PLASMA source | RF | ||

Power | ICP | _ | |

BIAS | 1000W(option) | ||

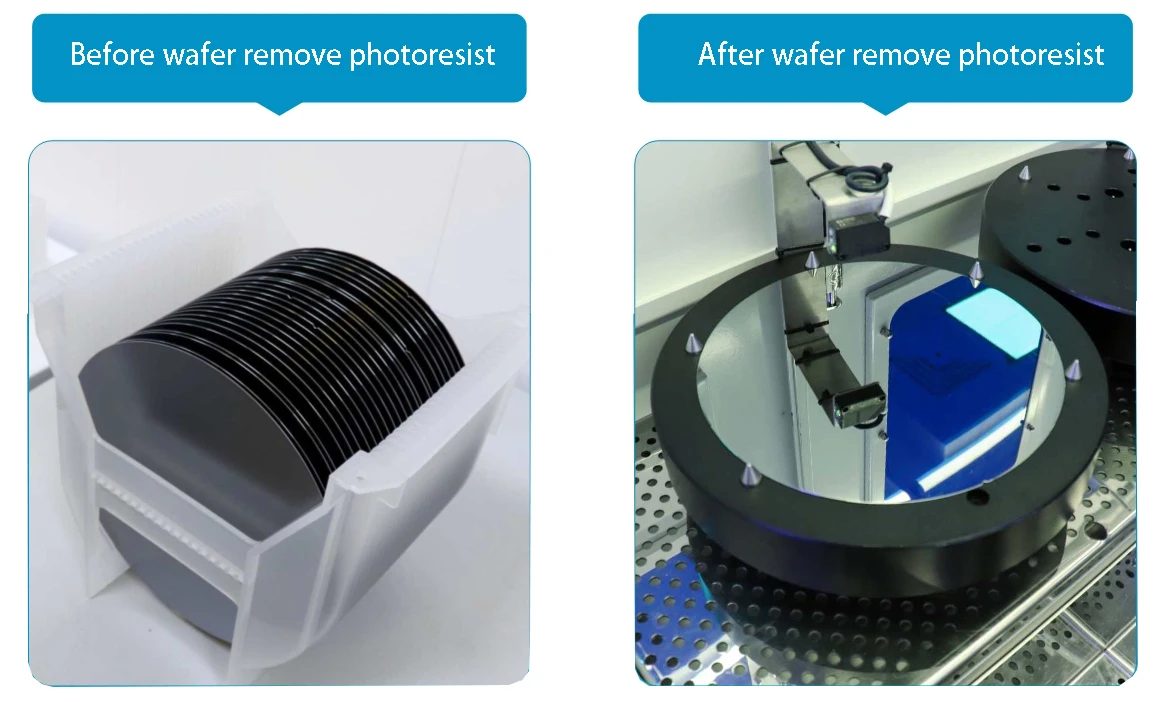

Applicable scope | 4~8 inch | ||

Single processing slice count | 1 | ||

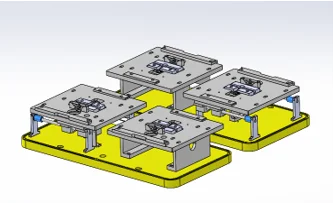

Appearance dimensions | 850mmx900mmx1850mm | ||

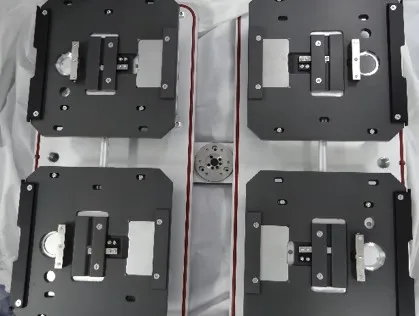

System control | PLC | ||

Automation level | Manual | ||

Hardware Capability | ||

Uptime/Available time | ≧95% | |

Mean time to clean (MTTC) | ≦6 hours | |

Mean time to repair(MTTR) | ≦4 hours | |

Mean time between failures(MTBF) | ≧350 hours | |

Mean time between assistant(MTBA) | ≧24 hours | |

Mean wafer between broken(MWBB) | ≦1 in 10,000 wafers | |

Heating plate control | 50-250° | |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved