Project |

Content |

Product Type |

6",8",12" wafer, 2.5D/3D packaging |

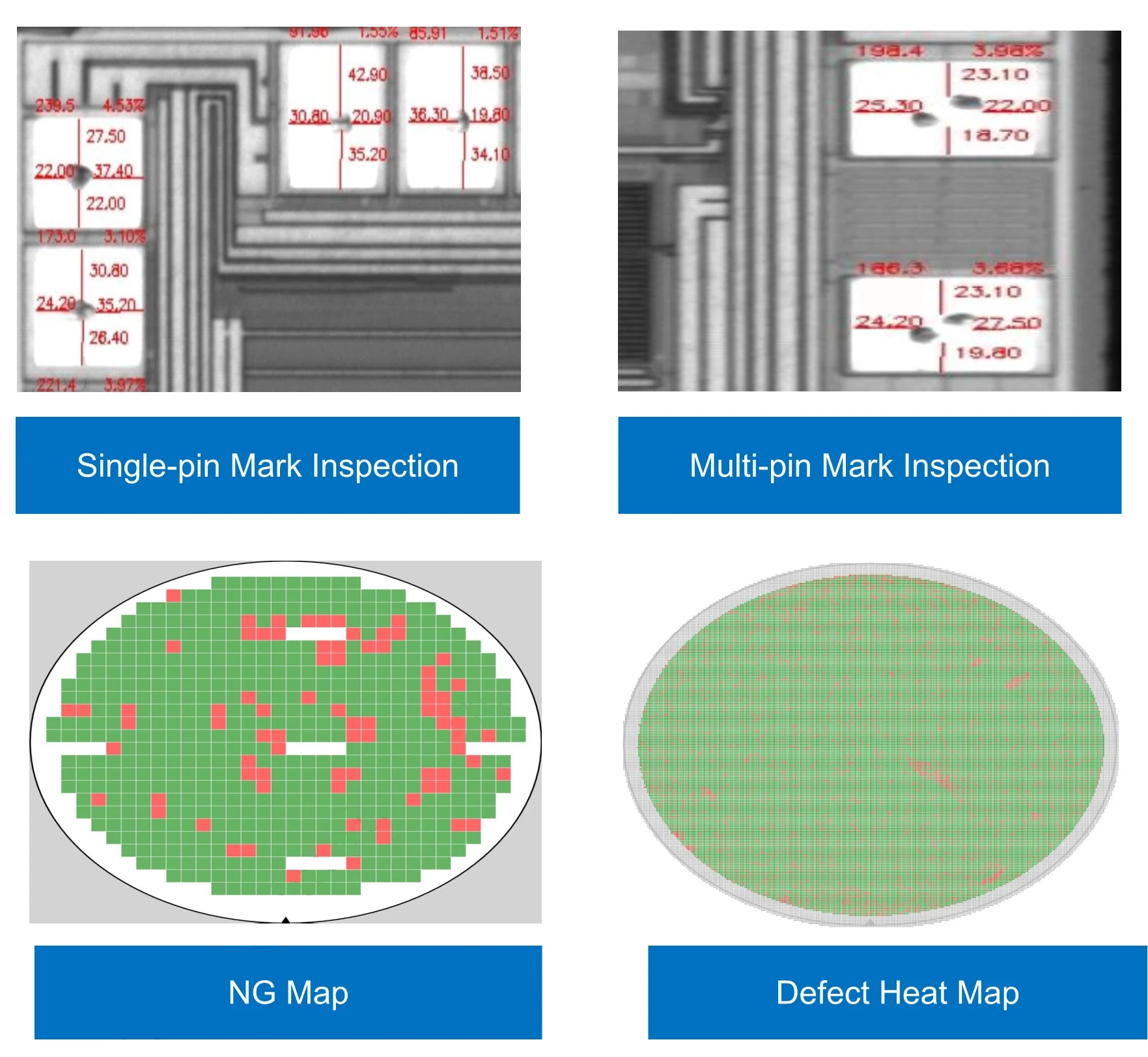

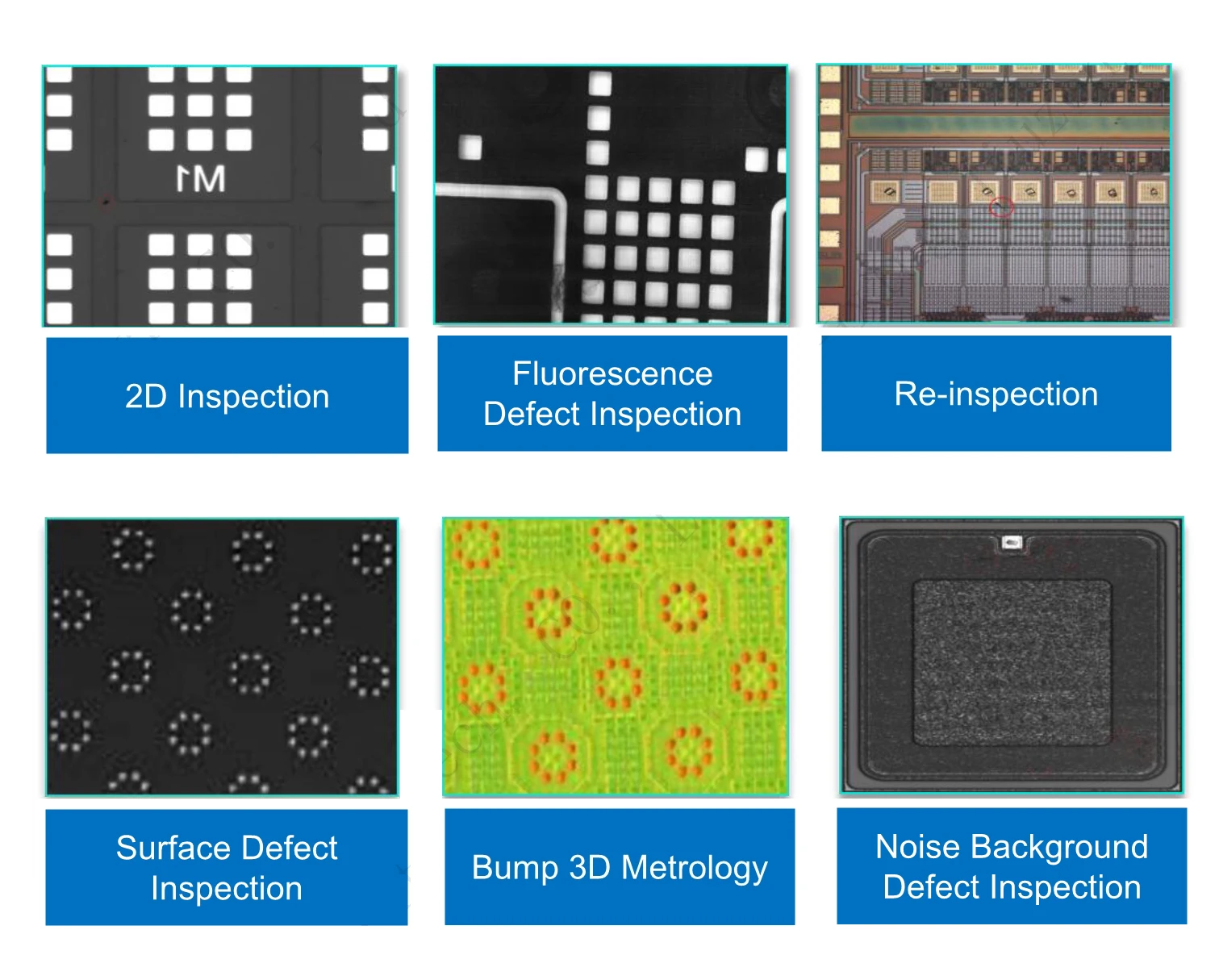

2D Inspection Items |

Foreign objects, residual glue, particles, scratches, cracks, contamination, CP deviation, excessive needle marks, etc. |

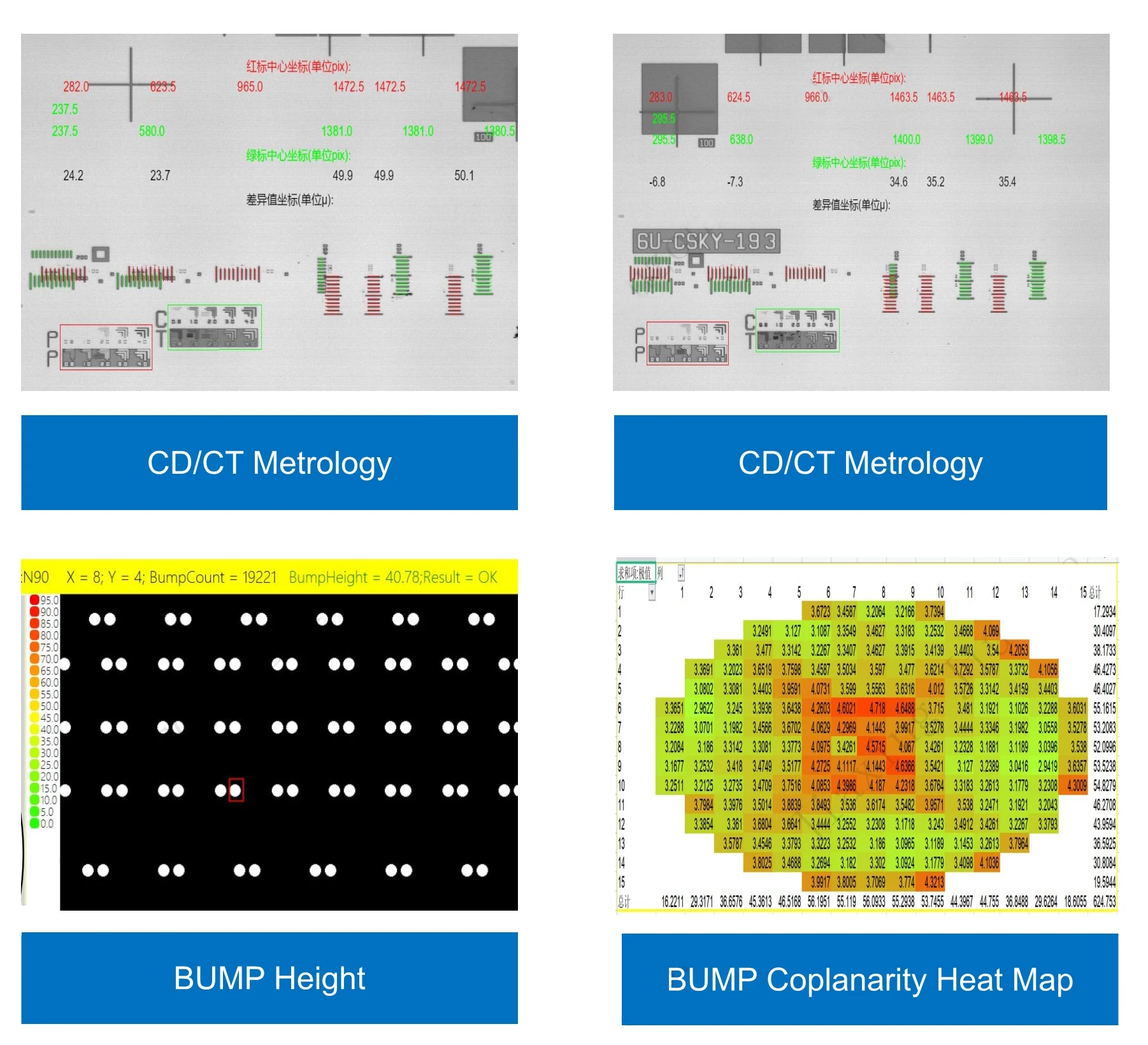

2D Metrology |

Bump diameter, needle mark coordinates, RDL and TSV metrology, etc. |

3D Inspection Project |

Bump height, Bump coplanality |

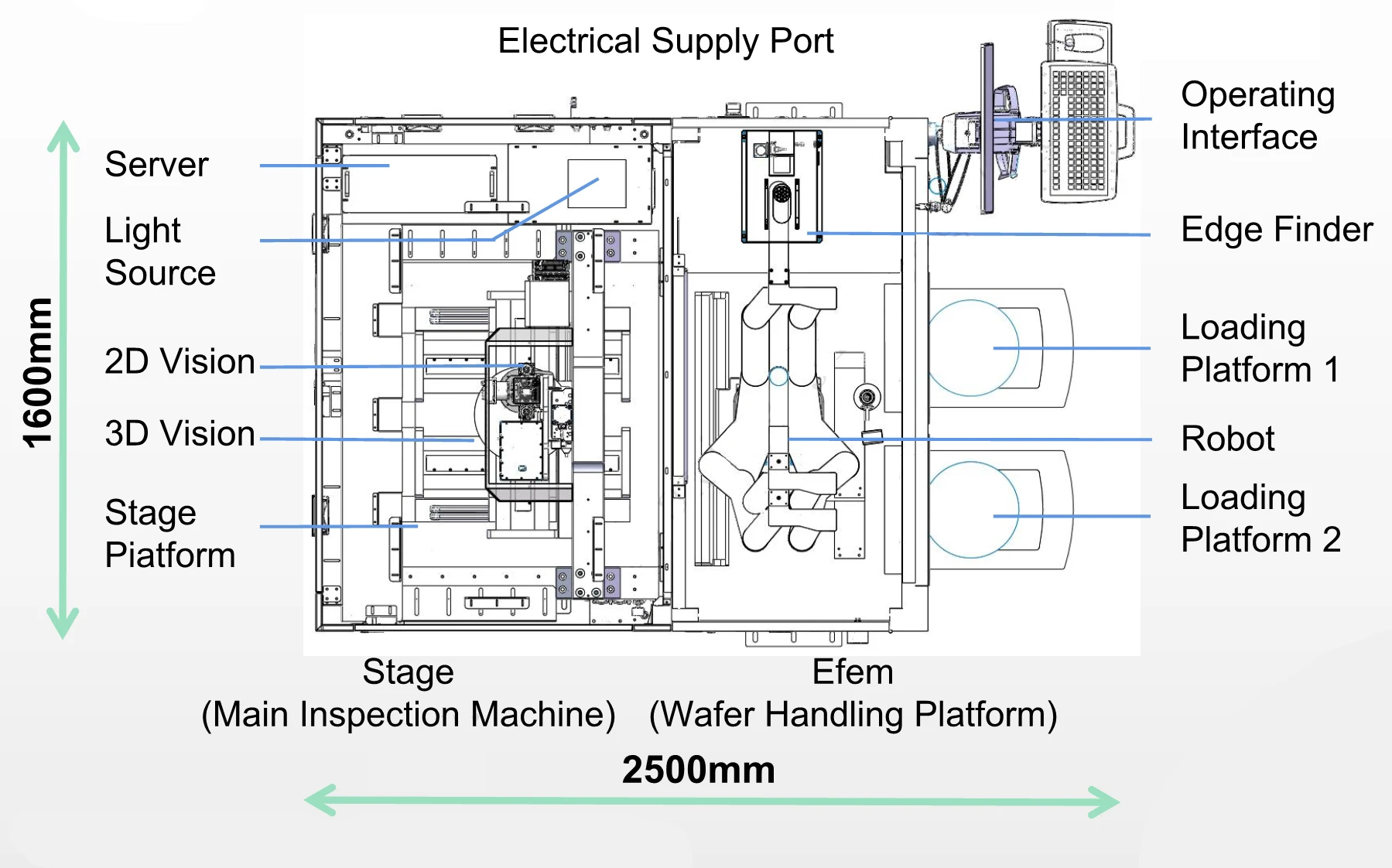

Cassette &Transmission Method |

8"SMIF , 12" FOUP or combination |

Lens and Resolution |

2x(2.75um)13.5x(1.57um)5x(1.1um)17.5x(0.73um)110x(0.55um) |

Precision |

0.55um/pixel |

Optional and Customized |

Double sided OCR,3D module, supported by E84 |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved