Function |

Describe |

Notes |

Display mode |

Touch screen |

|

Control mode |

PLC |

|

Mechanical pump pumping speed |

4L/s |

Bipolar rotary vane vacuum pump |

Dimensions of pressurized helium/pressurized fluorine oil tanks |

F150×200(mm) |

Customizable size |

vacuum degree |

≤45Pa |

|

Helium filling pressure |

0.2-0.6Mpa, adjustable |

|

Pressure holding time |

1-10 hours, adjustable |

Name |

Describe |

Quantity |

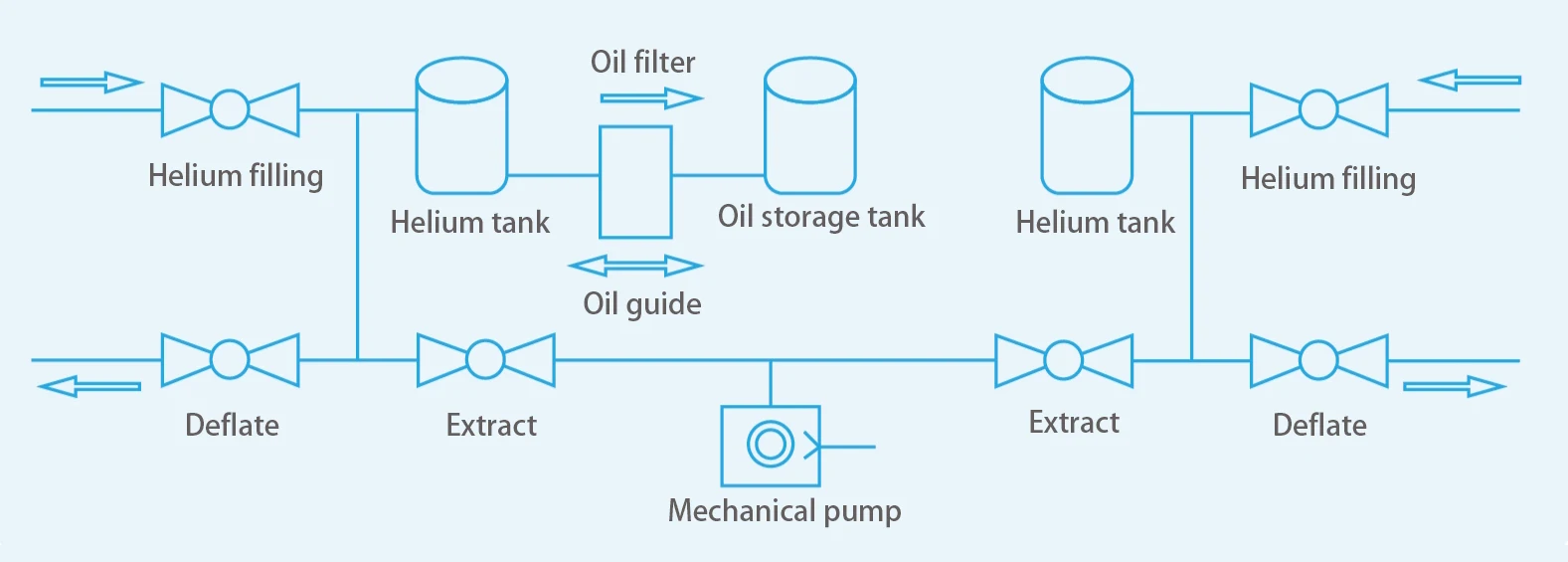

Mechanical pump |

4L/s |

1 piece |

Pressurized helium tank |

F150×200(mm) |

1 piece |

Fluorine pressurized oil tank |

F150×200(mm) |

1 piece |

Storage tank |

F215×250mm |

1 piece |

Solenoid valve |

CKD/ASCO |

1 set |

Pressure sensor |

Meas |

1 set |

Liquid level meter |

HOARE |

1 set |

piping |

HOARE |

1 set |

Electric control system |

HOARE |

1 set |

Light fluorine oil (optional) |

Minder-Hightech |

1 drum (20KG) |

Working temperature range |

125℃±5℃ |

heating rate |

Heat from room temperature to 125 ℃ ≤30 minutes |

Container size |

240*165*180mm(W*D*H) |

Observation window size |

200*135mm |

Observation window function |

Equipped with an adjustable angle magnifying glass |

Leak detection time setting |

Can set timed alarms |

Drain the oil |

The container is equipped with an oil discharge port |

Filtering function (optional) |

It has a circulating filtration function that can filter out 1μm impurities in heavy fluorine oil |

Name |

Describe |

Quantity |

Oil heating system |

/ |

1 set |

Electrical control part |

/ |

1 set |

Heavy fluorine oil container |

/ |

1 |

magnifier |

Adjustable angle, 3x |

1 |

Light bulb: |

/ |

2 |

Retrieval device |

1 size each |

2 |

Heavy fluorine oil (optional) |

import |

5Kg |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved