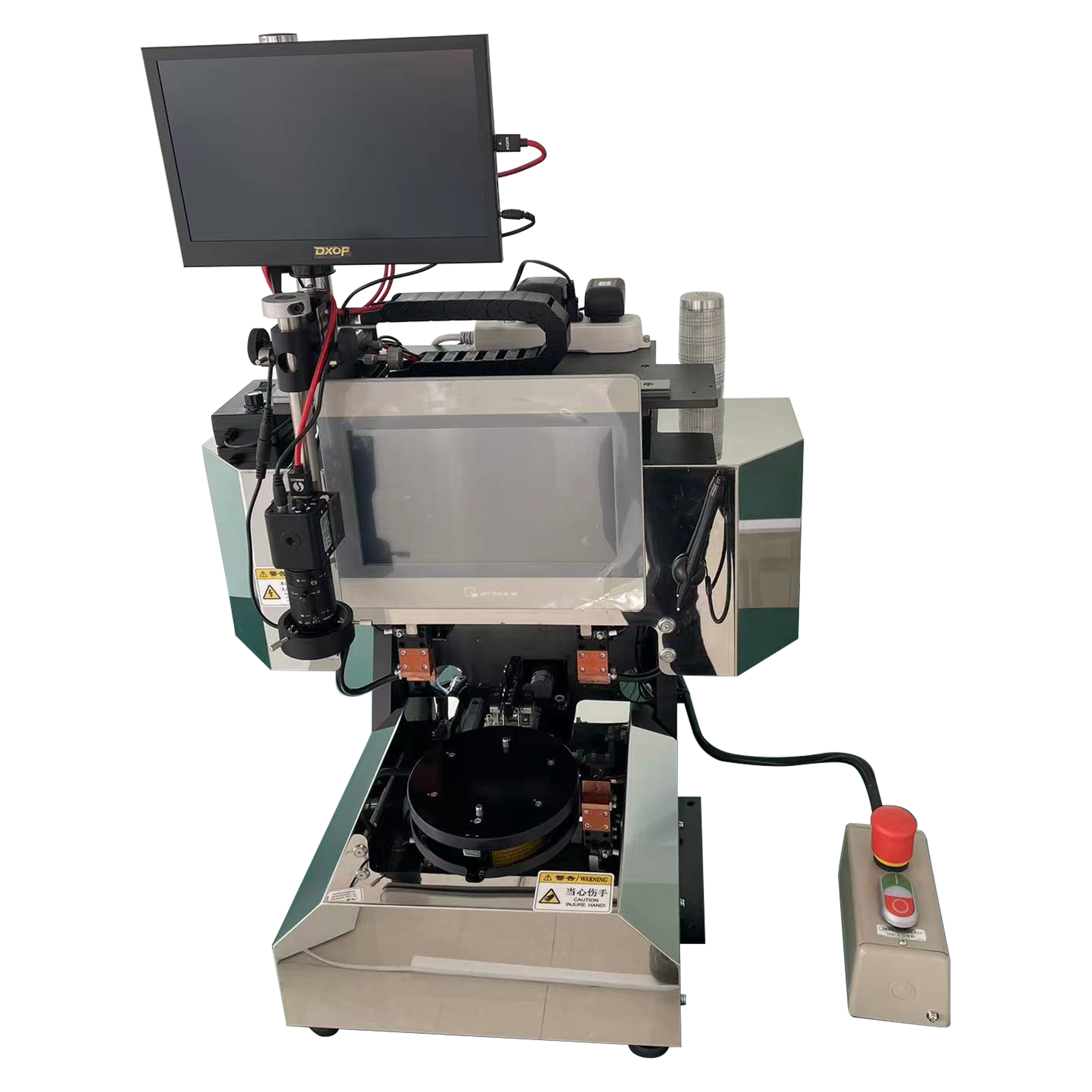

Semi-automatic parallel sealing welder MCHA-PSW100/200

Parallel sealing welder(The contour map)

Equipment Overview

The semi-automatic parallel seam welding machine MCHA-PSW100/200 produced is a shell and cap sealing equipment that integrates a parallel sealing machine and a glove box. Through vacuum baking and operation of the capping process in the glove box, the moisture and oxygen content in the shell can be reduced to meet the needs of high performance and high reliability.

This equipment consists of parallel sealing machine and glove box. The sealing machine completes the capping process of the tube shell, and the glove box provides a process environment with low oxygen and low water vapor content for the capping process. The parallel seam welding machine is placed in the operation box of the glove box. After the material is baked in the vacuum oven, it is transferred from the inner door of the operation box to the operation box. After the capping process is completed, it is taken out through the exchange box.

Features

1) Multiple welding modes: round welding, rectangular welding, regular polygon welding and array welding.

2) The advanced sealing and welding energy control scheme significantly improves the welding quality of the device edge and corner.

3) Accurate control of electrode wheel pressure

4) Very slow welding (for ceramic shell)

5)Cover plate pressing device.

6)Easy management of power parameters

7) Electrode wheel protection function

8) PKG size range:(3×3)mm~(100×100)mm

MCHA-PSW200-200:3X3mm~200X200mm

9) PKG shape:Square, round, regular polygon

Maximum welding power: | 6KW 220V 50/60Hz |

Welding speed: | 0.1mm/s~30mm/s |

Welding pressure: | 0~1500g |

Axis of motion

1、Positioning accuracy of the motion axis:0.02mm

2、Rotation angle range of shell:360°

Welding tightness:

Meets the tightness requirements of GJB548B-2005 "Microelectronics Test Methods and Procedures"

* Glove box technical indicators:

1、Operating cabinet

1.1 Box size:900mm(high)x 750mm(deep)x 1200mm(long)

1.2 gloves: 8-inch glove mouth, 0.4mm thick butyl gloves, hard aluminum alloy glove mouth (after anti-corrosion treatment), caliber 220mm. Number of gloves: 2

1.3 Can maintain a certain positive and negative pressure during use(-12mbar-12mbar)

1.4 Box with automatic air supplement and flushing function, PLC intelligent control pressure

1.5 Integrated humidity detection system (dew point test)

1.6 Integrated oxygen content detection system (oxygen sensor detection)

1.7 Automatic cleaning function: Pressure inside can be set, and the cleaning function is automatically turned on according to the setting requirements

2、Oven and transition chamber

2.2 Oven (inner) size:300mm(high)×300mm(width)×350mm(long)

2.3 Tray: Three-layer work partition and four-layer temperature zone heating

2.4 The PLC can realize the intelligent control of the periodic inflation, pumping and flushing of the heating system, and the supplementary gas comes from the inside of the box

2.5 Heating method: heating plate heating, 3 layers

2.6 Temperature control range: 150℃

2.7 Temperature control accuracy: +/-2℃

2.8 Uniformity of temperature distribution: the temperature distribution difference is controlled at + / 5 ℃

Q: How to buy your products?

A: We have some products in stock, you can take away the products after you arrange the payment ;

If we don’t have the products in stock you want, we will start production once getting the payment.

Q: What’s the warranty for the products?

A: The free warranty is one year from the date of commissioning qualified.

Q: Can we visit your factory?

A: Of course, welcome to visit our factory if you come to China.

Q: How long is the validity of quotation?

A: Generally, our price is valid within one month from the date of quotation. The price will be adjusted appropriately as the price fluctuation of raw material in the market.

Q: What’s the production date after we confirm the order?

A: This depends on the quantity. Normally, for the mass production. we need about one week to finish the production.

Searching for a resilient and dependable sealing welder for your laboratory? Look no more compared to the Minder-Hightech Factory Direct Sales High Quality Semi-automatic parallel sealing welder Vacuum Laboratory Box Machine MCHA-PSW100/200.

High-grade a quantity of progressed features creating it the ideal option for practically any type of laboratory atmosphere. Its own semi-automatic style enables simple treatments, while its own parallel sealing welder guarantees a solid, leak-proof secures each time. And also, its own cleanser sealing abilities enable it towards be perfect for utilized through possessing a selection of different compounds and products.

Exactly just what truly establishes this machine apart is its own quality building. Created coming from top quality products and developed towards final, it is developed towards withstands the needs of hefty utilizes in also the busiest laboratories. And also, along with factory-direct sales offered, you can be guaranteed that you are obtaining the finest costs is feasible quality.

Purchase your Minder-Hightech Factory Direct Sales High Quality Semi-automatic parallel sealing welder Vacuum Laboratory Box Machine MCHA-PSW100/200 today and expertise the distinctions for yourselves.