|

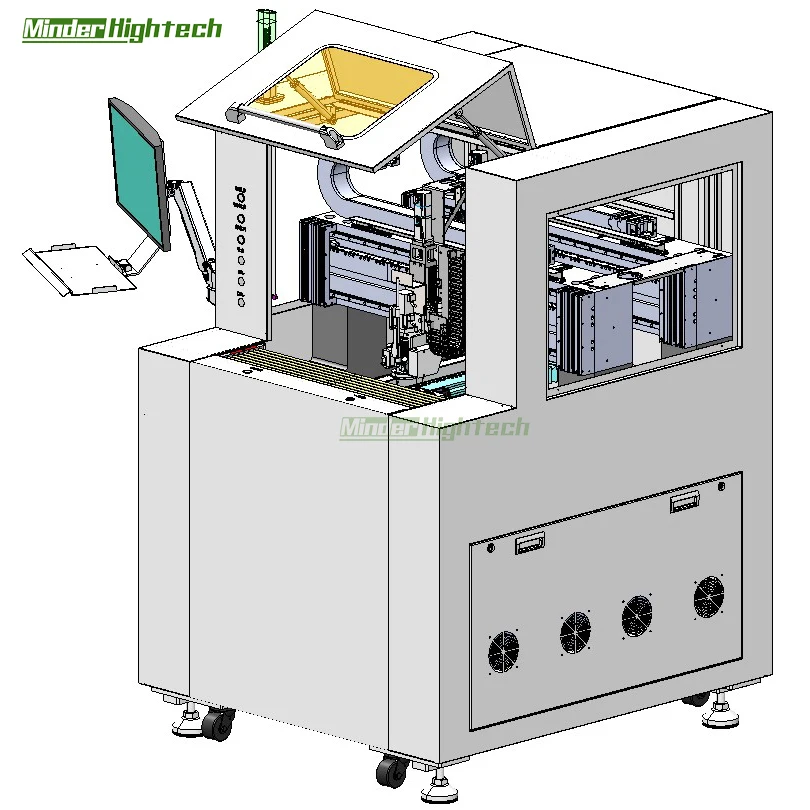

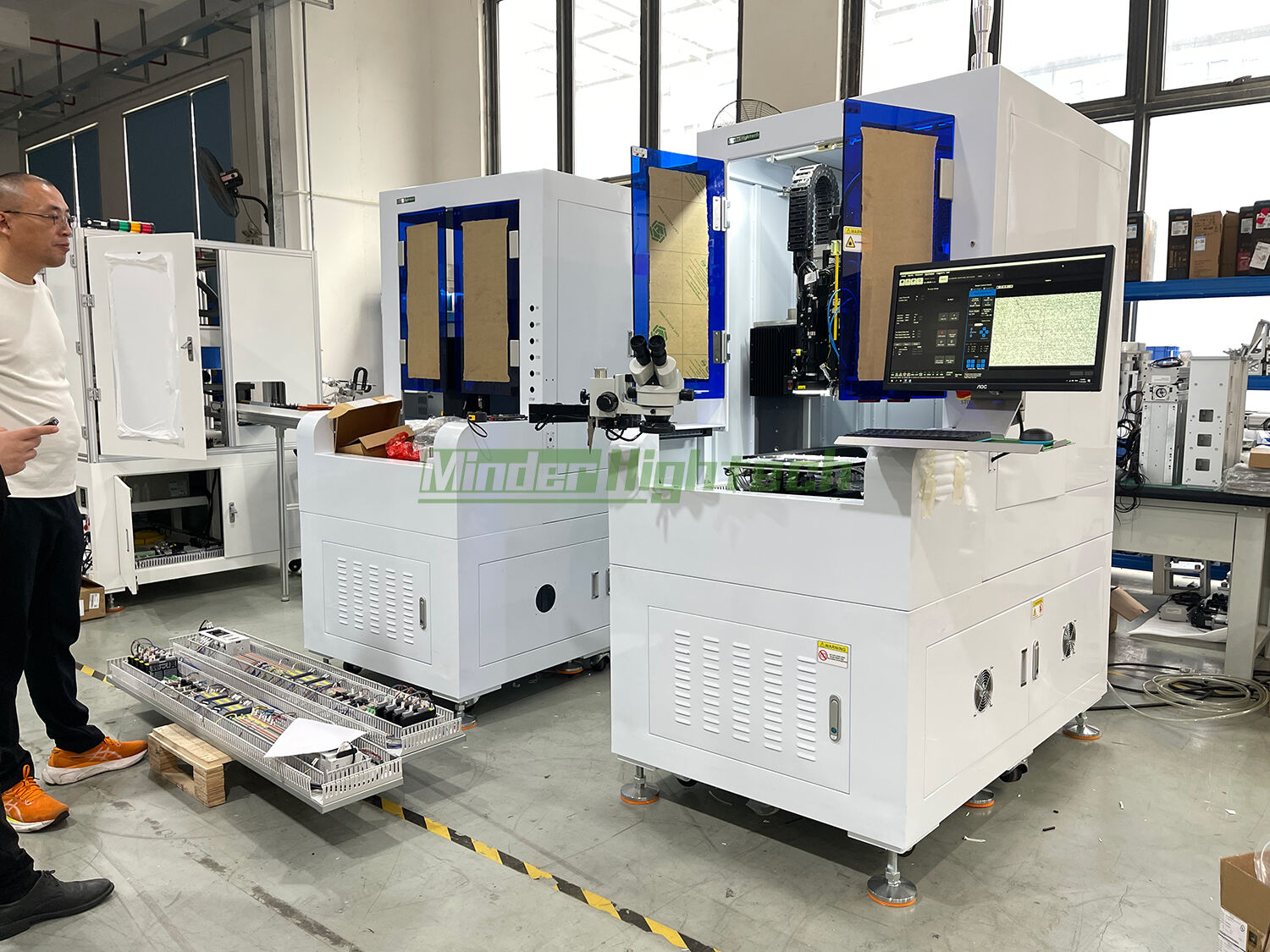

Model number

|

MDZC-LBP500

|

MDZC-LBP1000

|

MDZC-LBP7076

|

||

|

Laser power

|

20w or 50w

|

100w

|

20w+100w(dual)

|

||

|

Laser wavelength

|

1064nm

|

||||

|

Cooling method

|

Full air cooling

|

||||

|

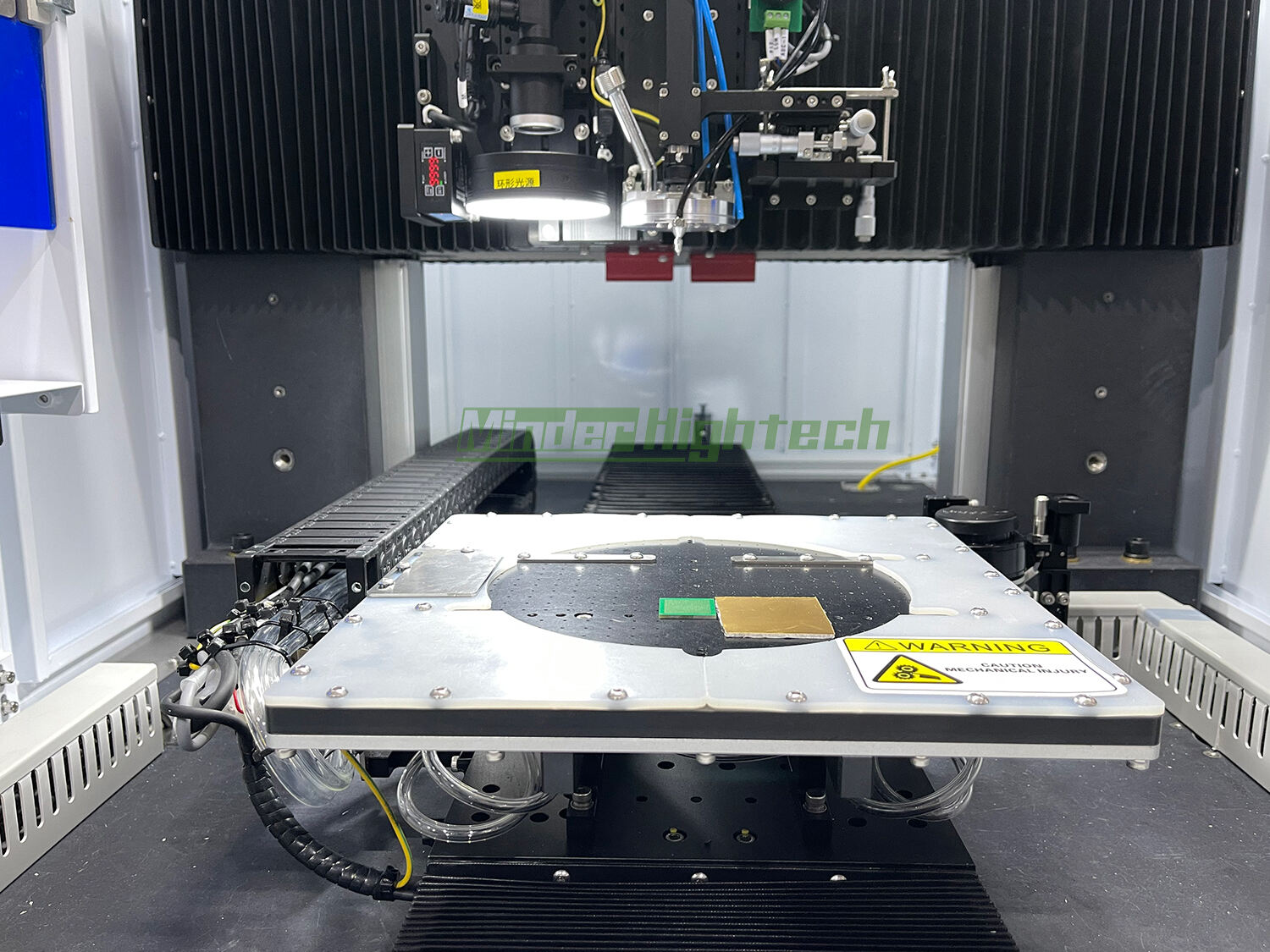

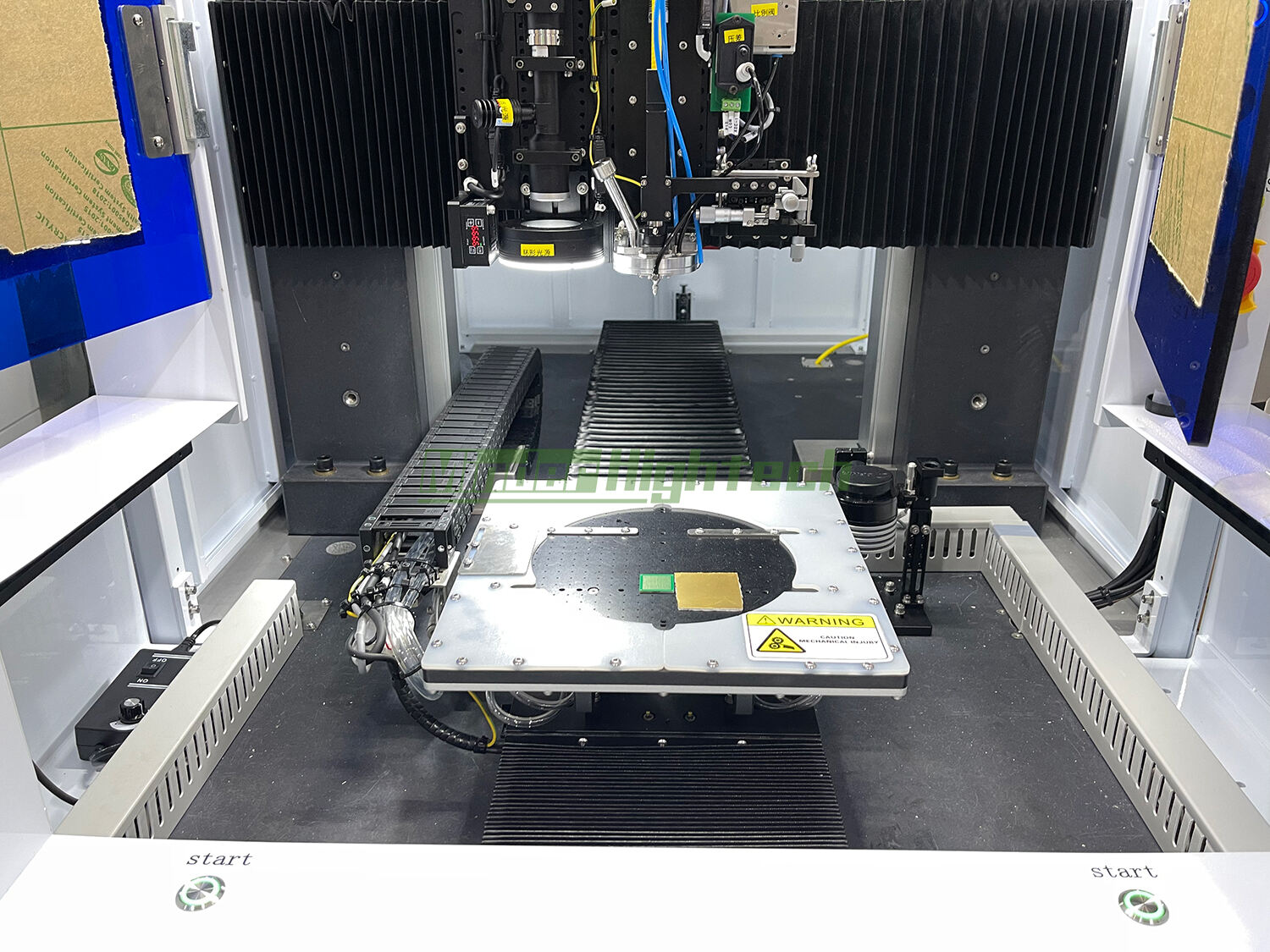

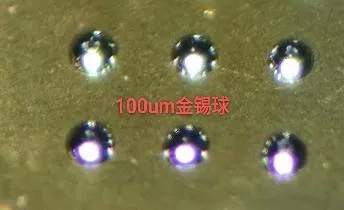

Placing ball diameter

|

200 um-760um

|

70 um-200um

|

70-760um

|

||

|

Motion control

|

PC+ motion control card

|

||||

|

Positioning method

|

CCD positioning

|

||||

|

2D inspection

|

Optional

|

Optional

|

Not available

|

||

|

Repetition precision

|

±5 um

|

±7um

|

±5um

|

||

|

Chuck table

|

Vacuum chuck

|

||||

|

Process range

|

150*150mm

|

||||

|

Ball planting efficiency

|

≥3 balls /S

|

||||

|

Nozzle counterpoint

|

Automatic calibration

|

||||

|

Power supply

|

AC220V 50Hz

|

||||

|

Computer

|

I5 ,win10

|

||||

|

Temperature and humidity

|

22-30°C 20-70% (non-condensating)

|

||||

|

Weight

|

1200Kg

|

1600 kg

|

1700kg

|

||

|

Overall dimensions

|

1200(L)*1350(W)*1800(H)mm

|

||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved