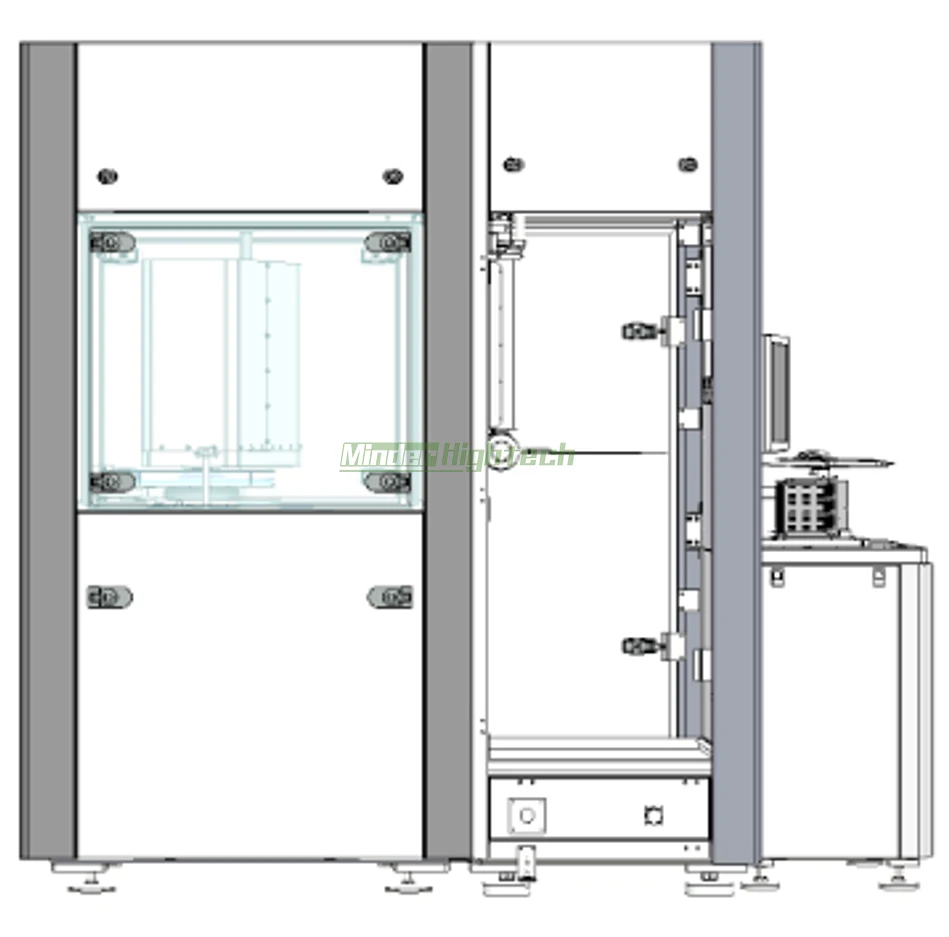

Port |

Quantity * 1, with Q-tank |

|

Robot |

Quantity * 1, for wafer transfer |

|

HCLU |

Quantity * 1, for automatic loading and unloading of wafers |

|

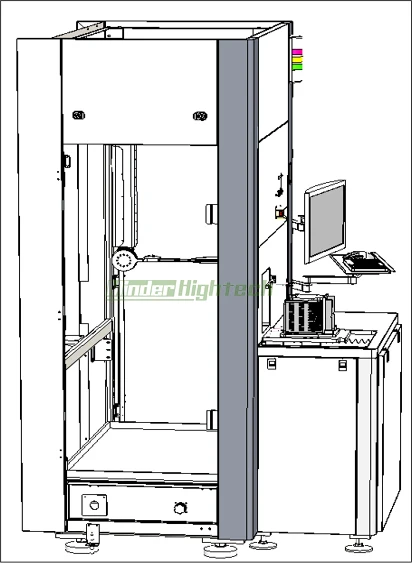

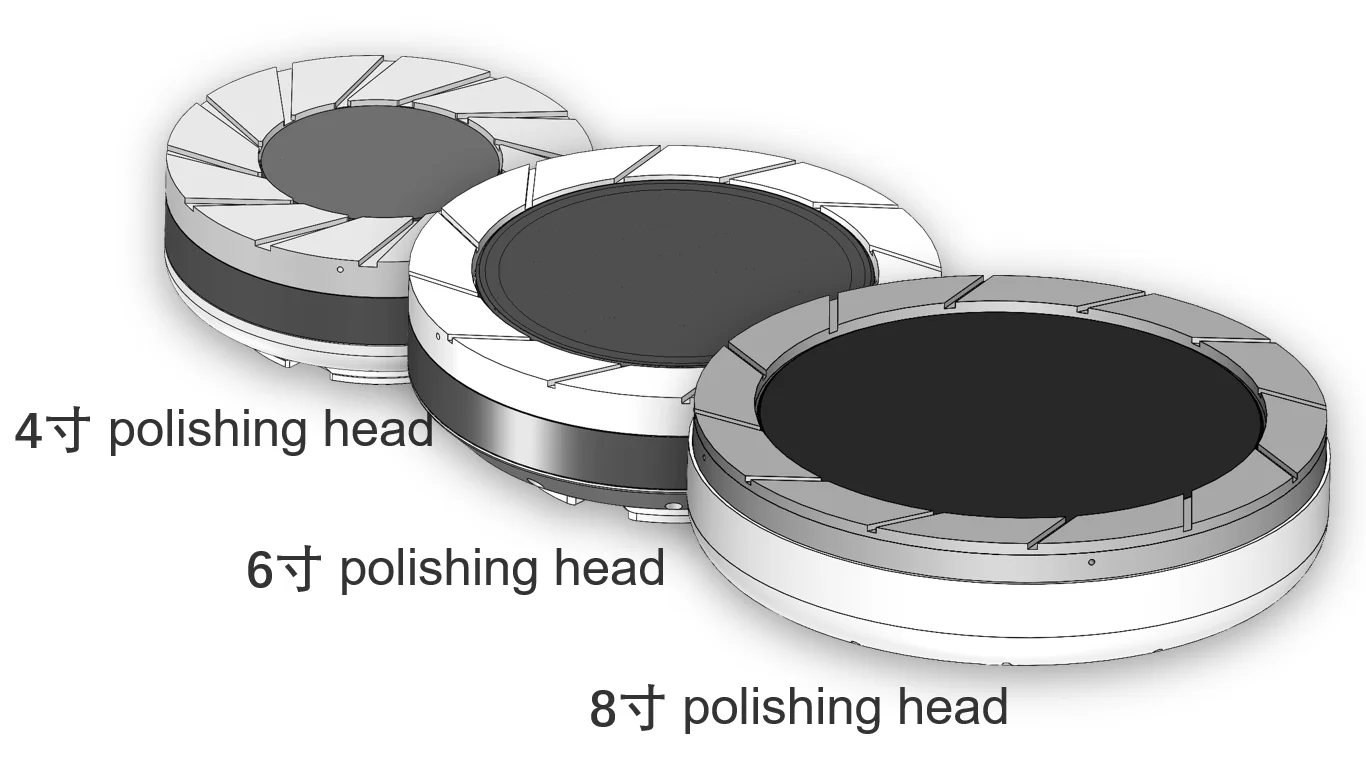

Polishing head |

Quantity * 13 cavity control, control accuracy of 0.1PSI, can support 400-1200 UM wafer operations. |

|

Polishing head speed |

5-150RPM |

|

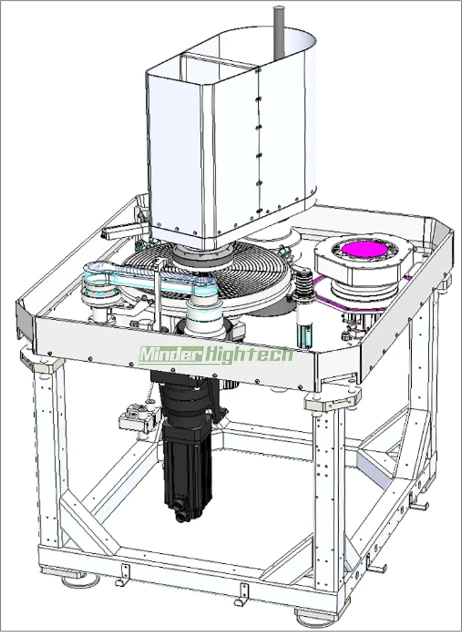

Polishing Disc |

Quantity * 1 Polishing Disc Size 508mm, Polishing Pad Speed 10-150rpm. |

|

Trimming arm |

Quantity * 1 polishing pad. The polishing pad can be polished online (simultaneously) or offline (after polishing). The trimming arm is equipped with a trimming shaft, which can rotate and move up and down, andthe speed and downforce can be controlled. The trimming tool is installed on the trimming shaft and can be quickly removed. According to the different types of polishing pads, different types of dressing tools are configured, including dressing brushes, diamond rings, and diamond discs. |

|

UPA polishing head air pressure control unit |

Quantity * 13Zone adjustable for better surface planarization effect |

|

Polishing liquid supply pump |

Quantity * 2. Peristaltic pumps are used for liquid supply, with 2 peristaltic pumps configured to deliver different polishing liquids to the polishing disc. Each pump can be used in any step of the process. |

|

Slurry Arm |

Quantity * 1 can control the landing point of the slurry and can clean the polishing pad. |

|

The operation control system can achieve user level control, such as operator mode, maintenance mode, and technical mode, and var ious modes are controlled by passwords. The system software can edit the process parameters of each process step and flatten and polish the thin film on the chip surface according to the program. It can monitor the operation status of equipment, monitor process parameters in realtime, andthe software can automatically store various process data. Equipped with an emergency stop button, used to immediately stop equipment operation and cut off control power. |

||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved