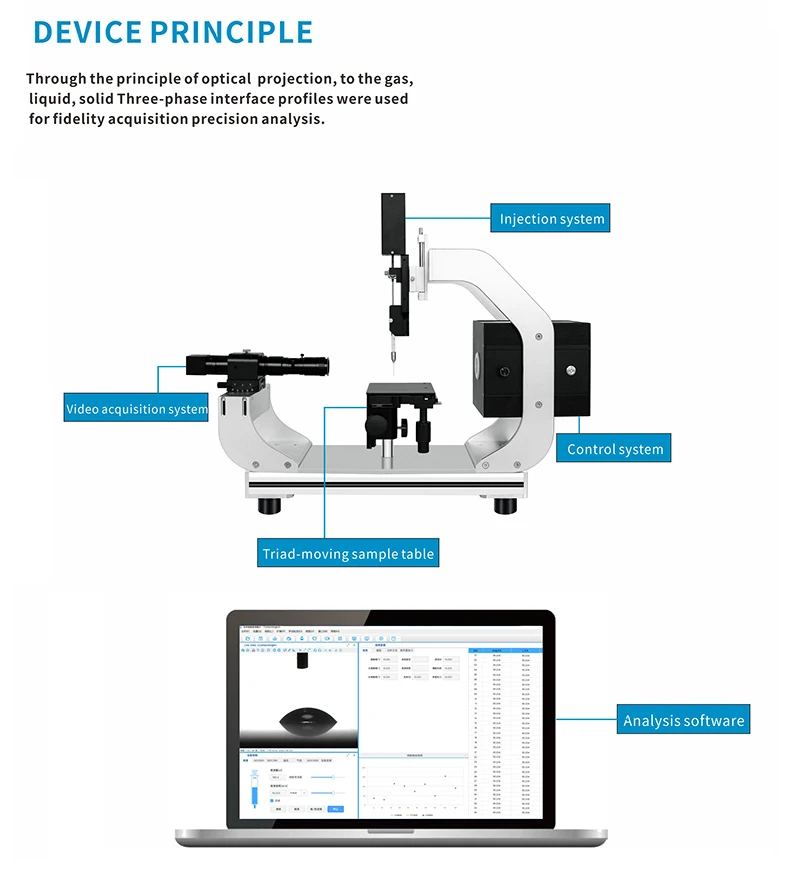

Specification of equipment | ||

Equipment host | ||

outline dimension | 760mm (long) 380mm (W) 700mm (height) | |

weight | 21KG | |

Machine adjustment | Complete machine level test / adjustment | |

source | ||

voltage | 100~240VAC | |

power | 150W | |

frequency | 50/60HZ | |

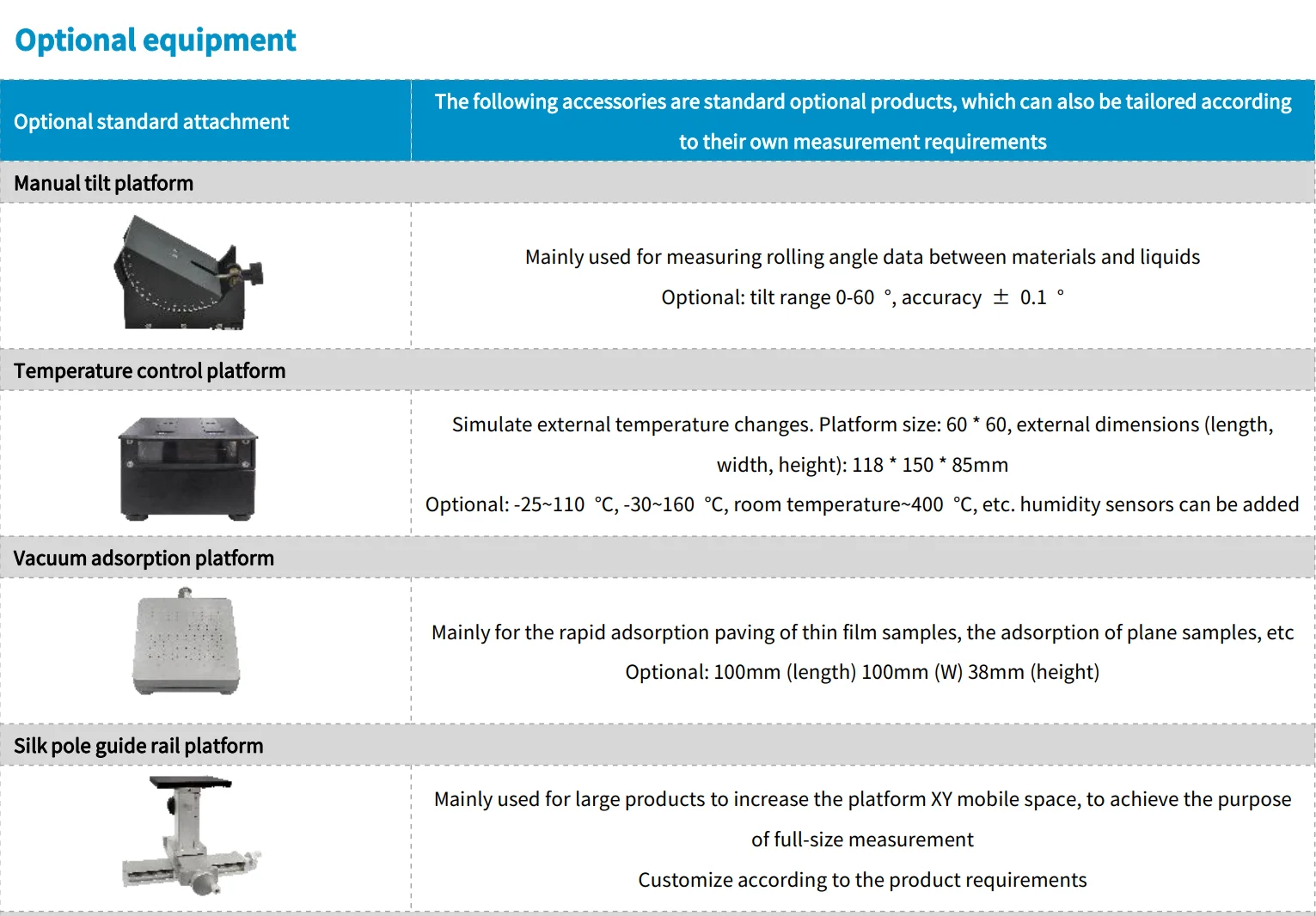

space | ||

Platform size | 130mm×170mm | |

Maximum sample | 260×∞×15mm | |

Sample table adjustment | Fully automatic mobile platform | |

Before and after the manual adjustment, travel 180mm, precision 0.1mm Left and right of manual adjustment, travel 120mm, precision 0.1mm Up and down manual adjustment, travel 20mm, accuracy 0.1mm | ||

picture pick-up system | ||

Maximum image | 5000(H)× 4000(V) | |

Maximum frame rate | 200 fps (upgraded for higher frames) | |

sensor | SONY 1/1.8" | |

light spectrum | Black and white / color | |

ROI | user-defined | |

Show line width | user-defined | |

exposure time | user-defined | |

source | The 5-VDC USB interface | |

transfer | USB3 Vision | |

Microscope head | ||

focal distance | 130mm ± 5mm (zoom adjustment) | |

multiplying power | 10 Times | |

Perspective adjustment | ±10° | |

Resolution scaling | 4~14um | |

Collection system regulation | Top / up / flat | |

illuminant | ||

type | Single-wavelength industrial LED (cold light) | |

wavelength | 470nm | |

light field | φ50mm | |

light-spot | 96 Grain intensive | |

life span | 50000Hour | |

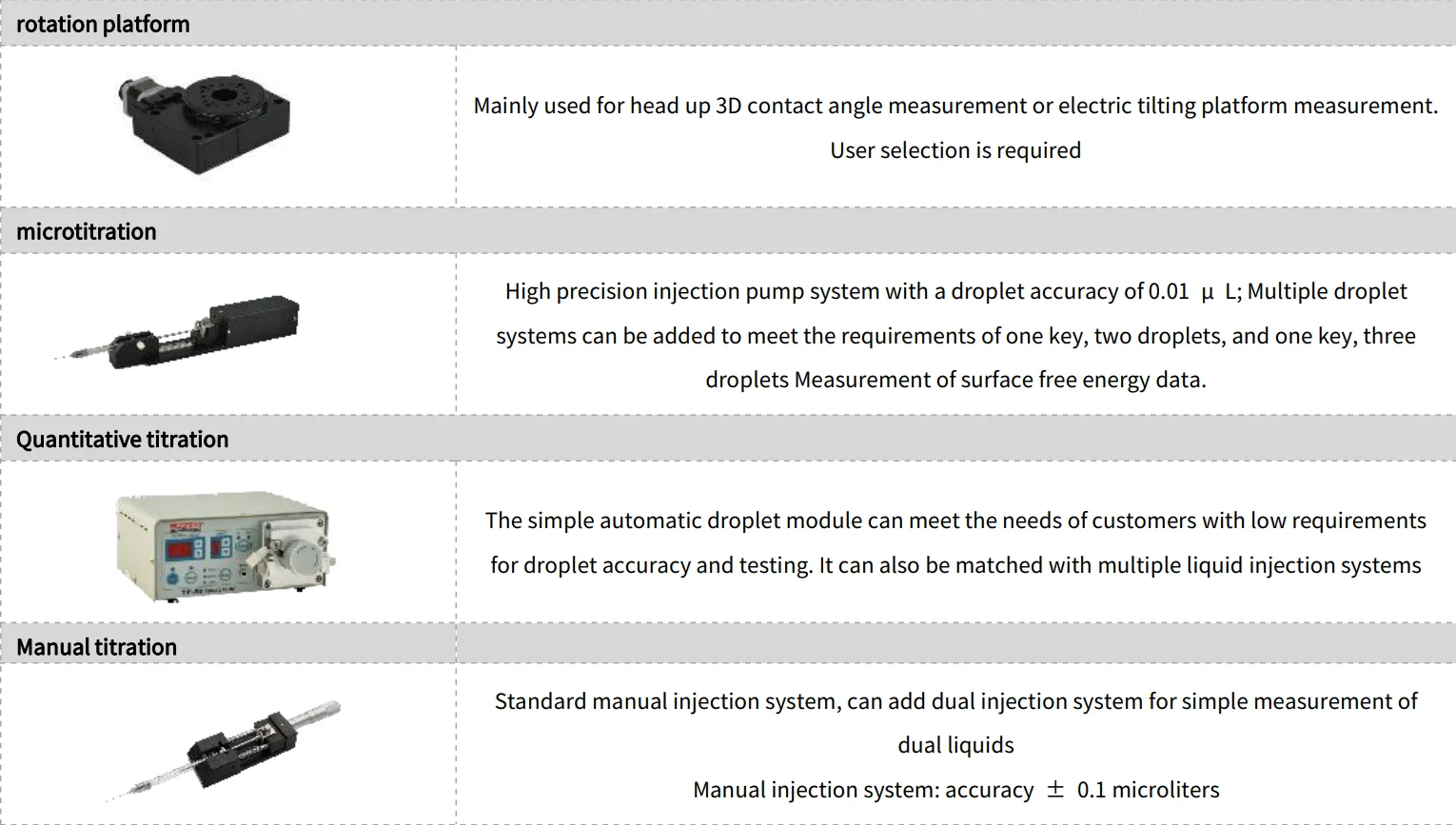

Injection system | ||

Dropping method | Precision microinjection pump | |

control method | Software digital control | |

Dropping precision | 0.01μl | |

injector | High-precision air-tightness syringe | |

Method of liquid connection | Precision motor control | |

injector | High-precision air-tightness syringe | |

capacity | 100 μ l / 500 μ l / 1000 μ l (standard 500 μ l) | |

pinhead | 0.51mm all stainless steel superhydrophobic needle (standard standard) | |

velocity | 1μL/min ~2000μL/min | |

software | ||

Contact angle range | 0~180° | |

resolution ratio | 0.01° | |

Automatic measurement | Automatic one-click measurement function (Programmable test point, multi-point automatic measurement) | |

Maximum amount of data | One-click analysis of> 10 numerical values | |

Morphological spectra | Spectrum map of the 2D morphological data | |

Contact angle measurement method | Fully automatic, semi-automatic, and manual work | |

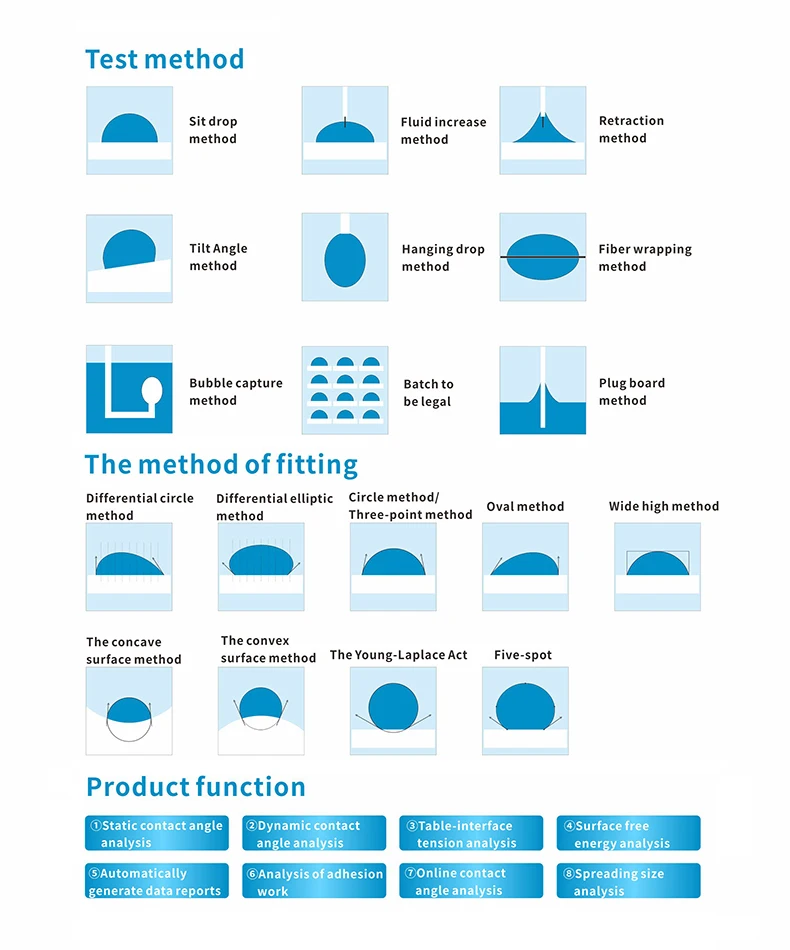

analysis mode | Suspension drop method, stop drop method (2 / 3 state), bubble capture method, seat drop method, pin needle method, insert plate method | |

analytic procedure | Static analysis, dynamic analysis of automatic fluid expansion, wetting dynamic analysis, real-time analysis, bilateral analysis, forward and backward Angle analysis | |

test method | Circle method, ellipse / oblique ellipse method, differential circle / differential ellipse method, Young-lapalace, width and height method, tangent method, interval method | |

Table / Interface tension test | ||

test specification | 0~3000mN/m | |

resolution ratio | 0.01 mN/m | |

Tension measurement mode | full-automation | |

analysis mode | Bubble capture method, hanging drop method, and real-time spectrogram | |

surface free energy | ||

test method | Zisman, OWRK, WU, WU 2, Fowkes, Antonow, Berthelot, EOS, adhesion work, immersion work, and spreading coefficient | |

data handling | ||

Output method | Automatic generation, can export / print EXCEL, Word, spectrogram and other report formats | |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved