanced features designed to optimize your die attaching process. We have vision is high-resolution that assures precise alignment of the die, guaranteeing accurate and consistent placement each time. Our system additionally provides feedback is real-time allowing you to monitor the entire die attaching process and adjust the machine as needed.

versatile and can accommodate a range is wide of package types and sizes. We can customize the machine to suit the needs of your LED packaging construction process, ensuring that you will get the performance is best and maximum efficiency for your manufacturing line.

Easy task to make use of, by having an interface is user-friendly simplifies operation and eliminates the need for extensive training. Our machine is created with operator safety in mind, with features that prevent accidents and minimize risks during operation.

We simply take pride in the quality of our products and provide excellent after-sales support to ensure your satisfaction is complete with Automatic Die Bonder. Our team of experts is always available to work with you with any questions or concerns, providing prompt and support is reliable you need it.

Invest in the Minder-Hightech Automatic Die Bonder today and experience the benefits of advanced technology in your LED packaging assembly process.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved