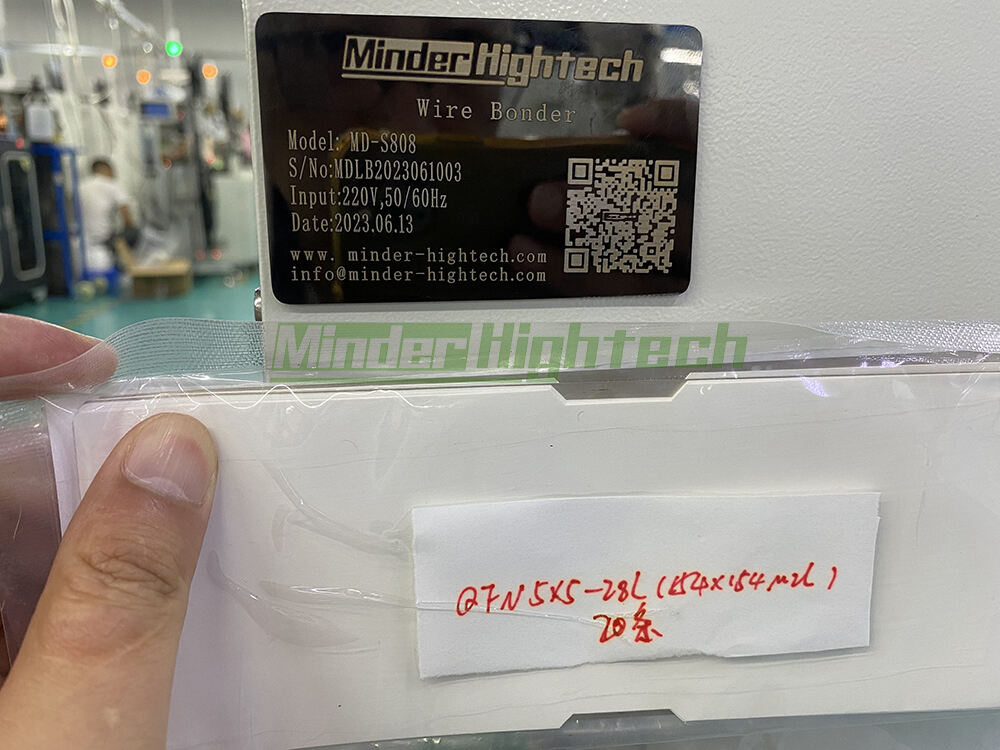

Minder-Hightech

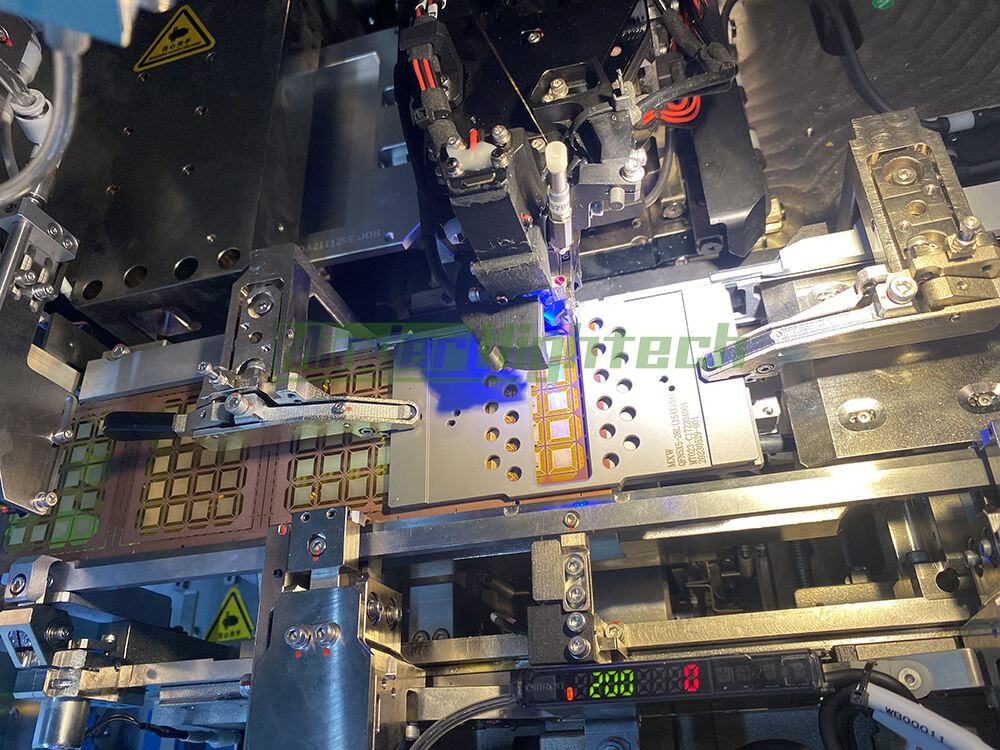

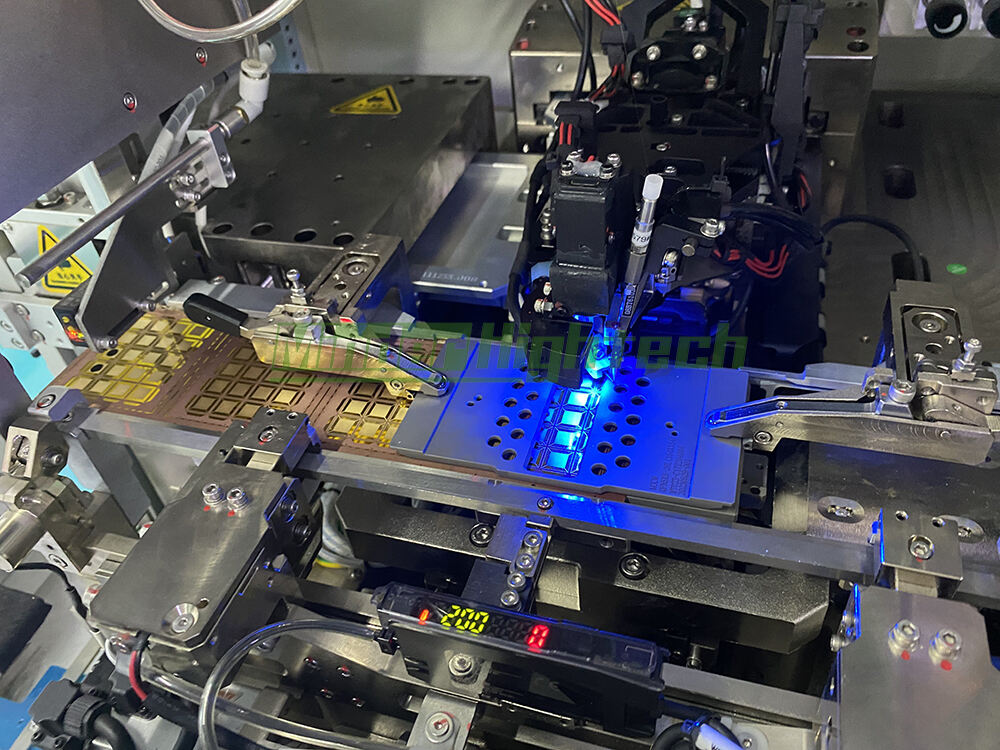

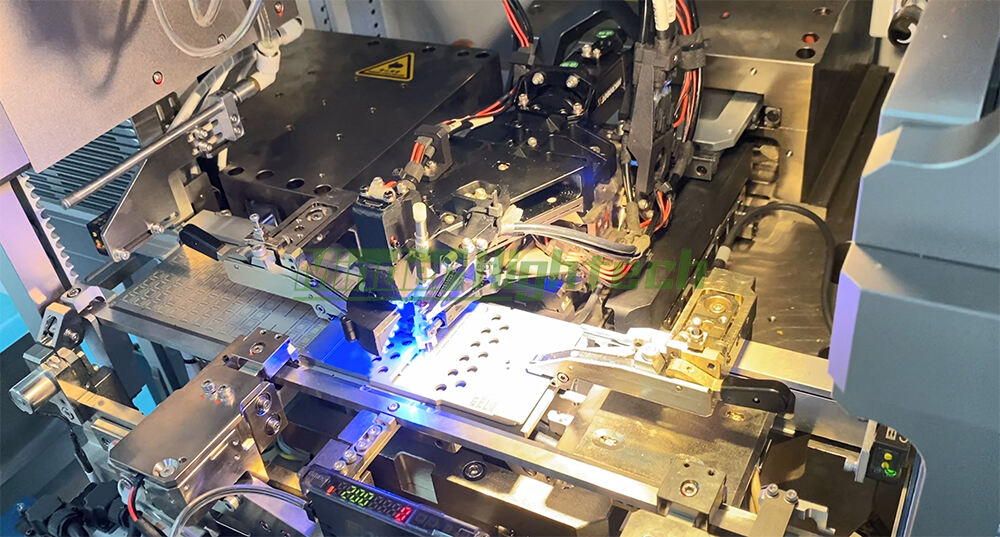

Launching the Big area deep access wedge gold wire bonder wire bonding machine for Semiconductor Packaging LED IC package the solution semiconductor ultimate LED IC packaging.

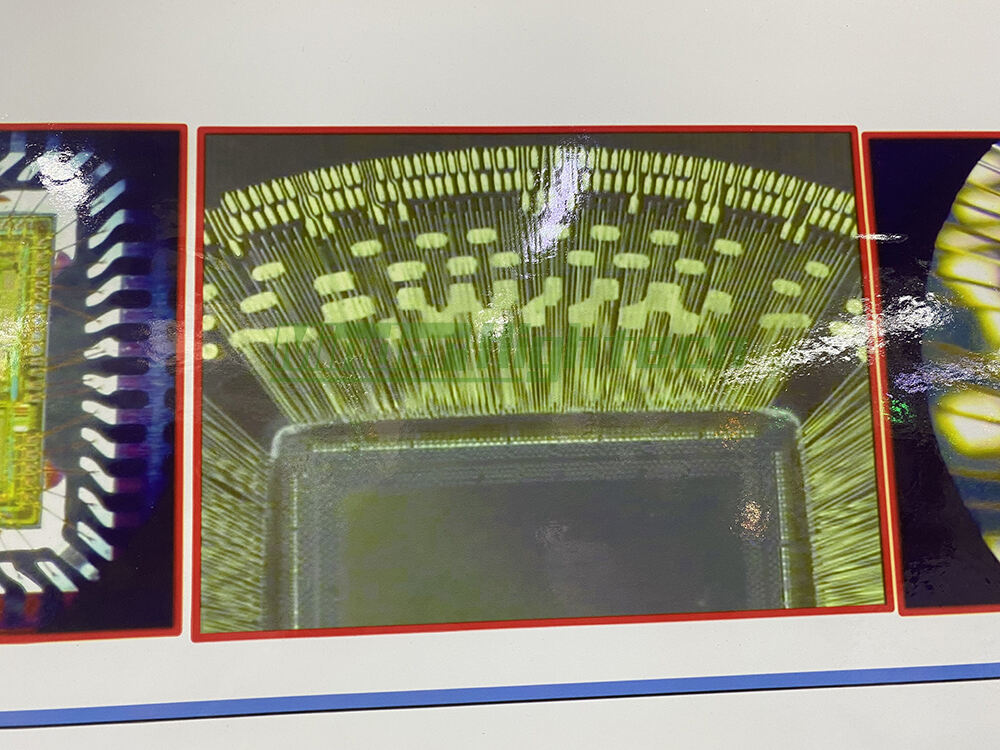

This advanced bonding device is engineered with advanced level features that streamline the production procedure, causing increased effectiveness and manufacturing time paid down. The Minder-Hightech Big area deep access wedge gold wire bonder wire bonding machine for Semiconductor Packaging LED IC package was made having an area big is working enabling deep usage of the bonding website. Thus, giving accuracy cable bonding of Light-emitting Diode IC packages, ensuring constant and gratification dependable.

Furthermore, the bonding device is crafted insurance firms a silver robust feeding procedure that guarantees smooth and uninterrupted procedure through the production procedure.

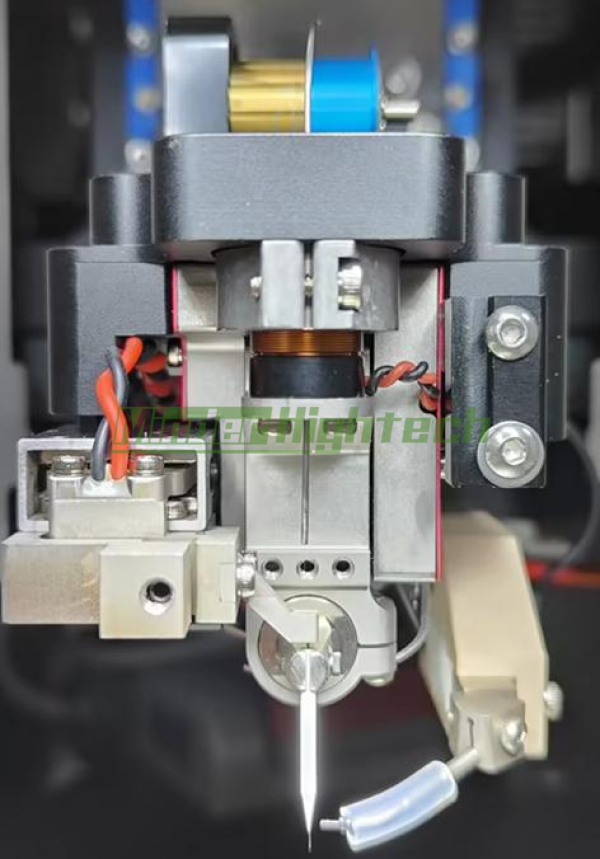

The Big area deep access wedge gold wire bonder wire bonding machine for Semiconductor Packaging LED IC package is a device incredibly versatile can handle many different cable bonding applications. It is perfect for higher level semiconductor packaging and operations, including bonding high-density interconnects and cable bonding for higher level memory packaging. One of the standout highlights of this cable bonding device is its bonding mind high level design. Its engineered having a wedge bonding head that optimizes the bonding procedure, delivering constant, durable, and cable dependable.

Moreover, this bonding device is made by having an adaptive exclusive algorithm that guarantees an increased level of accuracy and quality in to the bonding procedure. This algorithm guarantees cable that works, even in challenging environments, eventually reducing the possibility of manufacturing problems. The Big area deep access wedge gold wire bonder wire bonding machine for Semiconductor Packaging LED IC package is not hard to make use of and maintain.

The program user-friendly simple and easy quick corrections, ensuring performance constant. Furthermore, this cable bonding device is established with durable elements that want minimal upkeep, decreasing downtime and ensuring top performance for the production requirements.

Scope of application |

Discrete devices, microwave components, lasers, optical communication devices, sensors, MEMS, sound meter devices, RF modules, power devices, etc |

|

Welding accuracy |

±3um |

|

Welding line area |

305mm in X direction, 457mm in Y direction, 0~180 ° rotation range |

|

Ultrasonic range |

0~4W control accuracy, ladder flexible application capability |

|

Arc control |

Fully programmable |

|

Cavity depth range |

Maximum 12mm |

|

Bonding force |

0~220g |

|

Cleave length |

16mm、19mm |

|

Type of welding wire |

Gold thread (18um~75um) |

|

Welding line speed |

≥4wires/s |

|

operating system |

Windows |

|

Net weight of equipment |

1.2T |

|

Installation requirements |

||

input voltage |

220V士10%@50/60Hz |

|

Rated power |

2KW |

|

Compressed air requirements |

≥0.35MPa |

|

area covered |

Width 850mm * depth 1450mm *height 1650mm |

|

Scope of application |

discrete devices, microwave components, lasers, optical communication devices, sensors, MEMS, sound meter devices, RF modules, power devices, etc |

Type of welding wire |

gold wire (12.5um-75um) |

Arc length and arc height of welding line |

fully programmable |

Welding wire accuracy |

± 3um, @ 3sigma |

Ultrasonic |

0 ~ 5W control accuracy, step flexible application ability |

Pressure |

0-200g, mechanical resolution 0.1g, force control repeatability |

Suitable cleaver length |

16mm, 19mm |

Welding area |

large area: 330mmx432mm, ± 220 ° rotation range |

Welding wire speed |

3 ~ 7wire / S (@ 25um gold wire & 1mm wire length) |

Operating system |

Windows |

Net weight of equipment |

1350kg |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved