|

Project

|

Content

|

|

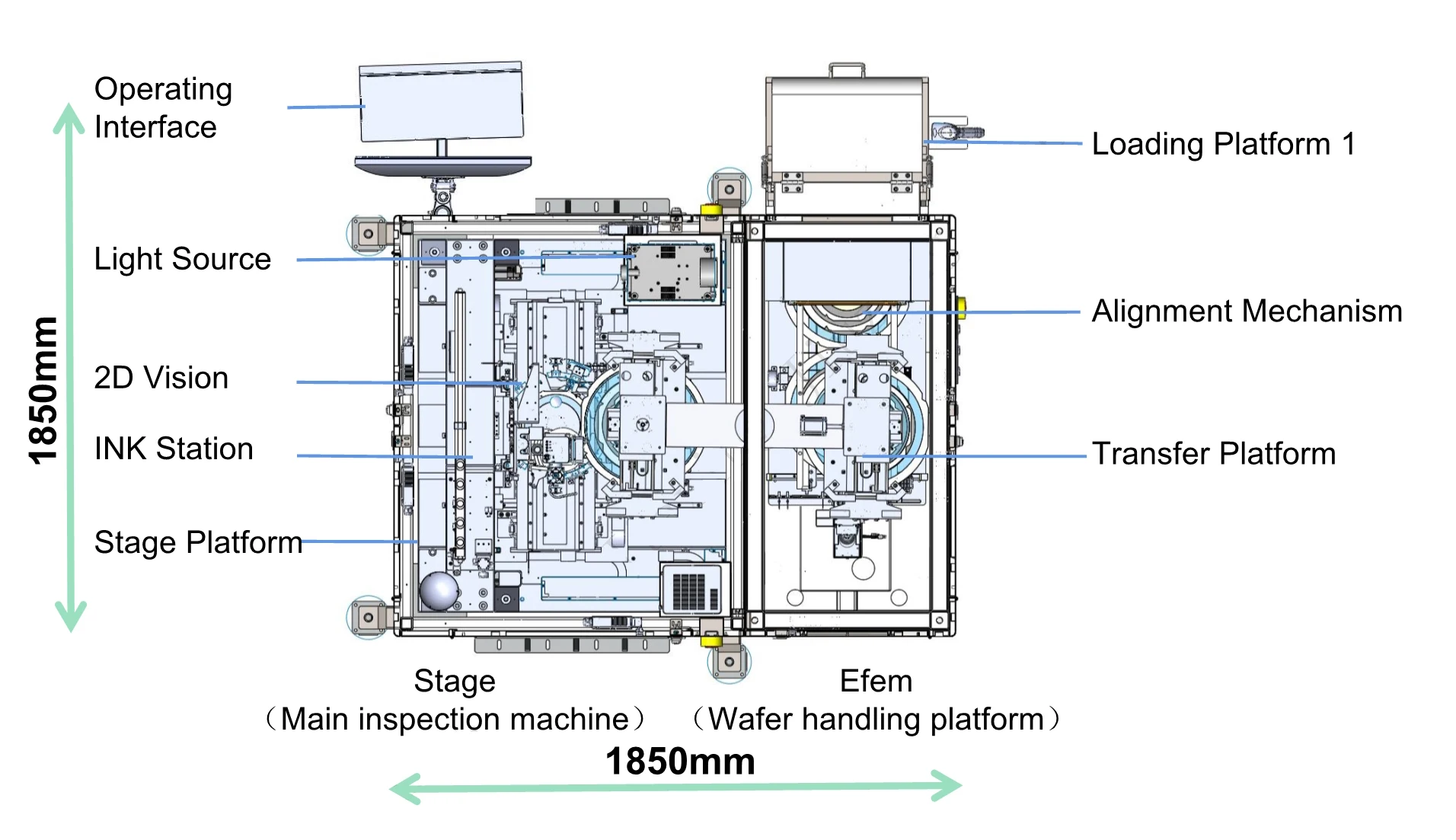

Product Type

|

6", 8", 12" frame wafer

|

|

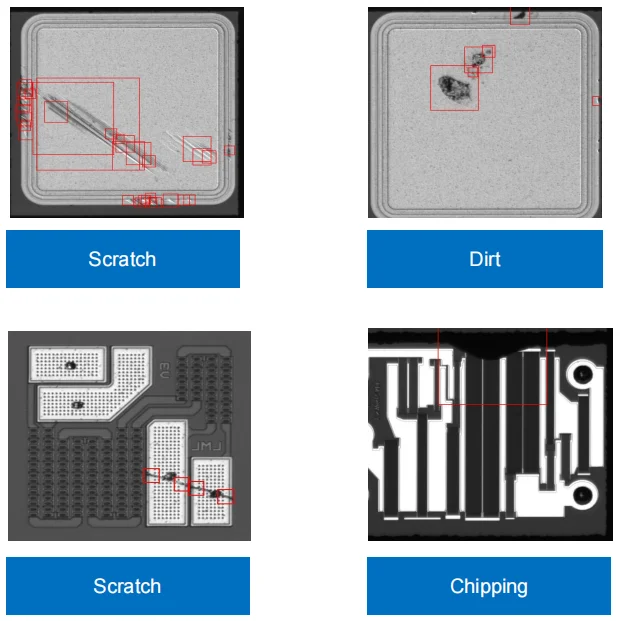

2D Inspection ltems

|

Foreign objects, residual glue, particles, scratches, cracks, contamination, CP deviation, excessive area, etc

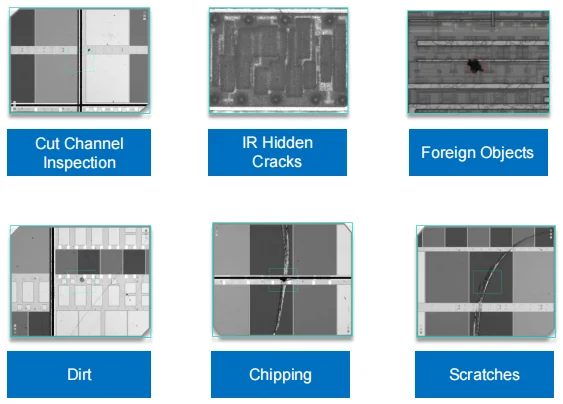

Cutting channel deviation and chipping |

|

Cutting Path Inspection Items

|

6", 8", 12" frame cassetee

|

|

Lens and Resolution

|

2x(2.75um)/3.5x(1.57um)/

5x(1.1um)/7.5x(0.73um)/10x(0.55um) |

|

Precision

|

0.55μm/pixel

|

|

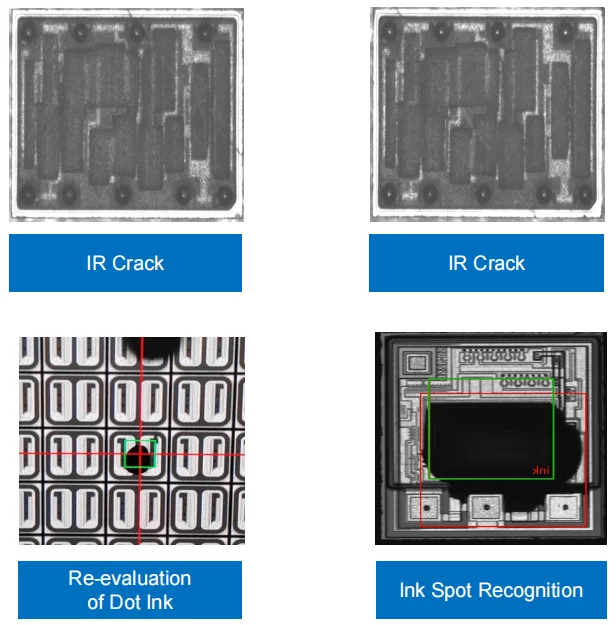

Optional and Customized

|

INK module, IR module

|

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved