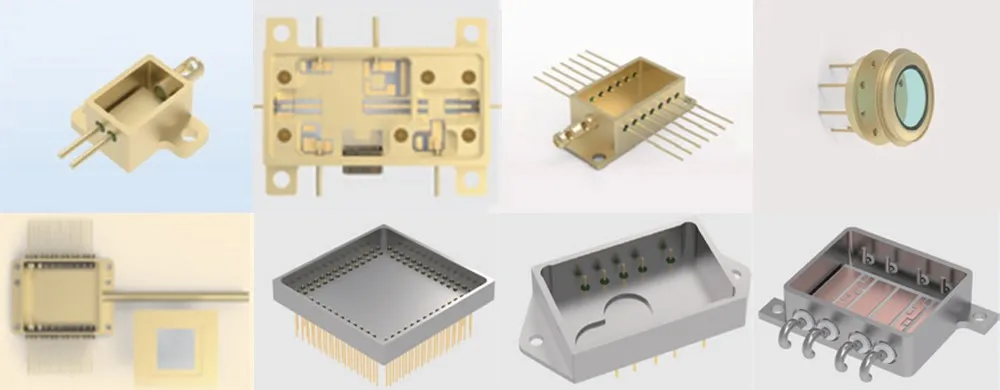

Our company's MDNY-YAYD160 series helium/fluorine oil pressure equipment, combined with helium mass spectrometer leak detector and heavy fluorine oil heating leak detector, is an automated helium/fluorine oil pressure equipment designed for fine and coarse inspection of electronic components such as integrated circuits, semiconductor devices, and electronic products.

Fluorine oil/helium gas has excellent dielectric properties, chemical inertness, electrical insulation, and high and low

temperature resistance. It is non corrosive to electronic components and does not affect their various parameters. Make it an ideal leak detection medium for electronic component leak testing.

The principle of helium pressurization fine inspection: First, place the original device in a sealed container that can be

pressurized, and pressurize the component with helium for a certain period of time. If there is a leak in the component, helium gas is forced into the inner cavity. Then remove the tested component and place it in the detection box of the helium mass spectrometer leak detector for vacuum leak detection. If there is a leak in the component, the helium gas entering its inner cavity will overflow into the leak detector, and the leak detector will display the leakage rate.

The principle of fluorine oil leak detection method is that the molecules of the leak detection medium are small, so even small leaks can pass through. If there are leaks in the device, light fluorine oil/helium gas will enter the device under pressure during pressurization. Due to the boiling point temperature of light fluorine oil being about 45.7 ℃, when placed in heavy fluorine oil at a temperature of 125 ℃, the light fluorine oil quickly vaporizes, causing a rapid increase in pressure inside the component cavity. The gas inside the cavity will emerge from the leak, resulting in the appearance of bubbles in high boiling fluorine oil.

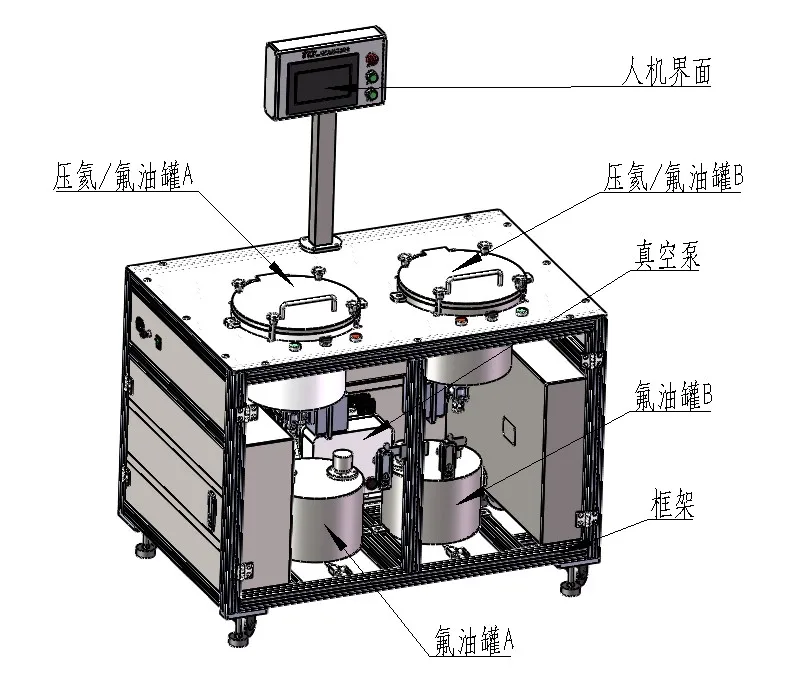

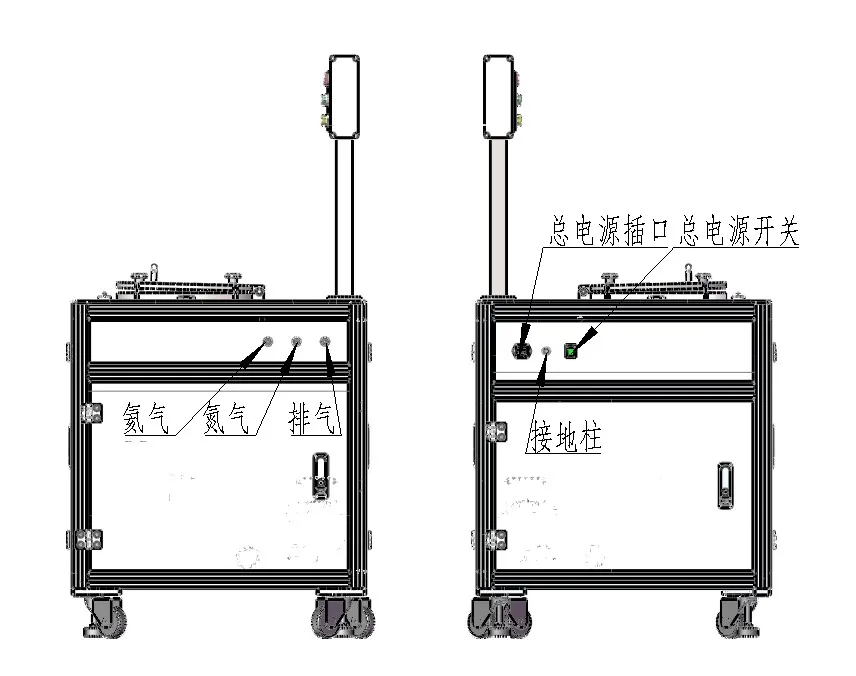

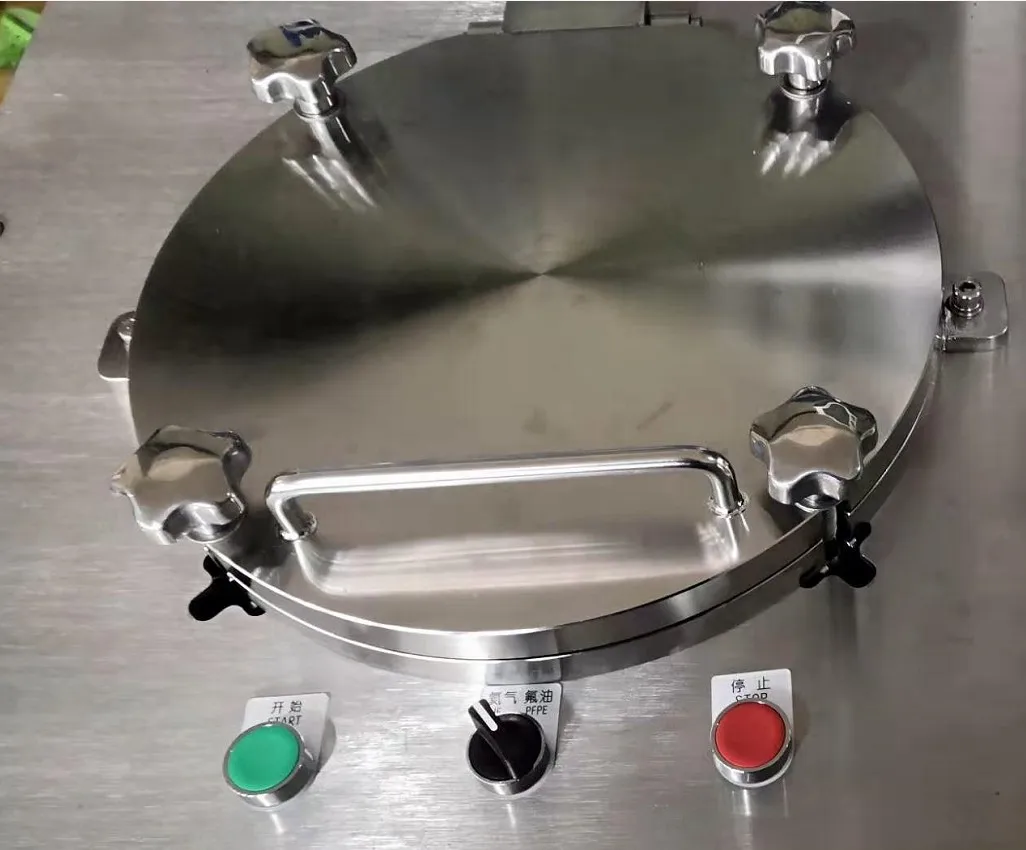

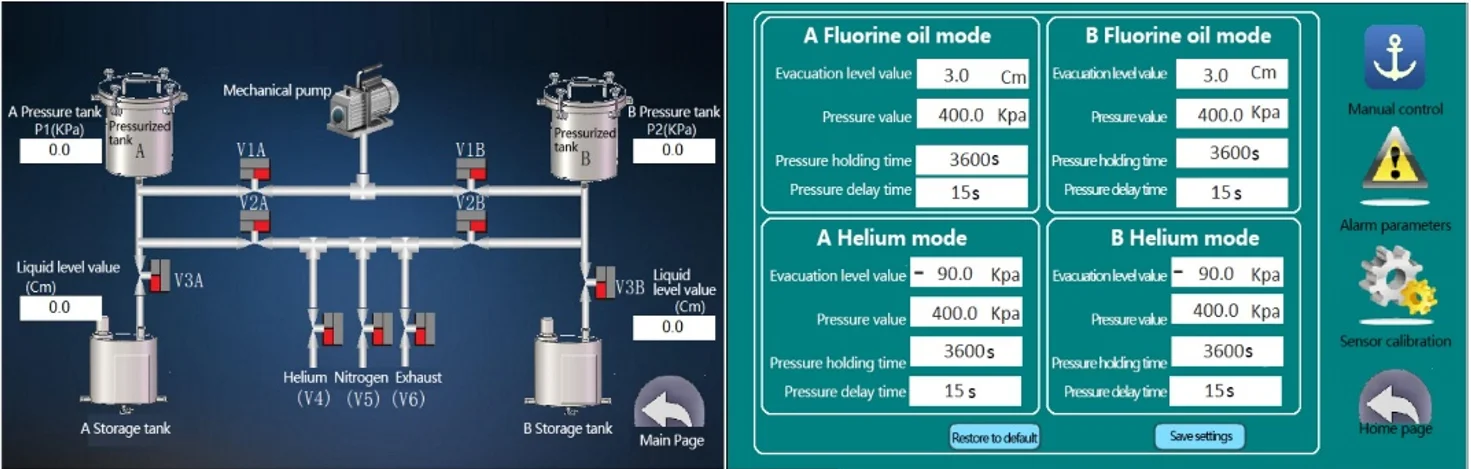

All valve bodies of this equipment are controlled by electric ball valves, which can be operated with one click through a PLC based control system. And equipped with a touch screen, it can constantly observe the pressure and liquid level inside the pressurized fluorine oil/helium tank.

This device has a compact overall structure, is easy to move, is easy to operate, has high detection efficiency, and is long-term safe and reliable. The appearance of the equipment is shown in the diagram: