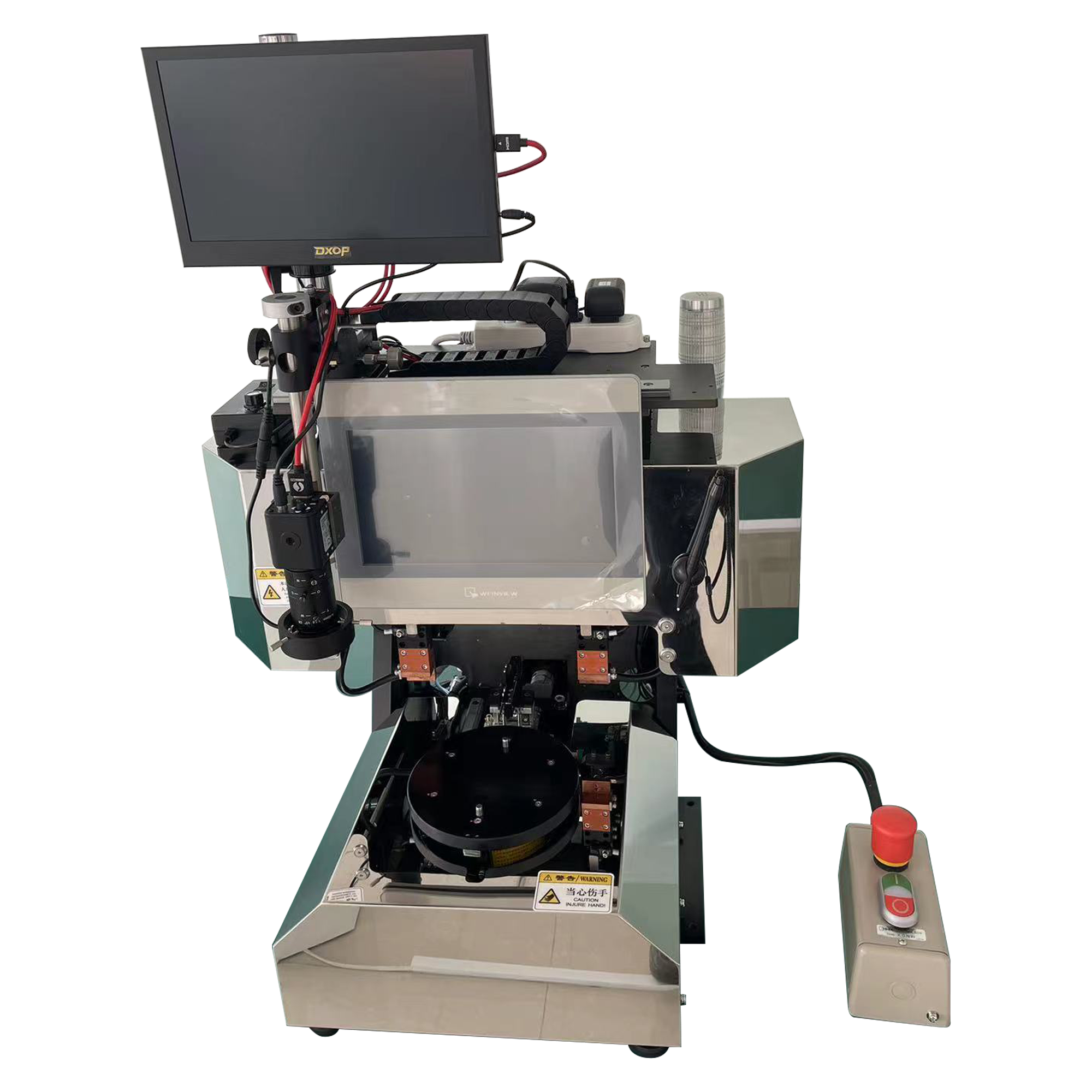

The semi-automatic parallel seam welding machine MCHA-PSW100/200 produced is a shell and cap sealing equipment that integrates a parallel sealing machine and a glove box. Through vacuum baking and operation of the capping process in the glove box, the moisture and oxygen content in the shell can be reduced to meet the needs of high performance and high reliability

This equipment consists of parallel sealing machine and glove box. The sealing machine completes the capping process of the tube shell, and the glove box provides a process environment with low oxygen and low water vapor content for the capping process. The parallel seam welding machine is placed in the operation box of the glove box. After the material is baked in the vacuum oven, it is transferred from the inner door of the operation box to the operation box. After the capping process is completed, it is taken out through the exchange boxMaximum welding power: | 6KW 220V 50/60Hz |

Welding speed: | 0.1mm/s~30mm/s |

Welding pressure: | 0~1500g |

If you are searching for a sealing welder that is developed towards final, have a look at the Minder-Hightech MCHA-PSW100/200. This semi-automatic parallel sealing welder is ideal for requests where you require a solid, dependable secure on your items. Along with its own top-quality building and easy procedure, this welder is perfect for companies that need effectiveness and dependability coming from their devices.

Functions a building is sturdy's developed towards endure the damages of daily utilize. Its own framework is durable is coming from resilient products that withstand rust and corrosion, guaranteeing that the welder will stay real towards the roughness of any type of task site. This will create it a suitable option for production centers, service center, and various other atmospheres where devices dependability is of the significance is utmost.

One connected with standout choices is its own simplicity of utilization. This welder is a simple job towards operate, also for those that have little bit of expertise along with welding devices along with its own semi-automatic style. The setups being user-friendly unobstructed directions guarantee it is simple towards produce and utilize, to obtain to company effectively and rapidly.

Another profit is its own flexibility. This welder will help utilize along with a variety is broad of, consisting of plastics, movies, in addition to various other artificial products. This implies that it might handle a variety of tasks, coming from sealing bags and bags towards welding light-weight items being architectural.

The Minder-Hightech MCHA-PSW100/200 is an outstanding option for companies looking for a top quality semi-automatic parallel sealing welder. Its own resilient buildings, user-friendly manages, and flexible style create it an essential for those that need quality coming from their devices. Therefore, if you are searching for a dependable sealing welder that can assist you obtain the task performed appropriate, look no more compared to the Minder-Hightech MCHA-PSW100/200 - your resources for factory direct sales of high-quality welding devices.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved