1. With A scan, B scan, C scan, multi-layer scanning, tray scanning, thickness measurement and other series of scanning modes.

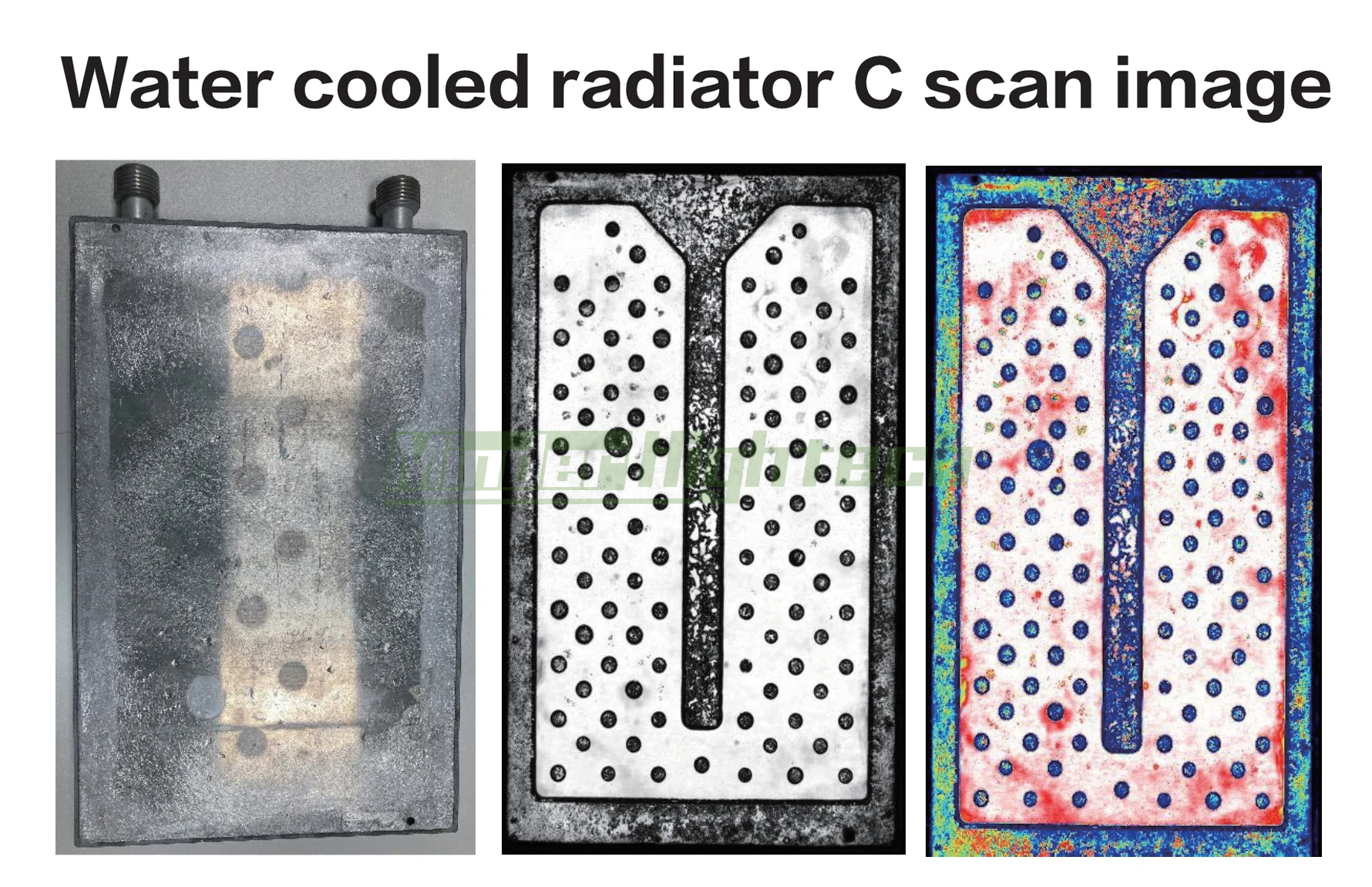

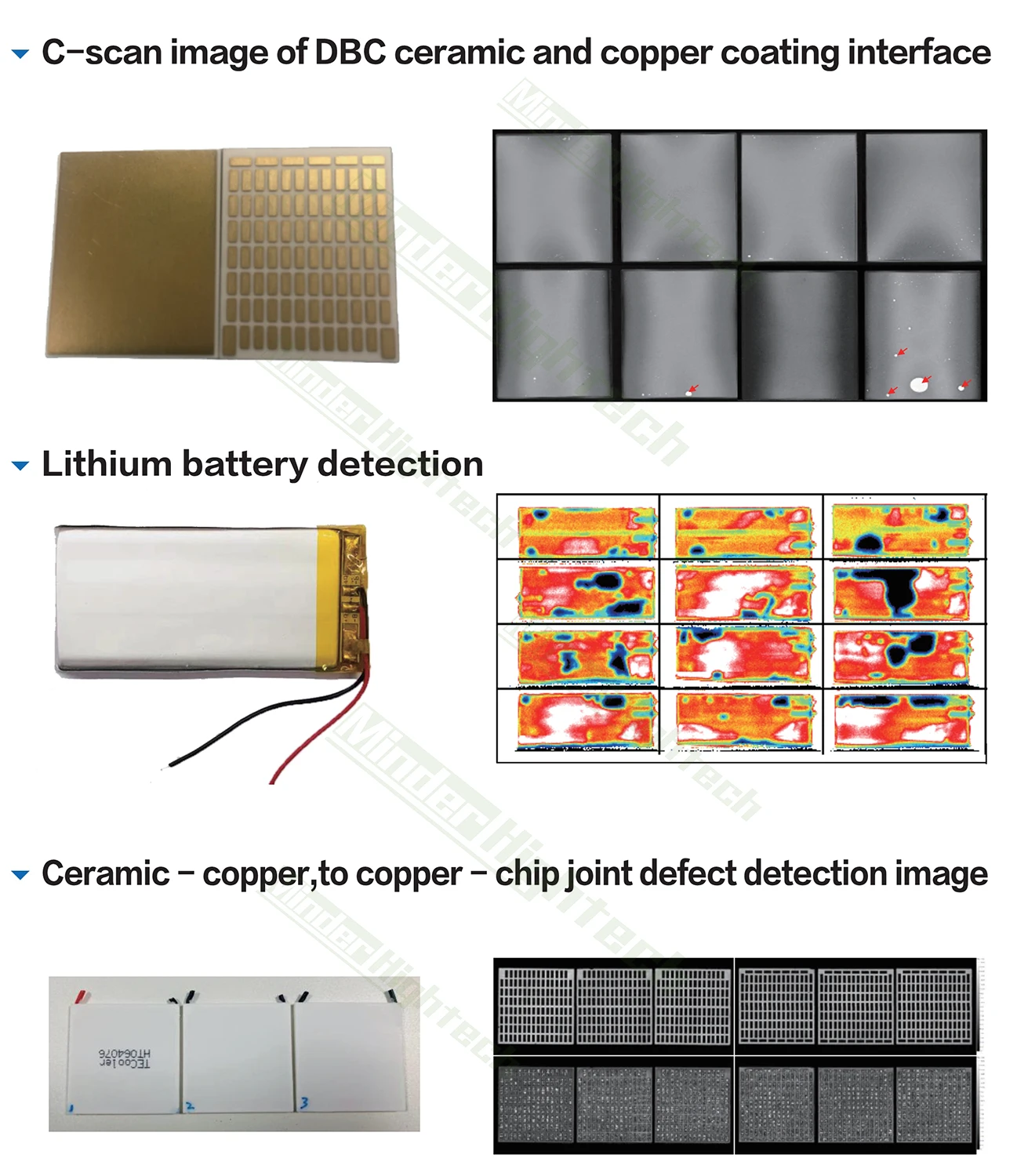

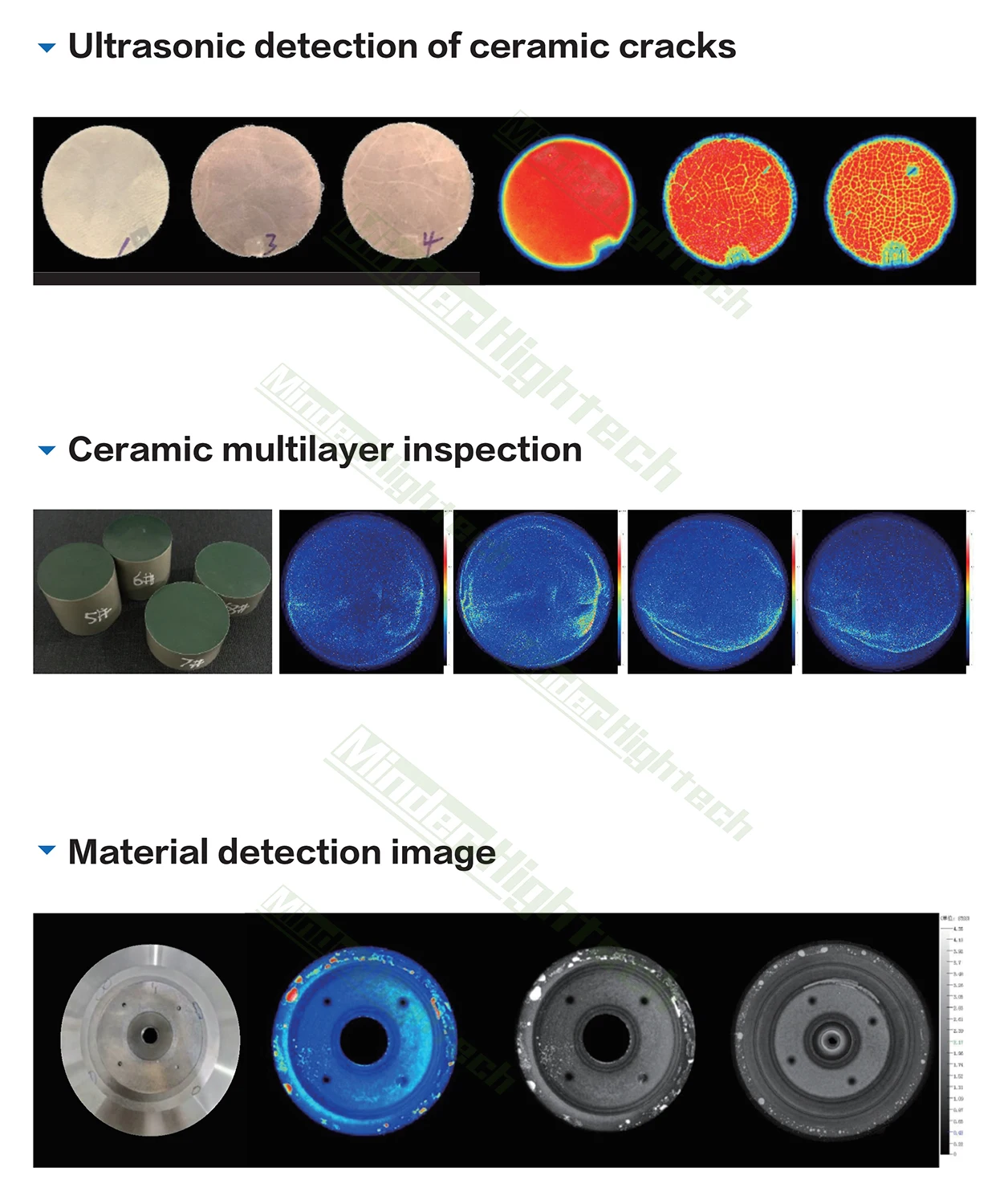

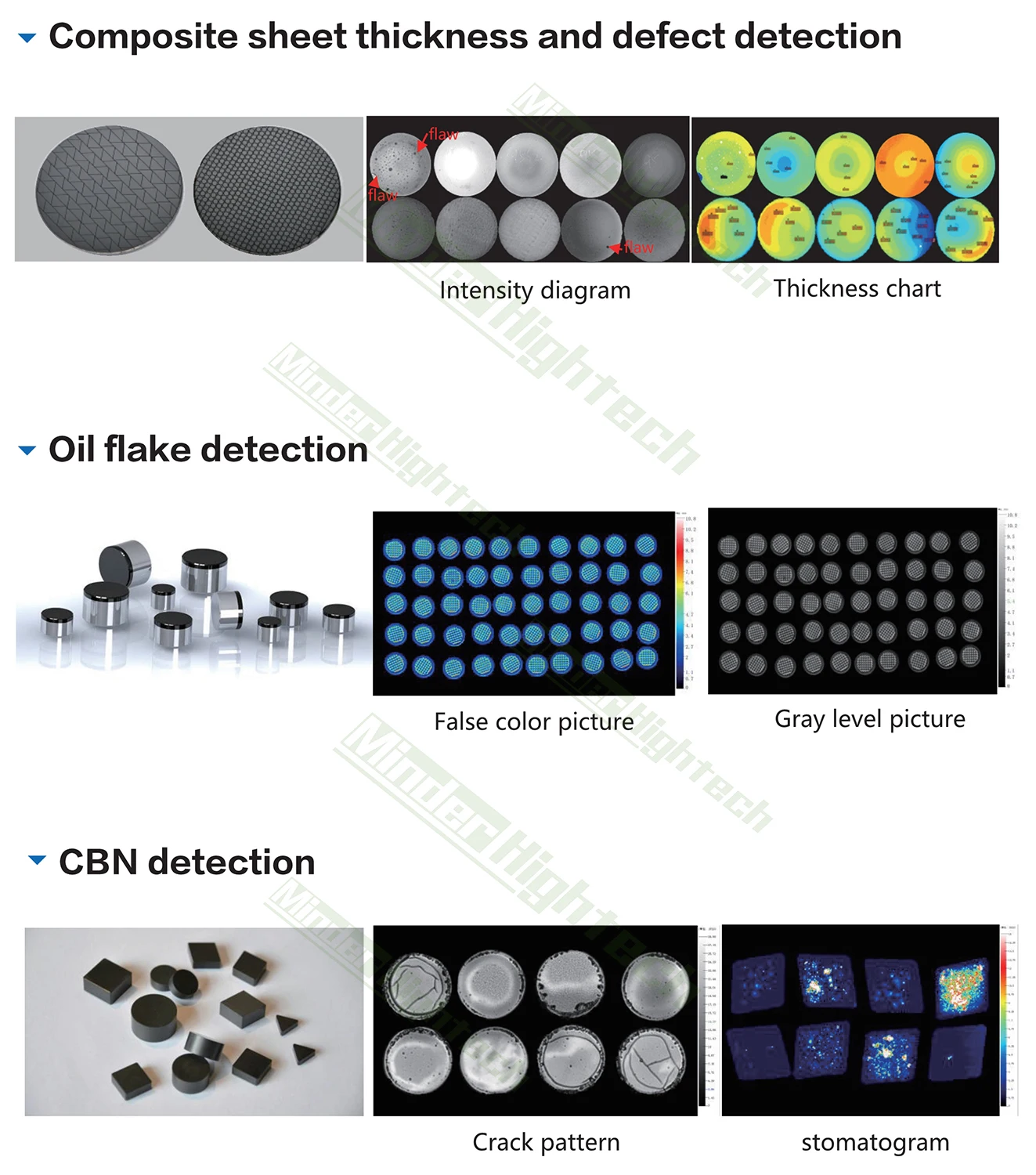

2. With quantitative measurement and analysis function, visually display the position, shape and size of the internal defects of the tested parts in the form of images, and cay out the size and area statistics of the detects, and automatically

calculate the percentage of defects in the measured area; With defect size identification: Thickness and ranging functions.

3. With image coloring function, can automatically color according to phase reversal; Manual coloring according to gray level: Automatic coloring according to thickness changes.

4. Suitable for the rapid scanning analysis of a single device, can also be placed in batches of samples synchronous defect identification quickly screen out unqualified products.

5. Compatible with 1-230MHz ultrasonic probe.

6. Testing software independent research and development, English and Chinese interface, can be continuously upgraded according to customer needs.

7. Can be adapted to double probes according to needs. improve detection efficiency

8. Can be upgraded to dual-channel configuration, efficiency doubled

9. According to the specific test samples and needs of customers, we can provide software and fixture custom development.

10. According to customer needs, develop Al intelligent interpretation algorithm to improve product defect identification

ability.