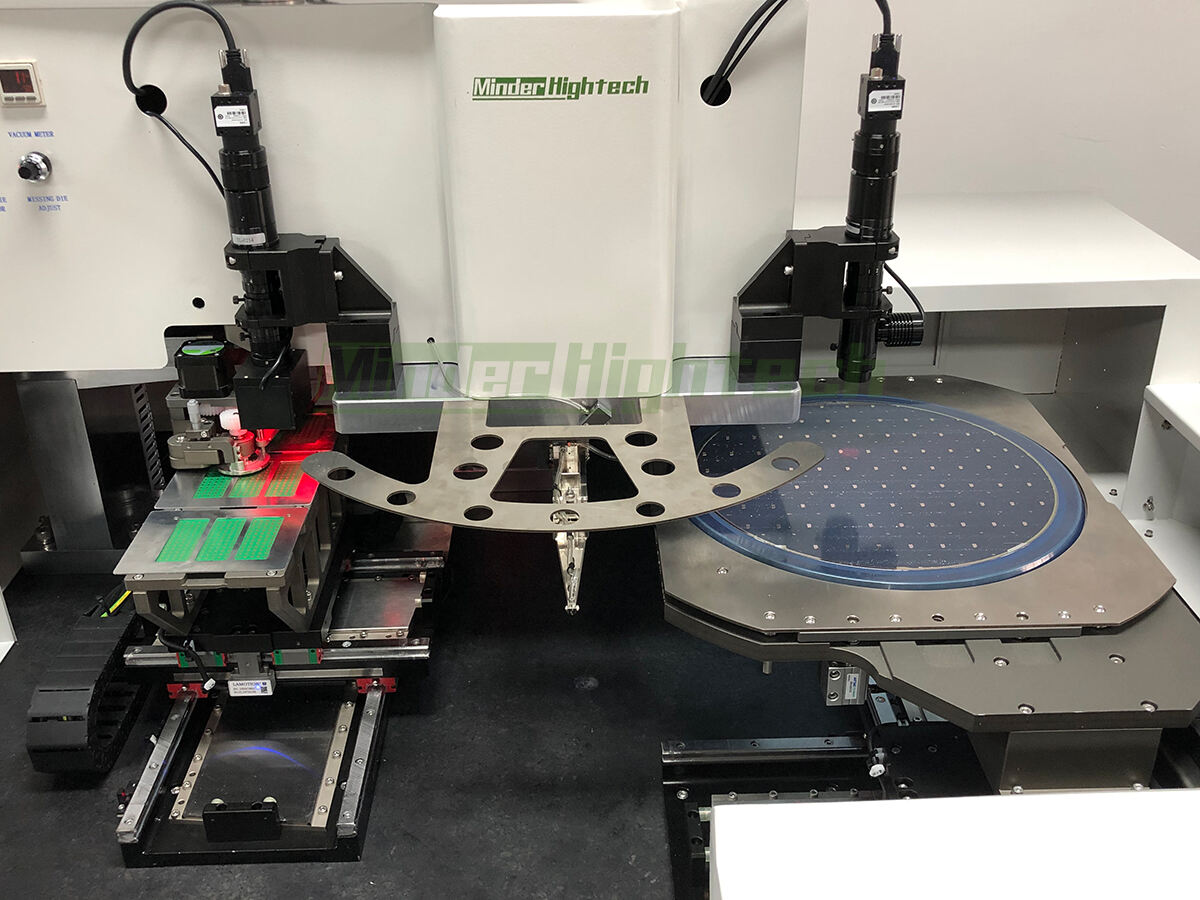

Application

Suitable for: SMD HIGH-POWER COB, part COM in-line package etc.

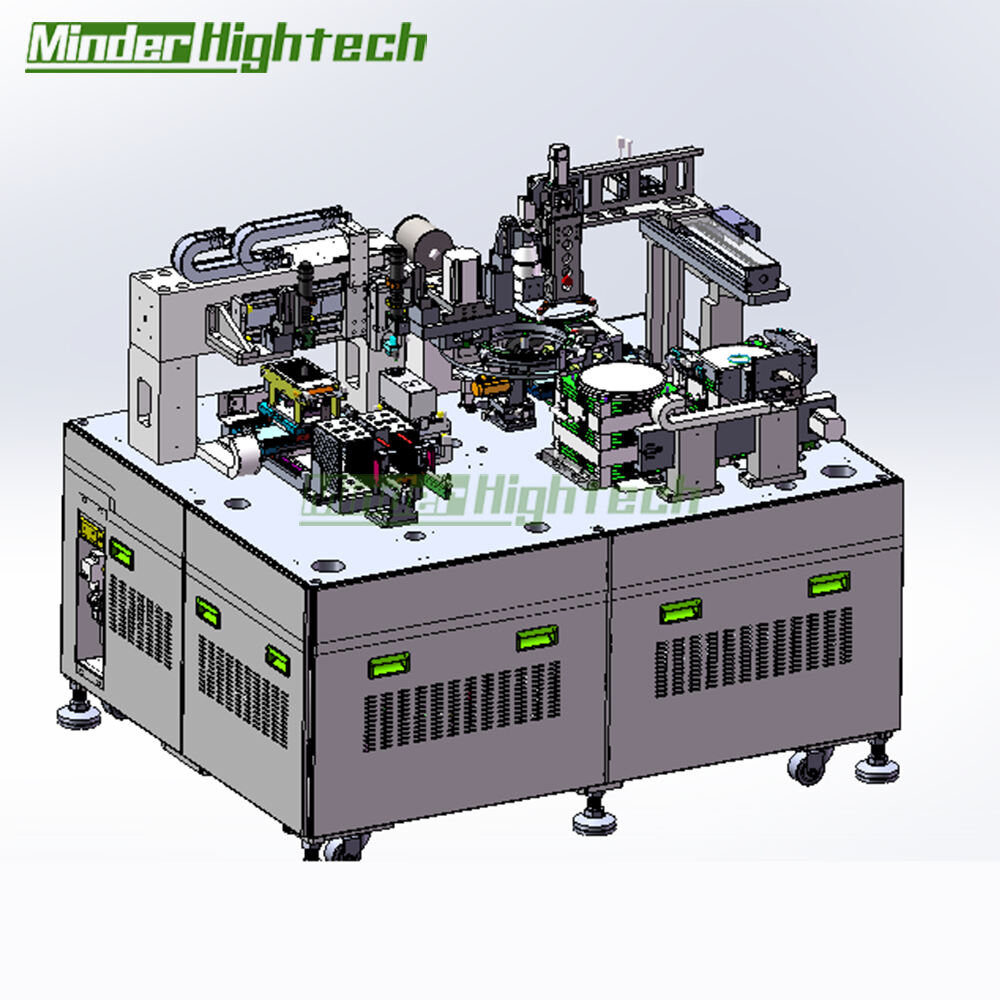

1, Fully automatic up load and down load materials.

2, Module design, ax optimization structure.

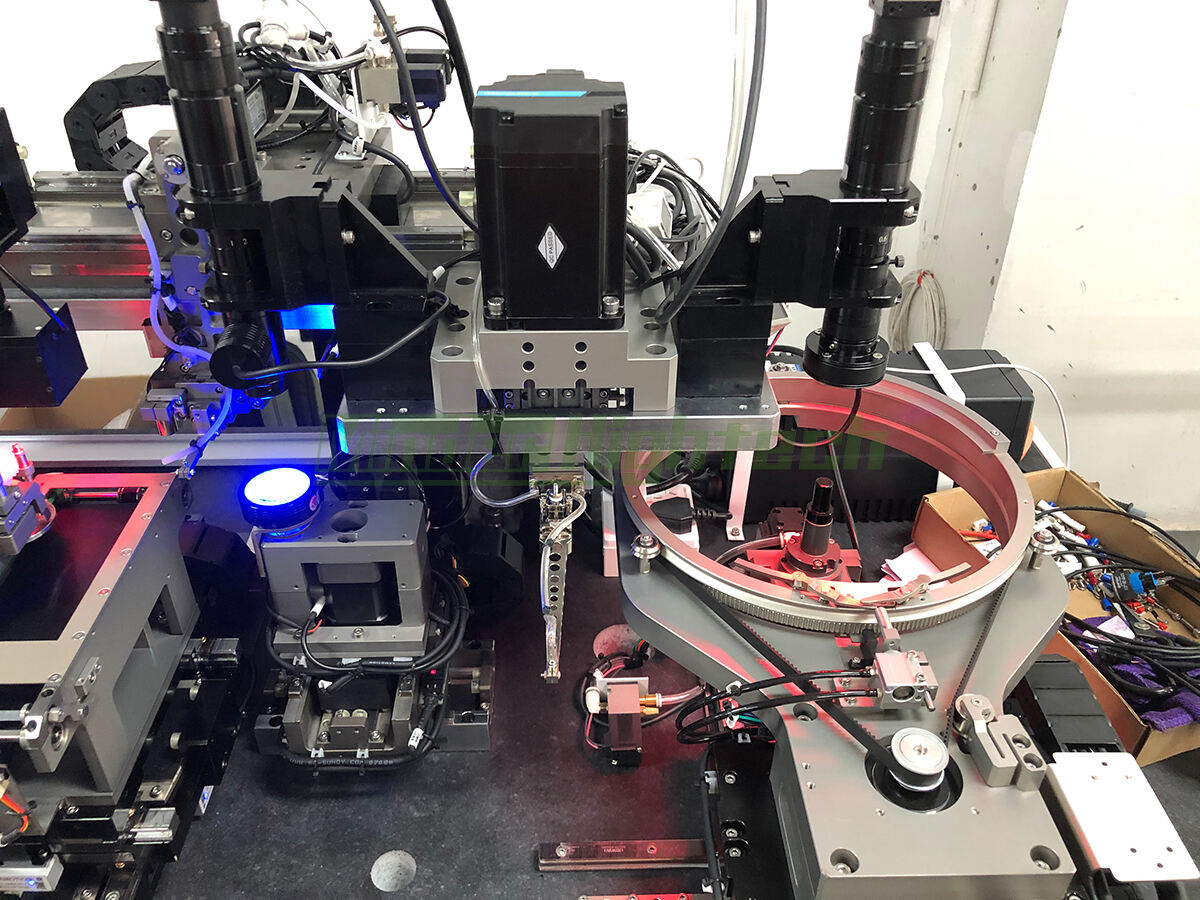

3, Full intellectual property right.

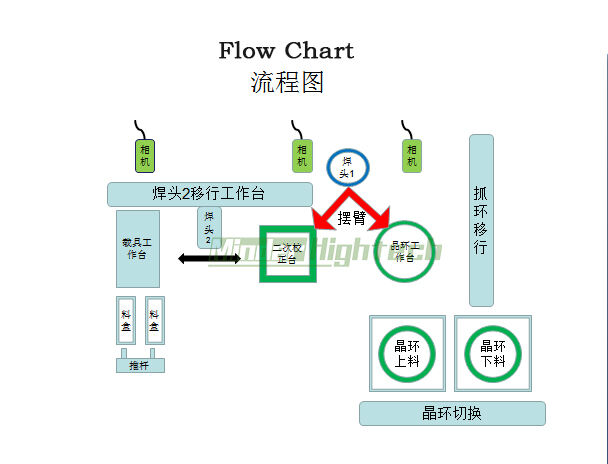

4, Picking die and Bonding die dual PR system.

5, Multi-wafer ring, dual glue etc. configuration.

Bonding workstage |

||

Load ability |

1 piece |

|

XY stroke |

10inch*6inch(working range 6inch*2inch) |

|

Accuracy |

0.2mil/5um |

|

Dual work stage can feed continuously |

||

Wafer workstage |

||

XY travel stroke |

6inch*6inch |

|

Accuracy |

0.2mil/5um |

|

Wafer position accuracy |

+-1.5mil |

|

Angle accuracy |

+-3 degree |

|

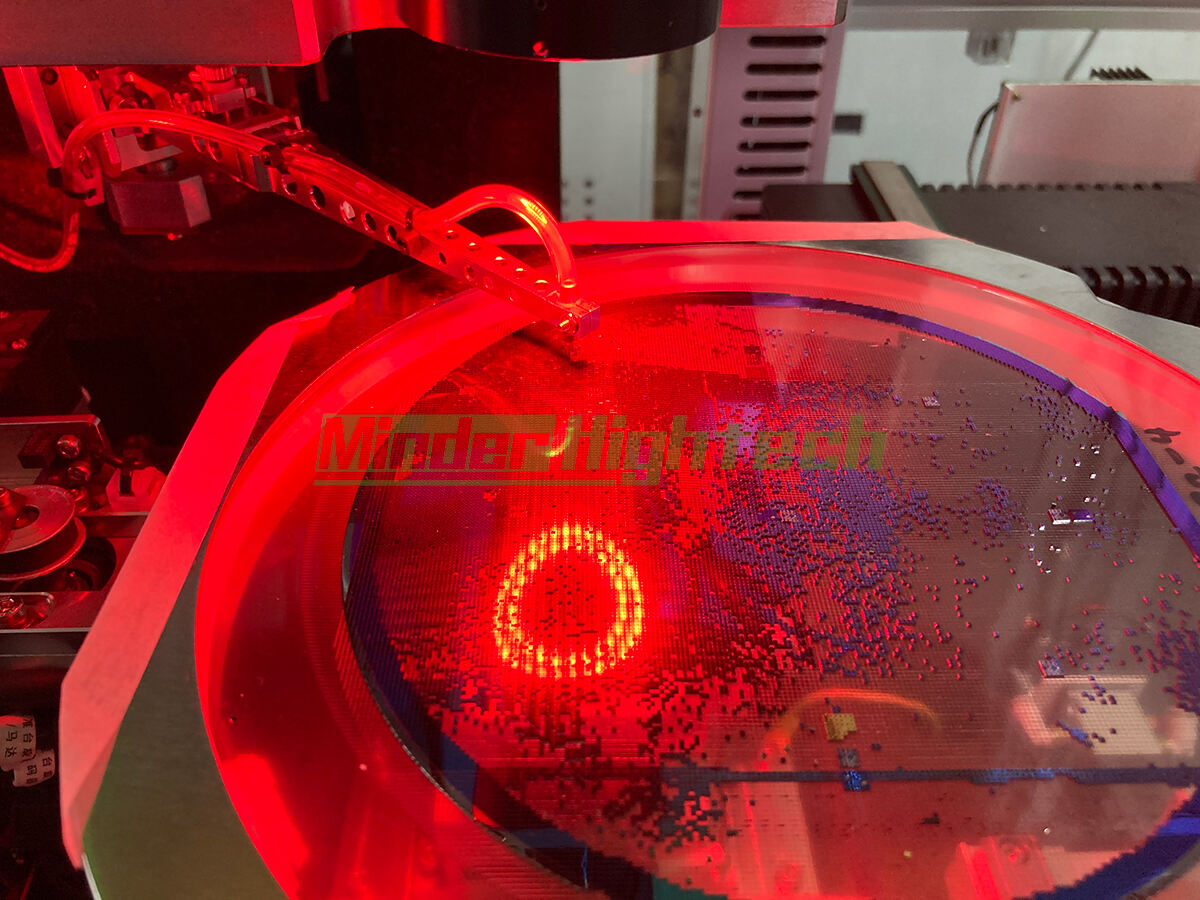

Die dimension |

5mil*5mil-100mil*100mil |

Wafer dimension |

6inch |

Picking up range |

4.5inch |

Bonding force |

25g-35g |

Multi wafer ring design |

4 wafer ring |

Die type |

R/G/B 3type |

Bonding arm |

90degree rotary |

Motor |

AC servomotor |

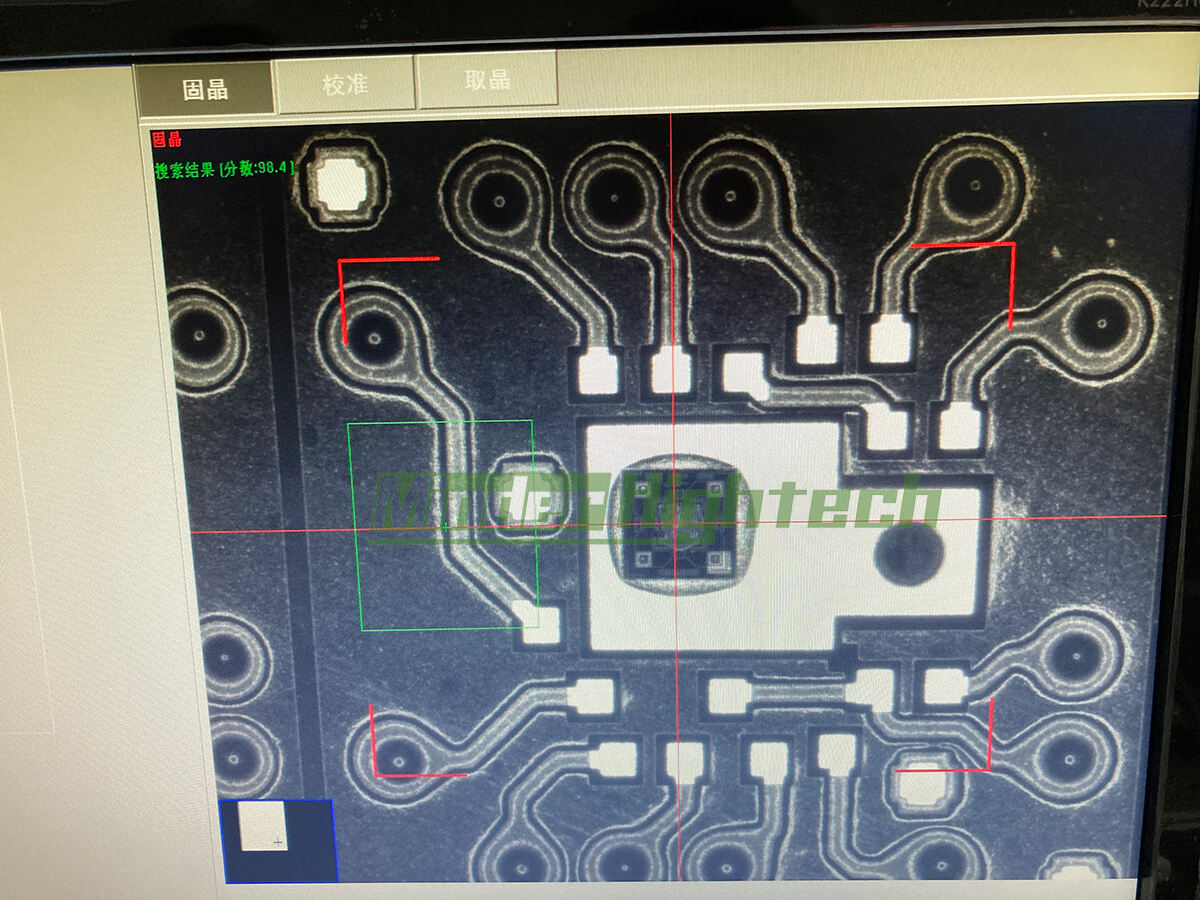

Image recognition system |

||

Method |

256 gray scale |

|

Check |

ink dot, chipping die, crack die |

|

Display screen |

17inch LCD 1024*768 |

|

Accuracy |

1.56um-8.93um |

|

Optics magnification |

0.7X-4.5X |

|

Bonding cycle |

120ms |

Number of program |

100 |

Max die number on one substrate |

1024 |

Die lost check method |

vacuum sensor test |

Bonding cycle |

180ms |

Glue dispensing |

1025-0.45mm |

Die lost check method |

vacuum sensor test |

Input voltage |

220V |

Air source |

min.6BAR,70L/min |

Vacuum source |

600mmHG |

Power |

1.8kw |

Dimension |

1310*1265*1777mm |

Weight |

680kg |

FAQ

Q: How to buy your products? A: We have some products in stock, you can take away the products after you arrange the payment;

If we don’t have the products in stock you want, we will start production once getting the payment.

Q: What’s the warranty for the products? A: The free warranty is one year from the date of commissioning qualified.

Q: Can we visit your factory? A: Of course, welcome to visit our factory if you come to China.

Q: How long is the validity of quotation? A: Generally, our price is valid within one month from the date of quotation. The price will be adjusted appropriately as the price fluctuation of raw material in the market.

Q: What’s the production date after we confirm the order? A: This depends on the quantity. Normally, for the mass production, we need about one week to finish the production.

If you're in the semiconductor industry, you know how crucial it is to have high-quality machines to assemble and package your devices. That's where Minder-High-tech comes in with their semiconductor IC to package surface substrate die attach machine, or die bonder, which is the perfect solution for reliable and efficient die bonding.

Made to bond the semiconductor IC potato chips to the surface regarding the substrate with simplicity. Works by aligning and placing the die onto the target substrate, positioning it accurately, and then bonding it making use of temperature, pressure, and energy is ultra-sonic. Using this machine, you will achieve a high-yield and bonding is reliable, even when dealing with smallest die sizes.

One for the standout features is its Surface Mounting Technology (SMT) process, which enables you to bond components that range from small to large. The Minder-High-tech machine is additionally equipped having a die pick-and-place station that ensures each die is positioned on the substrate exactly, making every bond reliable and strong. Additionally, the equipment's vision system permits accurate and alignment is fast ensuring your semiconductors are correctly placed before bonding.

Not hard to utilize. Its automatic controls and software are user-friendly operators to load and unload the die autonomously, freeing up more time and allowing for consistent manufacturing. This method is great for small to production is medium and prototyping, since well as for people who need certainly to create semiconductors with tight tolerances.

Installing and maintaining this is effortless, rendering it an addition is excellent your existing manufacturing processes. Its robust develop quality also helps it be an investment is reliable your company operations.

The Minder-High-tech semiconductor IC to package surface substrate die attach machine is an excellent option for a wide range of semiconductor manufacturing needs. Plus, with its brand name behind it, you know you're getting a product manufactured to the highest quality standards.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved