XY placement accuracy |

±0.4 mil (±10 µm) @ 3σ |

Chip deflection |

|

5 mm

|

±0.15° @ 3σ |

1 mm |

±0.3° @ 3σ |

0.25 mm |

±1° @ 3σ |

Die bond mode |

|

XY Welding position accuracy |

±1 mil (±25 µm) @ 3σ |

Chip deflection |

|

Die size ≥ 1 mm |

±0.5° @ 3σ |

Die size |

±1° @ 3σ |

Material processing capacity |

|

Die size |

0.25x0.25 mm2–10x10mm2 |

Wafer size |

|

standard |

12” (300 mm) |

optional |

6” (150 mm) / 8” (200 mm) |

Lead frame size |

|

Length |

100 – 300 mm |

width |

15 – 100mm |

height |

|

standard |

0.1 – 0.8 mm |

optional |

0.8 – 2.0 mm |

Box size |

|

Length |

110 – 310 mm |

width |

20 – 110 mm |

height |

70 – 153 mm |

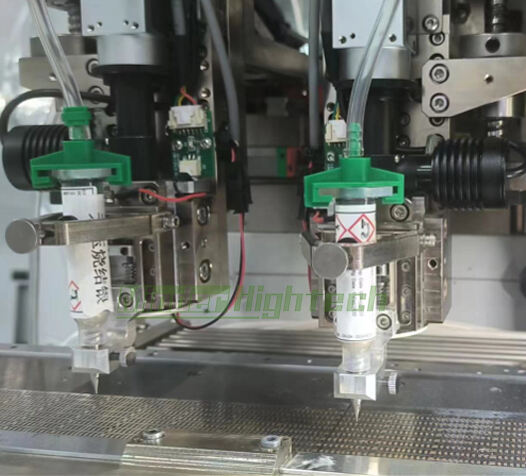

Welding head system |

|

Die bond pressure |

30 – 3,000 g (Programmable) |

Image recognition system |

|

Image recognition system |

256 grayscale levels |

Required facilities |

|

voltage |

110/120/220/240 VAC |

frequency |

50/60 Hz (Factory pre-set) |

Maximum load current |

10.5A @ 220 V |

compressed air |

minimum 87 PSI (6 bar) |

Number of compressed air inlets |

2 (Ø10mm outer diameter of rubber hose) |

consumption |

1,800 W (Equipped with heater) 1,500 W (Not equipped with heater) |

Dimension |

|

size |

Width x depth x height |

Including the loading and unloading lifting platform |

93.7” x 56.3” x 76.2” (2,380 mm x 1,430 mm x 1,935 mm) |

weight |

3960 pounds (1,800 kg) |

The Minder-Hightech Semiconductor Equipment Automatic Electrical Bonder is a cutting-edge machine for bonding semiconductors towards a wide range of bundles. This gadget is ideal for high-precision requests that need severe repeatability and precision.

Utilizes a mix of automated and handbook bodies towards ensure the positioning is perfect of package and die prior to the bond is produced. This guarantees a solid, dependable bond that can final for years to find.

Among the most outstanding functions is its own user-friendly, easy to use user interface. Everybody can easily discover simply ways to utilize this machine. The software application offers detailed directions that direct individuals with the treatment for bonding the package towards the die.

It is furthermore incredibly flexible. It is efficient in bonding a variety is broad of dimensions towards an also larger variety of bundles. This creates it ideal for utilize in a selection of markets, consisting of electronic devices, aerospace, and telecom.

Likewise, extremely effective. It is along with the capability of bonding several passes away in a operate is solitary protecting sources and opportunity. This creates it a service is affordable business that have to bond huge amounts of bundles easily and rapidly.

In regards to accuracy, it is the finest. It uses imaging is progressed towards ensure that every bond is ideal, likewise for micro-sized bundles and passes away. This guarantees that every package is resilient and dependable, also under severe problems.

The Minder-Hightech Semiconductor Equipment Automatic Electrical Bonder is the ideal service for experts that need unparalleled accuracy, effectiveness, and flexibility. Whether you are operating in electronic devices, telecom, or even aerospace, this gadget is an essential for any type of laboratory or even workshop. Attempt it out on your own today, and view why a lot of experts count on the Minder-Hightech brand name for every one of their bonding requirements.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved