Bonding Capability |

48ms/w(2mm Wire Length) |

|

Bonding Speed |

+/-2Ym |

|

Wire Length |

Max 8mm |

|

Wire Diameter |

15-65ym |

|

Wire Type |

Au,Ag,Alloy,CuPd,Cu |

|

Bonding Process |

BSOB/BBOS |

|

Looping Control |

Ultra Low Looping

|

|

Bonding Area |

56*80mm |

|

XY Resolution |

0.1um |

|

Ultrasonic Frequence |

138KHZ |

|

PR accuracy |

+/-0.37um |

|

Applicable Magazine |

||

L |

120-305mm |

|

W |

36-98mm |

|

H |

50-180mm |

|

Pitch |

Min 1.5mm |

|

Applicable Leadframe |

||

L |

100-300mm |

|

W |

28-90mm |

|

T |

0.1-1.3mm |

|

Conversion Time |

||

Different Leadframe |

||

Same Leadframe |

||

Operation Interface |

||

MMI Language |

Chinese, English |

|

Dimension, Weight |

||

Overall Dimension W*D*H |

950*920*1850mm |

|

Weight |

750KG |

|

Facilities |

||

Voltage |

190-240V |

|

Frequency |

50Hz |

|

Compressed Air |

6-8Bar |

|

Air Consumtion |

80L/min |

|

Adaptability |

1-High efficient transducer,more reliable quality ofbond; |

|

2-Table tear and Clamp tear; |

||

3-Sectionalized bonding parameter, for the different interface; |

||

4-Multi sub-program to be combined; |

||

5-SECS/GEM protocol; |

||

Stability |

6-Real time detection of wire deformation; |

|

7-Real time detection of ultrasonic power; |

||

8-Second display screen; |

||

Consistency |

9-Constant loop height,loop length; |

|

10-online BTO for wedge tool calibration by uplook video. |

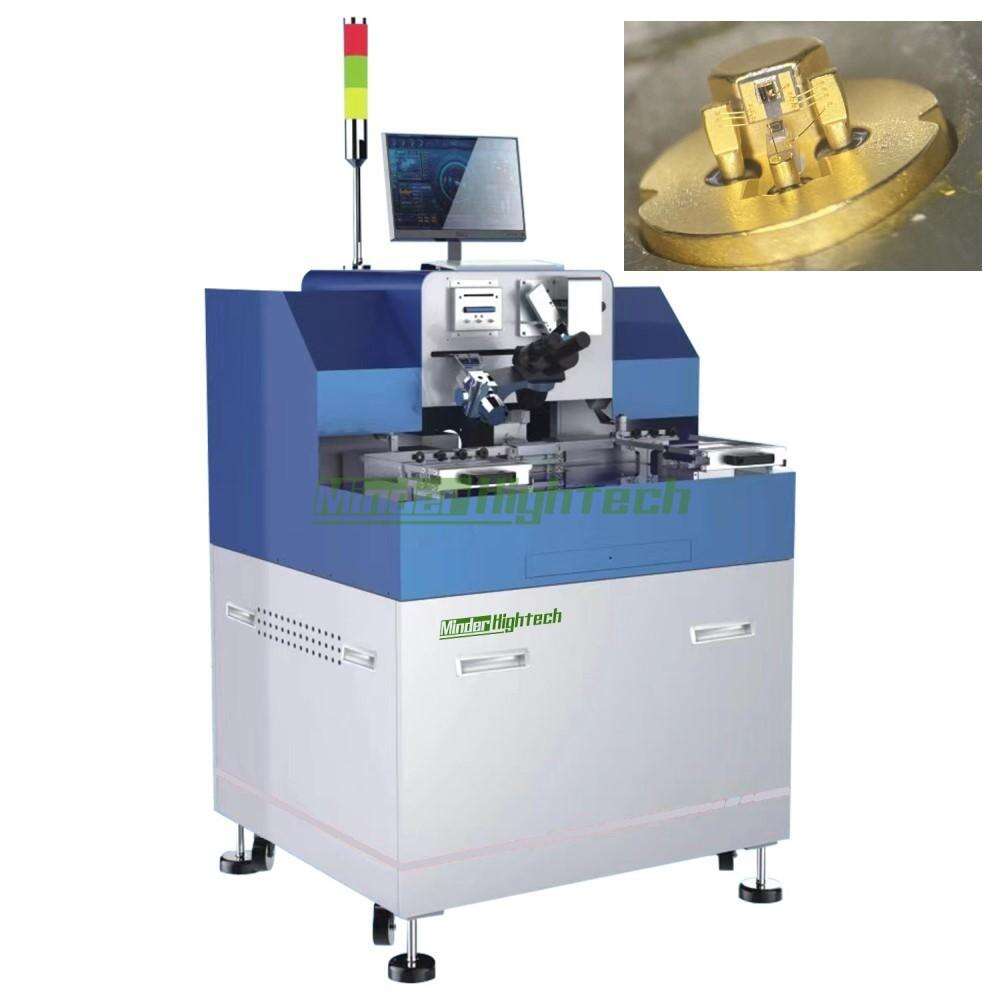

Scope of application |

Discrete devices, microwave components, lasers, optical communication devices, sensors, MEMS, sound meter devices, RF modules, power devices, etc |

|

Welding accuracy |

±3um |

|

Welding line area |

305mm in X direction, 457mm in Y direction, 0~180 ° rotation range |

|

Ultrasonic range |

0~4W control accuracy, ladder flexible application capability |

|

Arc control |

Fully programmable |

|

Cavity depth range |

Maximum 12mm |

|

Bonding force |

0~220g |

|

Cleave length |

16mm、19mm |

|

Type of welding wire |

Gold thread (18um~75um) |

|

Welding line speed |

≥4wires/s |

|

operating system |

Windows |

|

Net weight of equipment |

1.2T |

|

Installation requirements |

||

input voltage |

220V士10%@50/60Hz |

|

Rated power |

2KW |

|

Compressed air requirements |

≥0.35MPa |

|

area covered |

Width 850mm * depth 1450mm *height 1650mm |

|

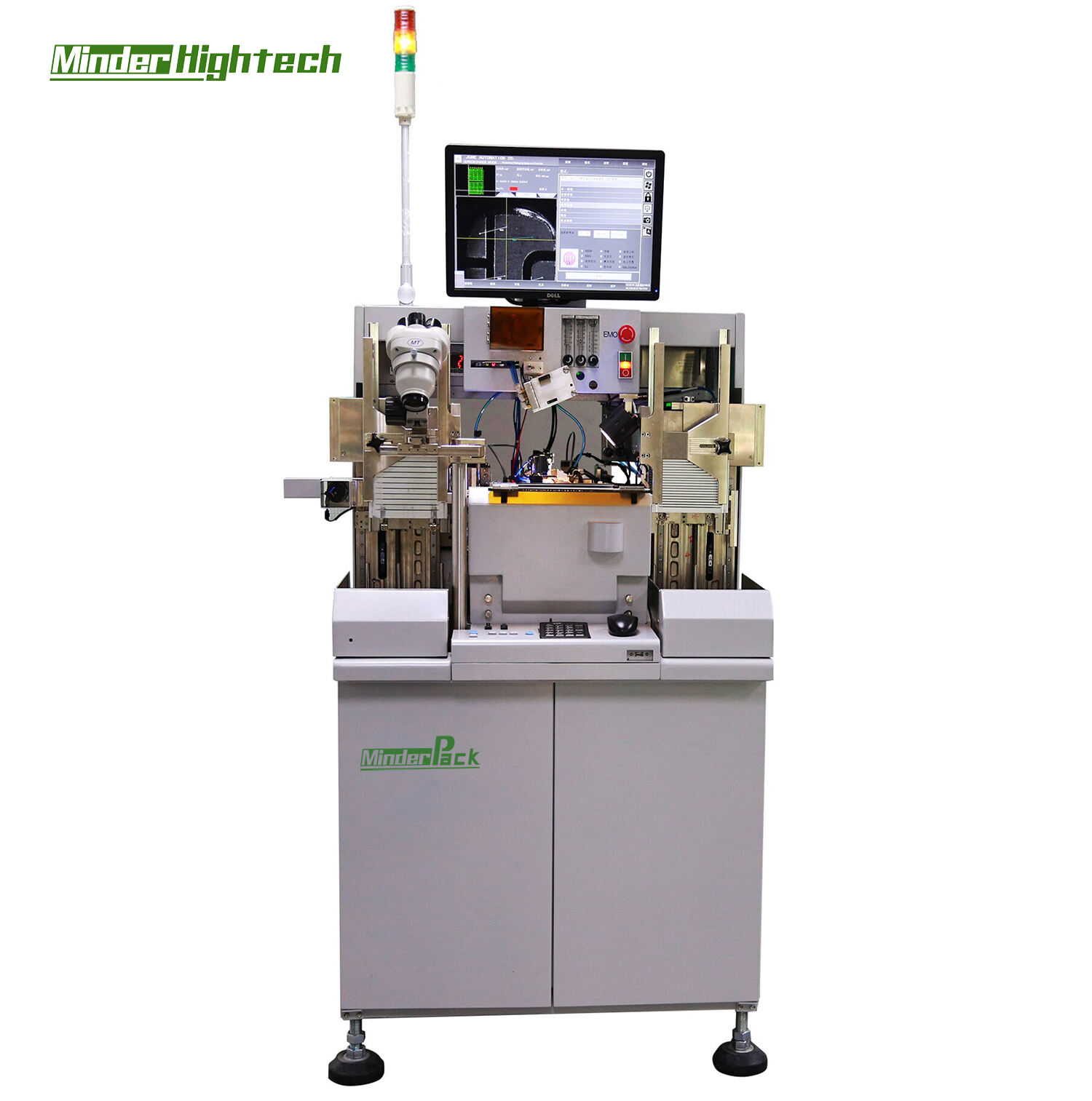

Searching for a high-performing semiconductor machine that can enhance efficiency and reduce mistakes? Look no more compared to the Automatic IC/TO Package Semiconductor Machine coming from Minder-Hightech.

Comprehends the crucial significance of precision and speed in regards to semiconductor wire bonding, which is why they have developed their Automatic IC/TO Package Semiconductor Machine towards wind up being the service is ideal contemporary production demands.

Has the capability towards accomplish constant, reliable bonds in between cable televisions and semiconductor potato chips, decreasing the opportunity of failing and enhancing item life expectancy together with its own progressed wire wedge bonding innovation. This quantity of uniformity is accomplished because of the machine's ingenious command body, which carefully screens and changes essential variables wire is consisting of and loophole advancement, guaranteeing that each and every bond is purely as it should certainly be.

Another include is essential is its own ability towards function effectively and rapidly. This machine is prepared towards manage high-volume manufacturing easily, allowing producers towards enhance their process and stay up to date with require along with an optimum bond speed as high as 10 cables every 2nd. In spite of its own outstanding price, nevertheless, the machine is likewise developed towards be easy to use and user-friendly, possessing a user interface is easy enables drivers towards easily set up and obtain a hold on different specifications as required.

Obviously, dependability is likewise an element is crucial any type of production procedure, while the Automatic IC/TO Package Semiconductor Machine provides on this main likewise. Developed towards be resilient and lasting, along with first-class aspects and building is durable this machine is capable towards endure the roughness of continuous utilize and provide constant efficiency in time.

Whether you are wanting to update your current semiconductor wire bonding abilities or even are beginning a new production procedure from the ground up, the Minder-Hightech Automatic IC/TO Package Semiconductor Machine is the perfect service. Along with its own mix of accuracy, speed, and dependability, this effective machine is certain towards offer the efficiency you have to be successful in today's hectic production atmosphere.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved