|

Category

|

Project

|

MD-E24L

|

MD-E30L

|

MD-E40L

|

MD-E60L

|

MD-E80L/XL

|

MD-E100L/XL

|

|||||

|

Film size

|

Width of double roll material(mm)

|

4.5-12

|

6-16

|

9-22

|

14-30

|

19-40

|

21-50

|

|||||

|

Width of single roll material (optional)(mm)

|

/

|

/

|

/

|

/

|

80

|

100

|

||||||

|

Thickness of Metal Film Material(μm)

|

1.2-10

|

2.5-10

|

2.5-10

|

3-10

|

3.5-10

|

3.5-10

|

||||||

|

Inner/Outer Diameter of Metal Film(mm)

|

75/180

|

75/210

|

75/240

|

75/260

|

||||||||

|

Aluminum foil thickness(μm)

|

15-20

|

|||||||||||

|

Aluminum foil width(mm)

|

30

|

35

|

50

|

70

|

90

|

110

|

||||||

|

Inner/Outer Diameter of Aluminum Foil(mm)

|

40/160

|

|||||||||||

|

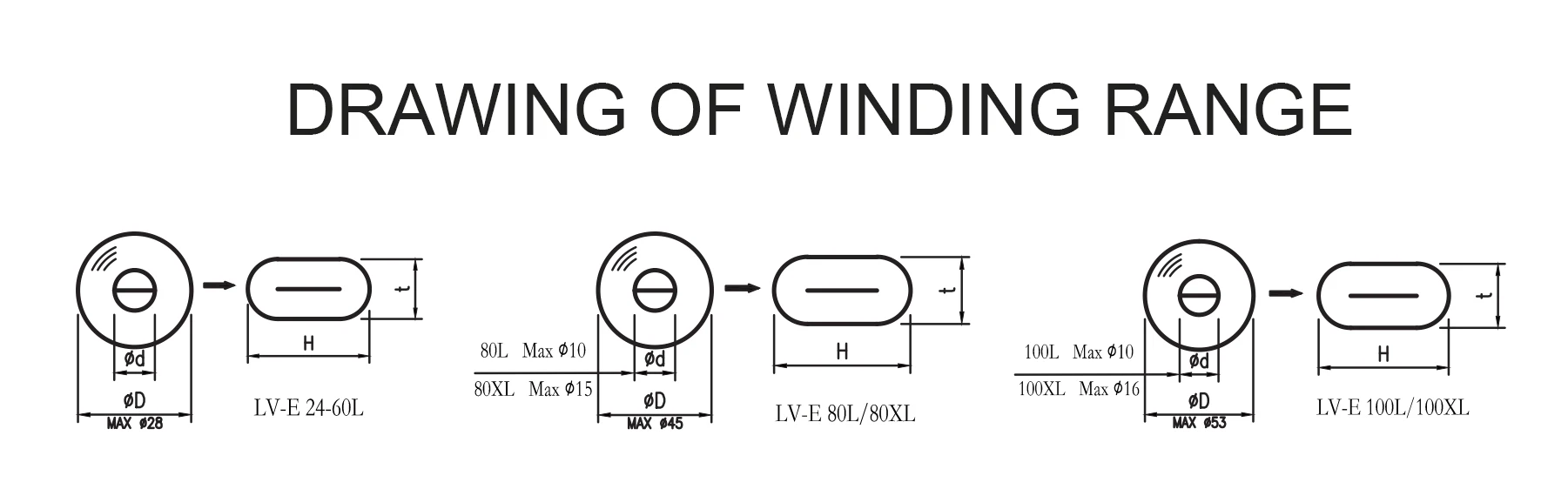

Elements size

|

Standard mandrels diameter(mm)

|

1.5,2,2.5,3

|

2,2.5,3,4

|

2.5,3,4,5

|

3,4,5,6

|

4,5,6,8

|

5,6,8,10

|

|||||

|

The range of mandrels(mm)

|

1.2-5

|

2-5

|

2.5-6

|

3-8

|

4-10/4-15

|

5-10/5-16

|

||||||

|

Maximum diameter of elements(mm)

|

28

|

45

|

53

|

|||||||||

|

Basic parameters of equipment

|

Material hanging shaft(pc)

|

4

|

||||||||||

|

Maximum speed of main volume(rpm)

|

10000

|

9000

|

7500

|

6500

|

||||||||

|

Tension range(g)

|

20-120

|

20-120

|

30-180

|

50-400

|

50-600

|

50-800

|

||||||

|

Pressure range(g)

|

0-480

|

0-960

|

||||||||||

|

Equipment dimensions (L x W xH)(mm)

|

1300x830x1540

|

|||||||||||

|

Net weight of equipment(kg)

|

500-900

|

|||||||||||

|

Gas source(Mpa)

|

0.5-0.6

|

|||||||||||

|

Power Supply

|

AC 220V ±10% 50Hz 1.5Kw-1.8Kw

|

|||||||||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved