Item |

MD150-RIE |

MD200-RIE |

MD200C-RIE |

||

Product size |

≤6 inches |

≤8 inches |

≤8 inches |

||

RF power source |

0-300W/500W/1000W Adjustable, automatic matching |

||||

Molecular pump |

-/620(L/s)/1300(L/s)/Custom |

Antiseptic620(L/s)/1300(L/s)/Custom |

|||

Foreline pump |

Mechanical pump/dry pump |

Dry pump |

|||

Process pressure |

Uncontrolled pressure/0-1Torr controlled pressure |

||||

Gas type |

H/CH4/O2/N2/Ar/SF6/CF4/ CHF3/C4F8/NF3/Custom (Up to 9 channels, no corrosive & toxic gas) |

H2/CH4/O2/N2/Ar/F6/CF4/ CHF3/C4F8/NF3/Cl2/BCl3/HBr(Up to 9 channels) |

|||

Gas range |

0~5sccm/50sccm/100sccm/200sccm/300sccm/500sccm/custom |

||||

LoadLock |

Yes/No |

Yes |

|||

Sample tem control |

10°C~Room tem/-30°C~100°C/Custom |

-30°C~100°C /Custom |

|||

Back helium cooling |

Yes/No |

Yes |

|||

Process cavity lining |

Yes/No |

Yes |

|||

Cavity wall tem control |

No/Roomtem~60/120°C |

Room tem-60/120°C |

|||

Control System |

Auto/custom |

||||

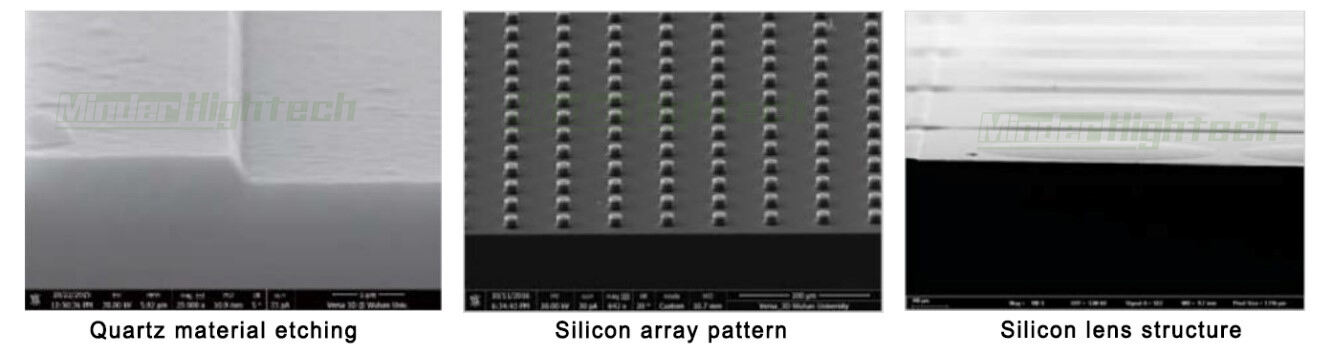

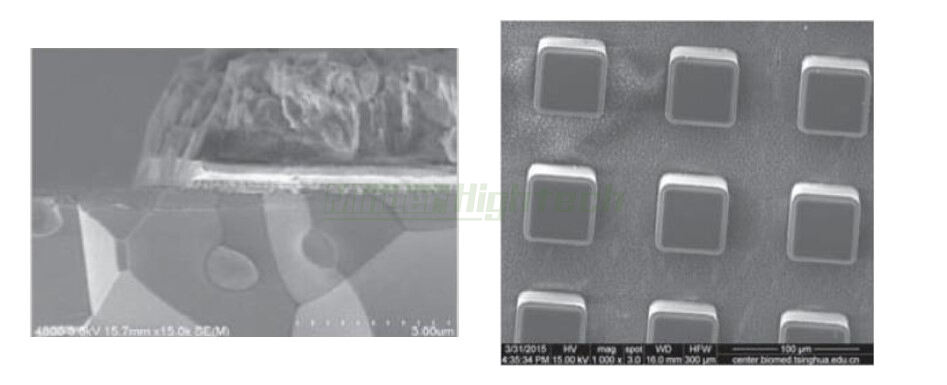

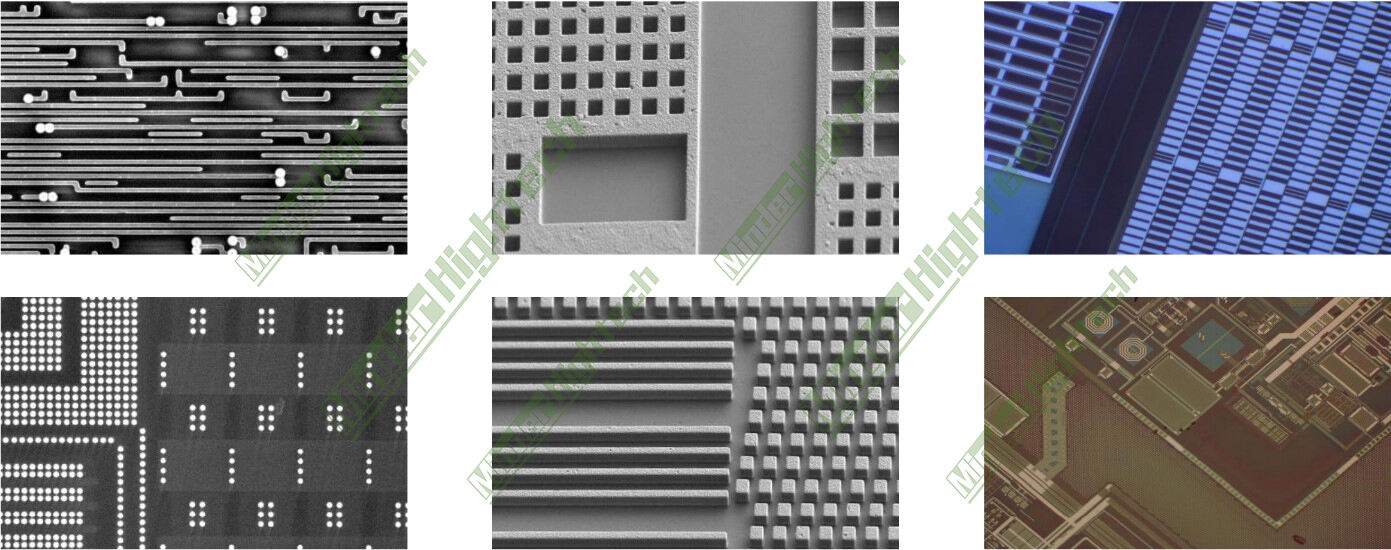

Etching material |

Silicon-based:Si/SiO2/SiNx. IV-IV: SiC Magnetic materials/alloy materials Metallic material: Ni/Cr/Al/Au. Organic material: PR/PMMA/HDMS/Organic film. |

Silicon-based: Si/SiO2/SiNx. III-V(注3): InP/GaAs/GaN. IV-IV: SiC II-VI (注3): CdTe. Magnetic materials/alloy materials Metallic material: Ni/Cr/A1/Au. Organic material: PR/PMMA/HDMS /organic film. |

|||

Suitable for microwave devices, power devices, etc.

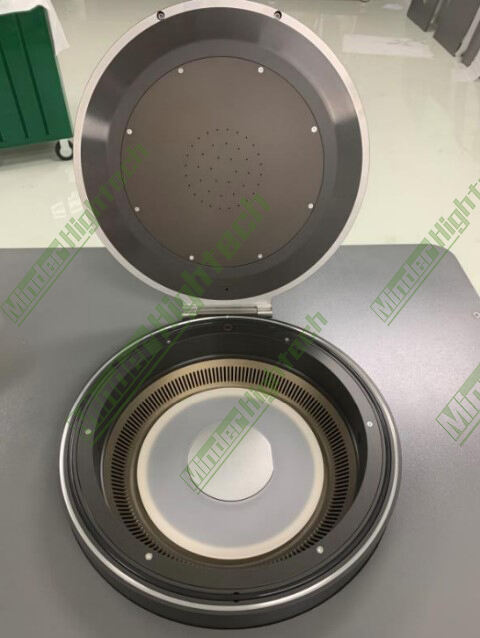

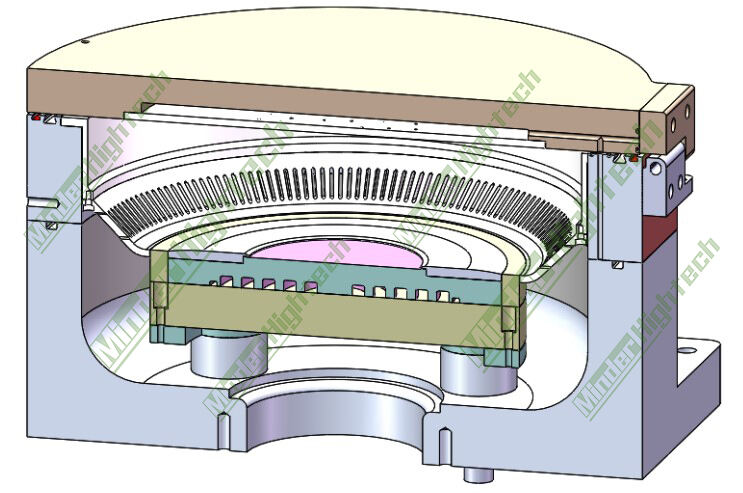

The Minder-High-tech Reactive Ion Etching (RIE) machine is a state-of-the-art piece of technology that can etch and analyze various types of materials with incredible precision. This machine is designed for use in various industries where microfabrication or etching is required regularly. It is made from high-quality materials that make it durable, reliable and able to produce excellent results.

Equipped with a RF plasma generator is effective. The RIE system uses a coupling is inductive to come up with plasma from the feed gasoline. This technique creates a plasma is high-density that increases the etch rate associated with product. The etching process of the RIE machine is effective, accurate, and highly controllable, allowing for a depth is specific of to be accomplished. This feature is unique it a great choice for research or industry works.

The machine has a range is wide of, including microelectronics, MEMS fabrication, and semiconductor fabrication. This machine plays an important role in etching and micromachining of semiconductor materials like silicon, gallium arsenide, and germanium in the semiconductor industry. The Minder-High-tech RIE device has additionally been established in the MEMS industry for fabricating soft and materials that are hard as polyimide, silicon dioxide, and silicon nitride. Additionally, it is accessible for failure analysis in industries associated with services and products that are electronic.

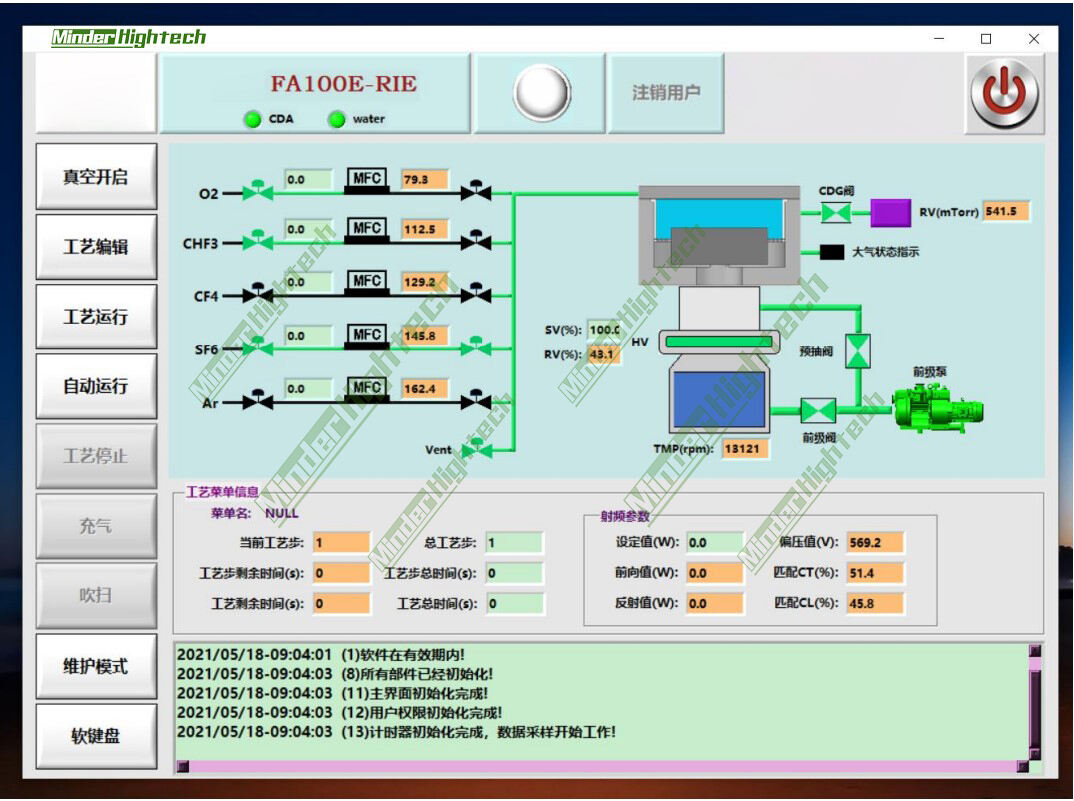

Includes features which are various make it easy to utilize. It's a software is user-friendly supplies the operator complete control over the etching parameters utilized in the device. The machine settings are saved to its memory is internal it can store over 100 sets of settings. A touch is had by it screen which allows the operator setting parameters like gas movement, power thickness, and pressure. The Minder-High-tech RIE machine also has a temperature control feature that ensures that the materials are etched at the right temperature and stops damage to them.

Perfect for companies that require a reliable and machine is efficient can provide accurate and precise outcomes. This device has been designed with top-notch technology and a level is a lot of. Its versatility and user-friendly features make it a choice is very good research and industry applications across different sectors.

It also has an efficient failure analysis system that enables the machine to detect and correct any mechanical issues as soon as possible. This system ensures that the RIE machine maintains high quality and reliability throughout its life cycle. For any industry that requires precise and efficient etching or microfabrication, the Minder-High-tech RIE machine is the perfect solution.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved