Product description

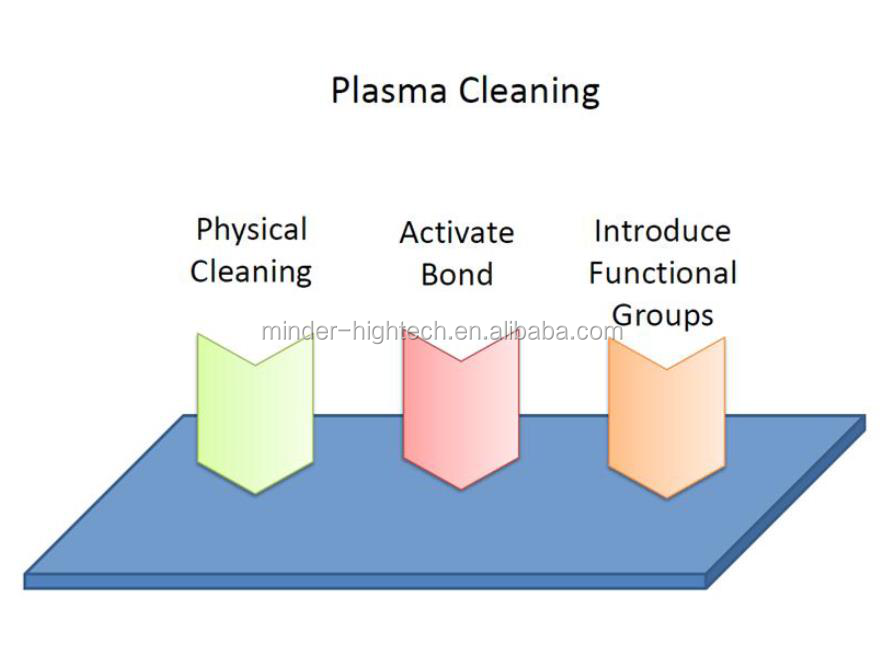

(1.1) The role of plasma cleaning

The principle of plasma cleaning is mainly:

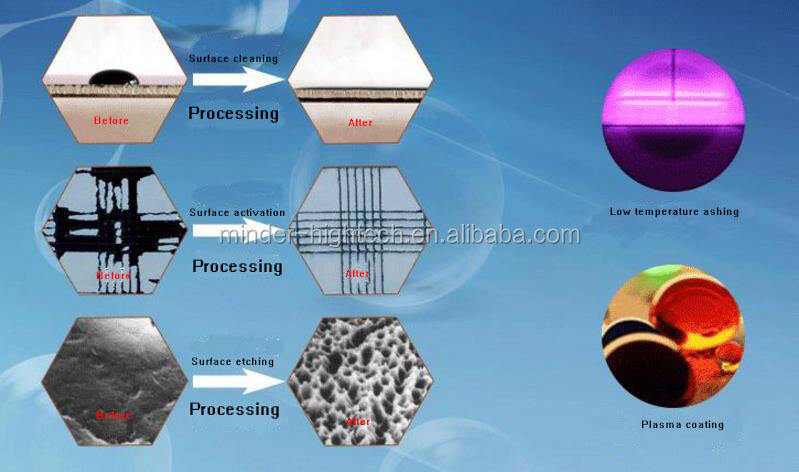

(A) Etching on the surface of materials - physical effects

A large number of active particles in the plasma, such as a large number of ions, excited molecules, and free radicals, act on the surface of the solid sample, which not only removes the original contaminants and impurities, but also produces an etching effect to roughen the surface of the sample. Many fine pits are formed, increasing the surface ratio of the sample. Improve the wetting properties of solid surfaces.

(B) Activation bond energy, cross-linking

The energy of the particles in the plasma is between 0-20 eV, and most of the bonds in the polymer are between 0-10 eV.

When a solid surface is used, the original chemical bond on the solid surface can be broken, and the free radicals in the plasma and these bonds

The formation of a network of crosslinked structures greatly activates surface activity.

(C) Forming new functional groups - chemistry

If a reactive gas is introduced into the discharge gas, a complicated chemical reaction occurs on the surface of the activated material, and new functional groups such as a hydrocarbon group, an amino group, a carboxyl group, and the like are introduced, and these functional groups are all active groups, which can significantly improve the surface activity of the material.

Product principle:

1. Principle of structural composition: The structure of atmospheric low-temperature plasma cleaning machine is divided into three parts: high-voltage excitation power supply, plasma generator spray gun, and intelligent control system.

1.1 High-voltage excitation power supply: Plasma generation requires high-voltage excitation. Atmospheric low-temperature plasma is excited by medium-frequency power supply. The frequency is 10-40KHz, and the high voltage is 10KV. The parameters can be adjusted according to the actual conditions of the product, with excellent and stable treatment effect.

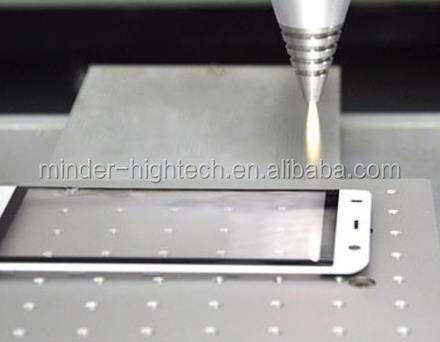

1.2 Plasma generator spray gun: atmospheric low-temperature plasma generator spray gun, can be divided into two types of jet direct injection and rotary direct injection, the difference is that the processing area is different, and can be combined with automated production line solutions according to customer needs.

1.3 Intelligent Control System: The function of the control system is to control the operation of the entire atmospheric low-temperature plasma cleaning equipment, power regulation, and various protections of the overall system.

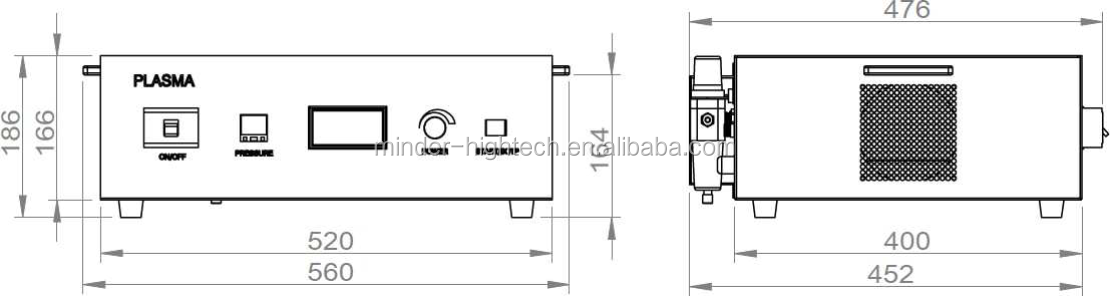

Technical Parameters

| Model | SPA-2600 | |

| Power | 300-500W (Adjustable) | |

| Dimension | 560*452*186mm (W*H*D) | |

| Input power supply | 220V 50/60Hz | |

| High voltage frequency | 50KHz | |

| Processing width | 2mm, 3mm, 5mm, 7mm | |

| Remote control | Support | |

| Process gas | Compressed air | |

| Weight | 20kg | |

Performance advantage

1. German circuit technology:

High-density plasma is generated by imported high-voltage excitation power circuit technology to ensure superior cleaning results

2. Unique discharge technology:

Special treatment and special structure of the discharge device to ensure a stable and uniform plasma

3. With assembly line production:

According to the needs of the user on site, configure the optimal production line to greatly improve production efficiency.

4. Low temperature cleaning:

According to the temperature requirements of different occasions, it does not affect the temperature of the cleaning products.

5. Quality product parts:

All parts of the product are made of imported top quality parts to ensure superior equipment performance.

6. Precision CNC machining: imported precision CNC machine tool processing technology, and equipped with imported three-coordinate measuring instrument for quality monitoring

7. Comprehensive security protection:

Temperature safety protection function, overload protection function, air pressure abnormality protection function, short circuit breaking alarm protection function, various operation protection functions

Application industry:

Wide range of cleaning and activation applications, professionally used in mobile phone screens, PE, PP, PVC, PET, ceramics, glass, lithium batteries, rubber, polymer materials, etc.

Plasma generator dimensional drawings:

Our Factory:

Help customer analyze product project and provide cleaning solution.

Freely sample cleaning test.

Provide professional cleaning solution.

Skilled jig design services.

Provide shipping/delivery information checking service.

One year guarantee, all life maintain promise.

24 hours feedback speed by email of others.

Minder-Hightech's Plasma Surface Treatment Machine is an ingenious and progressed tool perfect for the processing of Pet Coated Cardboard.

Pet Coated Cardboard is a type of cardboard is coated along with a polyethylene terephthalate (PET) product for enhanced wetness protection and resilience. It is produced through the covering difficult for the cardboard towards bond along with various other products, creating it difficult towards procedure without specific equipment where Minder-Hightech's Plasma Surface Treatment Machine is available in towards source the service towards the problem.

This cutting-edge machine uses plasma innovation towards deal with the surface of your Pet Coated Cardboard, enhancing its own residential or commercial homes which can be sticky. The Plasma Surface Treatment Machine eliminates the surface pollutants, triggers teams that are practical and offers attire and managed surface powers towards the product towards advertise adhesion, bonding, level, and publishing. The Plasma Surface Treatment Machine guarantees that the Pet Coated Cardboard ought to be capable towards bond easily along with various other products, creating it easier towards transfer and bundle.

Simple towards run, extremely flexible, and effective. The machine is geared up along with a software application is easy to use in addition to the procedure specifications can be quickly personalized based upon the specific requirements of a private. The gadget is likewise produced for constant treatment and consists of a processing ability is higher. This will create it perfect for massive production, integrating worth towards the manufacturing procedure through increasing efficiency and effectiveness.

Developed towards last, along with a building is durable assurances durability and resilience. The gadget was place with screening is extensive quality control, guaranteeing that it fulfills market requirements for safety, satisfaction, and efficiency. The company currently provides client is outstanding, along with technological support offered for all of clients.

Obtain the Minder-Hightech's Plasma Surface Treatment Machine today, and sign up with the exclusive team of producers and suppliers that are reaping the advantages of this particular amazing devices.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved