Facility requirements | ||

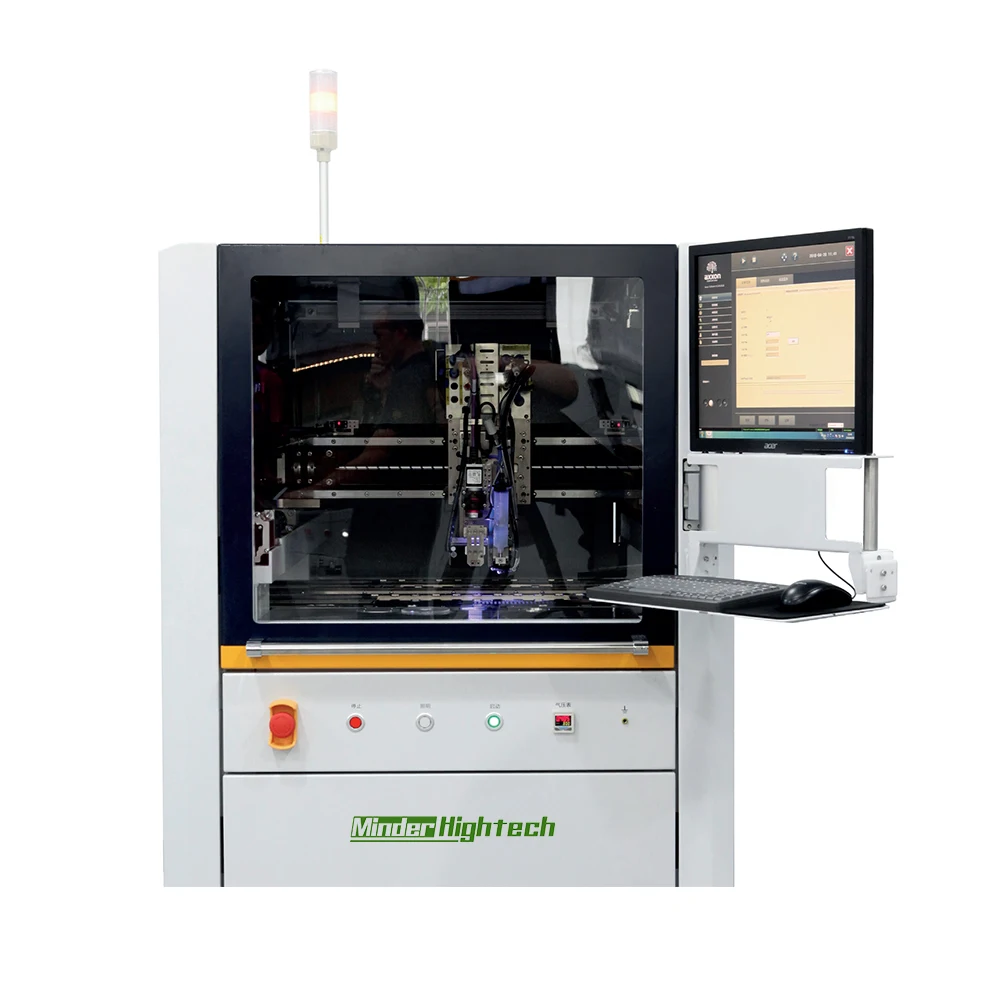

Power | AC230V 11A 50/60Hz 2.5KW(Power without trackheating) | |

Air supply | 90psi(6bar) | |

System dimention | 890*1500*1500mm(W'D*H) | |

System weight | 950 KG | |

Standard compliance | CE | |

Motion System | ||

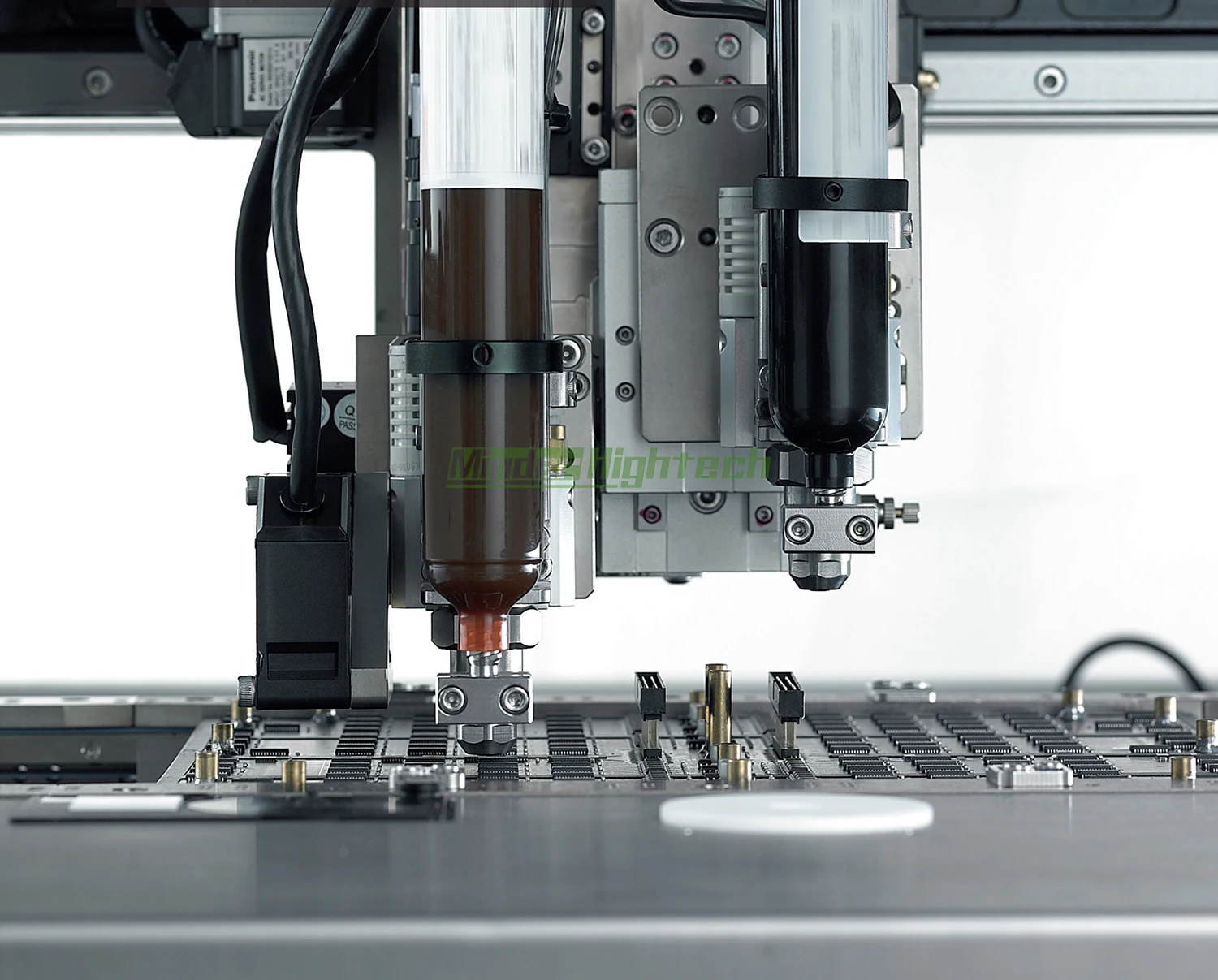

Positioning accuracy | XY: ±50um@3σ Z:±10um@3σ | |

XYZ Repeatability | XY: ±25um@3σ Z:±5um@3σ | |

Max speed | 1000mm/s(XY) | |

Acceleration | 1.0g | |

Drive system | Servo motor | |

Work platform parameters | ||

Track load-bearing capacity | 3KG | |

Track widening range | 40~760mm | |

Substrate thickness | 0.5~6mm | |

Operating System | Windows 7 | |

Communication Protocol | SMEMA | |

Board edge width | 5±2mm | |

Maximum height allowed for board mounted components | 45mm | |

Allow maximum height of components under the board | 23mm | |

Z-axis travel | 60mm | |

Dispense Area | ||

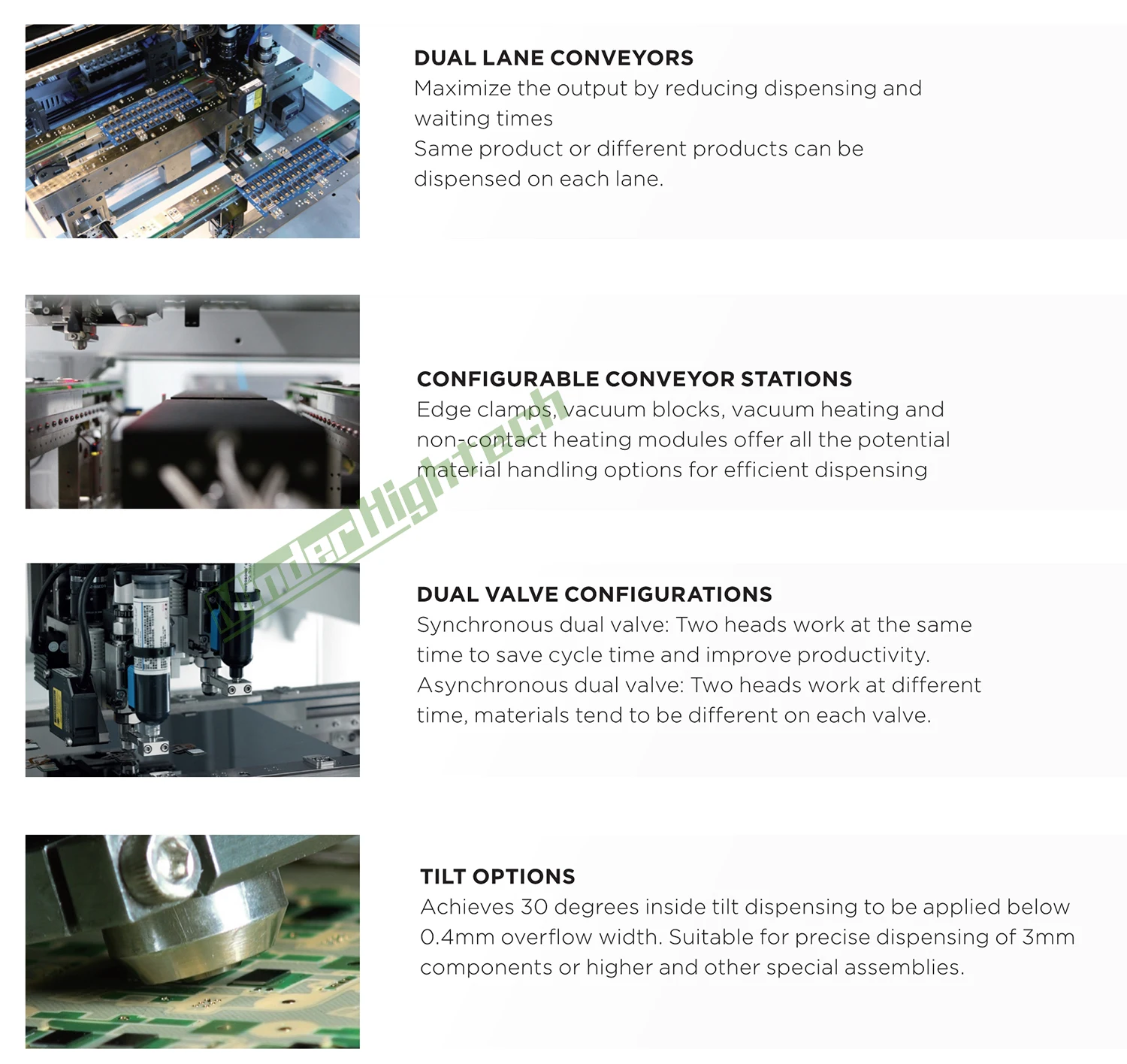

Maximum dispensing range (single track/double track) | 440mm*760mm/440mm*350mm(W*D) | |

Synchronous dual valve - manual adjustment (single track/double track) | 360mm*690mm/360mm*310mm(W*D ) | |

Synchronous dual valve automatic adjustment (single track/double track) | 360mm*670mm/360mm*300mm(W*D) | |

Asynchronous dual valve (single/double track) | 360mm*695mm/360mm*320mm(W*D) | |

Tilt&Rotate (Single/Double Track) | 300mm*660mm/300mm*300mm(W*D) | |

High precision tilting (single track/double track) | 280mm*680mm/280mm*305mm(W*D) | |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved