MDLB-MC200

Photomask cleaner

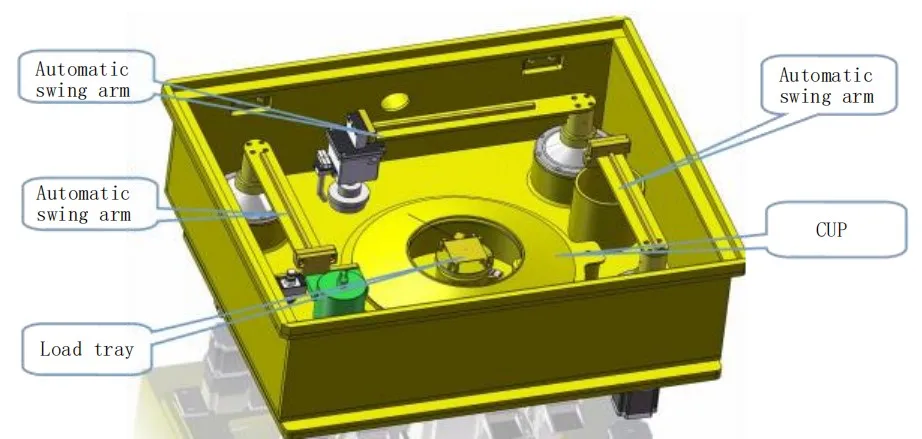

Cleaning unit:

The cleaning chamber is processed with corrosion-resistant materials, which have a smooth surface and are easy to clean. There is a waste discharge port at the bottom of the inner cavity, which utilizes gravity to allow waste liquid to be discharged into the factory waste discharge pipeline. There is a suction port inside the cavity, which can timely extract the atmosphere from the cavity. Equipped with 3 automatic swing arms, it can achieve automatic cleaning.

Configuration parameter table:

|

No. |

Project |

Specifications |

Remarks |

|

1 |

Equipment Overview |

Device Name: Photomask Cleaner |

|

|

Equipment model: MDLB-MC200 |

|

||

|

Overall dimensions (approximately): 1300mm (W) * 1000mm (D) * 1950mm (H) |

|

||

|

Whole machine weight (approximately): 300KG |

|

||

|

Operating table height: 900 ± 50mm |

|

||

|

Substrate size specifications: suitable for 2/4/5/6/8 inch square mask plates |

|

||

|

Process flow: manual wafer placement → cleaning (brush, cleaning solution → high-pressure water → megasonic water → deionized water → nitrogen gas drying) → manual wafer removal |

|

||

|

Equipment type: semi-automatic, manual loading and unloading |

|

||

|

2 |

Equipment construction |

Shell: stainless steel, smooth, corrosion-resistant, easy to clean |

|

|

Cleaning chamber: PP, smooth, corrosion-resistant, easy to clean |

|

||

|

Pipeline: PU/PFA matching pipeline is used |

|

||

|

Work lighting: anti-corrosion yellow light lighting |

|

||

|

Door opening style: Double door with door opening alarm function |

|

||

|

Touch screen: 10 inch full-color touch screen * 1 |

|

||

|

FFU: Class 100 |

|

||

|

Leak proof bottom support: available |

|

||

|

3 |

High precision servo motor |

Quantity: 1 |

|

|

Speed: -3000~3000rpm |

Empty load |

||

|

Maximum acceleration of spindle rotation: 3000rpm/S |

Empty load |

||

|

Speed accuracy: ± 1rpm (50rpm~3000rpm) |

|

||

|

Speed resolution: 1rpm |

|

||

|

4 |

Automatic swing arm |

Quantity: 3 |

|

|

Swing arm speed: 1~30 °/S |

|

||

|

5 |

Cleaning unit |

Cleaning swing arm: 1 channel of deionized water, 1 channel of nitrogen gas Megasonic Arm: 1 Megasonic, 1 High Pressure Water Brush arm: 1 brush, 1 water, 1 cleaning solution |

|

|

Cleaning method: automatic cleaning |

|

||

|

Deionized water suction function: available |

|

||

|

Backwash (deionized water): 1 route |

|

||

|

Supply method: Cleaning solution: Diaphragm pump Deionized water: supplied directly by the factory |

|

||

|

Pressure tank with liquid level detection |

|

||

|

6 |

Brush brush |

Quantity: 1 (with self-cleaning function) |

|

|

Speed: up to 1000rpm, adjustable speed |

|

||

|

Height manually adjustable |

|

||

|

7 |

Load tray |

Quantity: 5 |

|

|

Material: PPS+stainless steel |

|

||

|

Size: Suitable for 2/4/5/6/8 inch square mask plates |

|

||

|

Substrate fixing method: Claw fixing method |

|

||

|

8 |

Control system |

Control system: using PLC control |

|

|

Program: 100 groups, each group consisting of 100 steps, with a maximum single step time of 3000.0 seconds Resolution: 0.1S |

|

||

|

The program can be saved, called, modified, and deleted |

|

||

|

Set encryption permissions: for device operators, technicians, administrators, and manufacturers respectively |

|

||

|

Signal tower type: red, yellow, green 3 colors |

|

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved