|

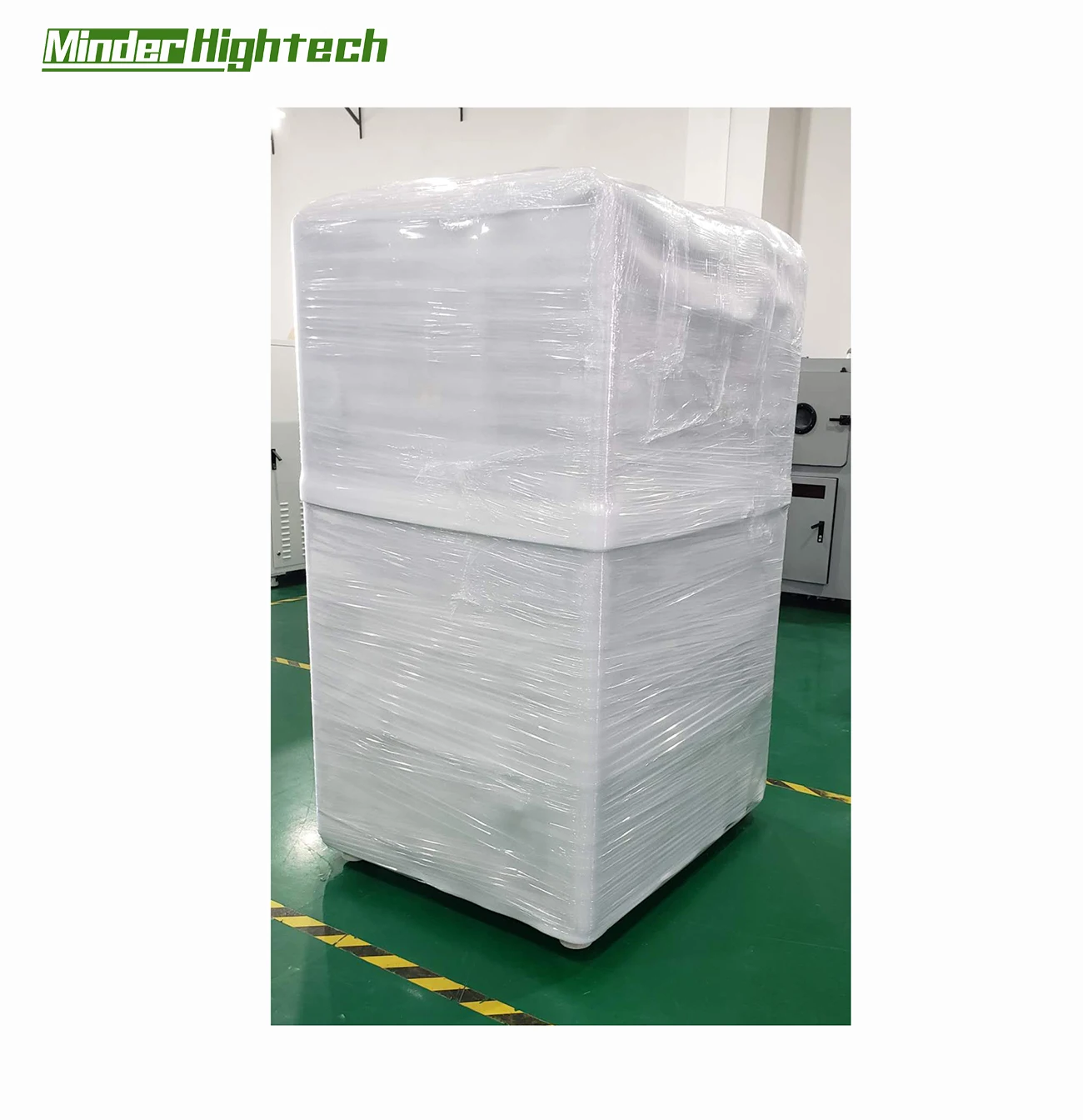

Vacuum plasma host unit (60)

|

||||

|

Equipment size

|

L 950×W 900×H 1650mm

|

|||

|

weight

|

350Kg

|

|||

|

Demand power supply

|

AC380V, 50 / 60Hz, 5 line, 16A (total open type above C)

|

|||

|

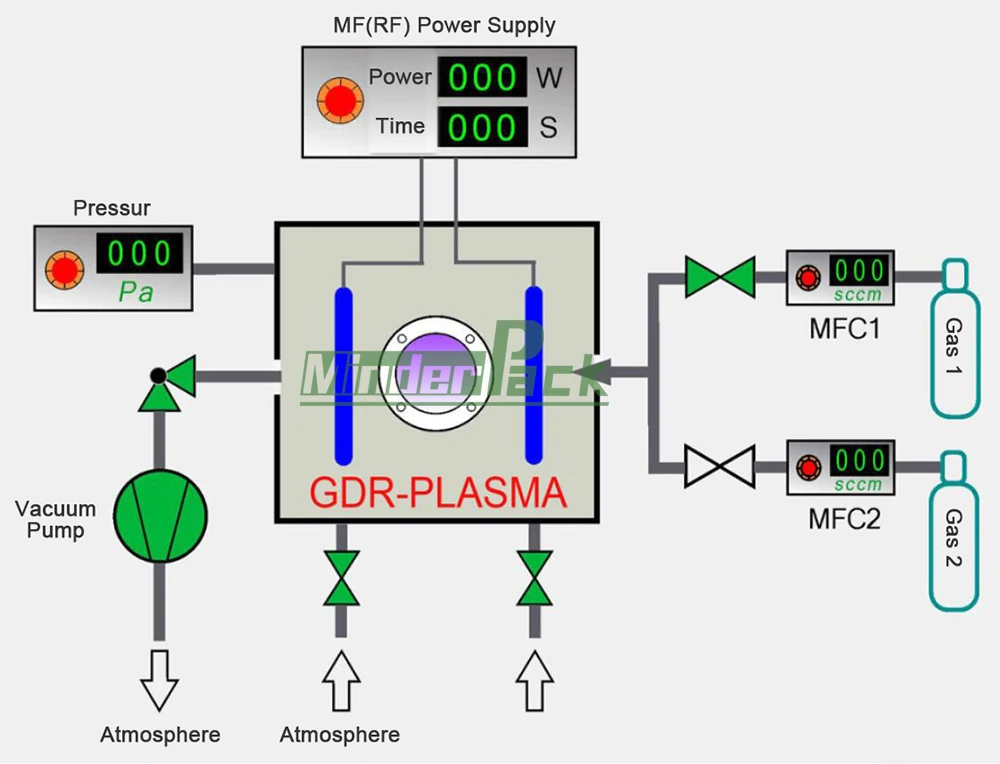

Plasma generator specification

|

||||

|

power

|

radio frequency

|

intermediate frequency

|

||

|

0~600W

|

0-1000W

|

|||

|

supply frequency

|

13.56MHz

|

40 K Hz

|

||

|

Vacuum system

|

||||

|

vacuum pump

|

Double-stage rotary pump (oil pump): 40m3/h

|

|||

|

vacuum pipeline

|

All stainless steel line, as well as high strength vacuum bellows

|

|||

|

material quality

|

Aluminum alloy (customizable stainless steel cavity)

|

|||

|

thickness

|

25mm

|

|||

|

tightness

|

Military-grade welding seal

|

|||

|

Internal dimensions of the cavity

|

375*375*430mm(Width* high * depth)

|

|||

|

Electric plate effective size

|

247*281mm (wide* depth)

|

|||

|

Available space spacing

|

22mm

|

|||

|

Electroplate arrangement

|

Horizontal layout, can be active extraction

|

|||

|

trays

|

Standard set, material optional (aluminum, steel wire mesh)

|

|||

|

work space

|

6 layer

|

|||

|

process gas

|

||||

|

Flow range

|

0~300SCCM

|

|||

|

Process gas gas route

|

Standard with two ways, can be customized. The process gas pipeline is made of ferrofllon

|

|||

|

navar

|

||||

|

SC

|

PLC

|

|||

|

interactive mode

|

7-Inch touch screen

|

|||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved