structure size |

||

Basic frame |

1260*1160*1200mm |

|

Maximum height of base |

90mm |

|

Observation window |

include |

|

Weight |

350KG |

|

Vacuum system |

||

Vacuum pump |

Vacuum pump with oil pollution filtering device optional dry pump |

|

Vacuum level |

Up to 10Pa |

|

Vacuum configuration |

1. Vacuum pump 2. Electric valve |

|

Pumping speed control |

The pumping speed of the vacuum pump can be set by the host computer software |

|

Pneumatic system |

||

Process gas |

N2, N2 / H2 (95% / 5%), HCOOH |

|

First gas path |

Nitrogen/nitrogen-hydrogen mixture (95%/5%) |

|

Second gas path |

HCOOH |

|

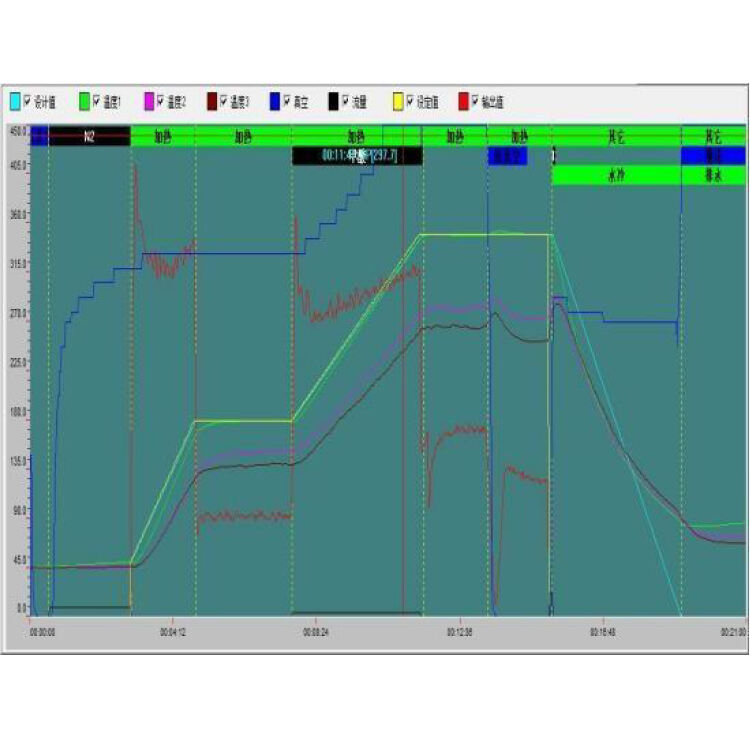

Heating and cooling system |

||

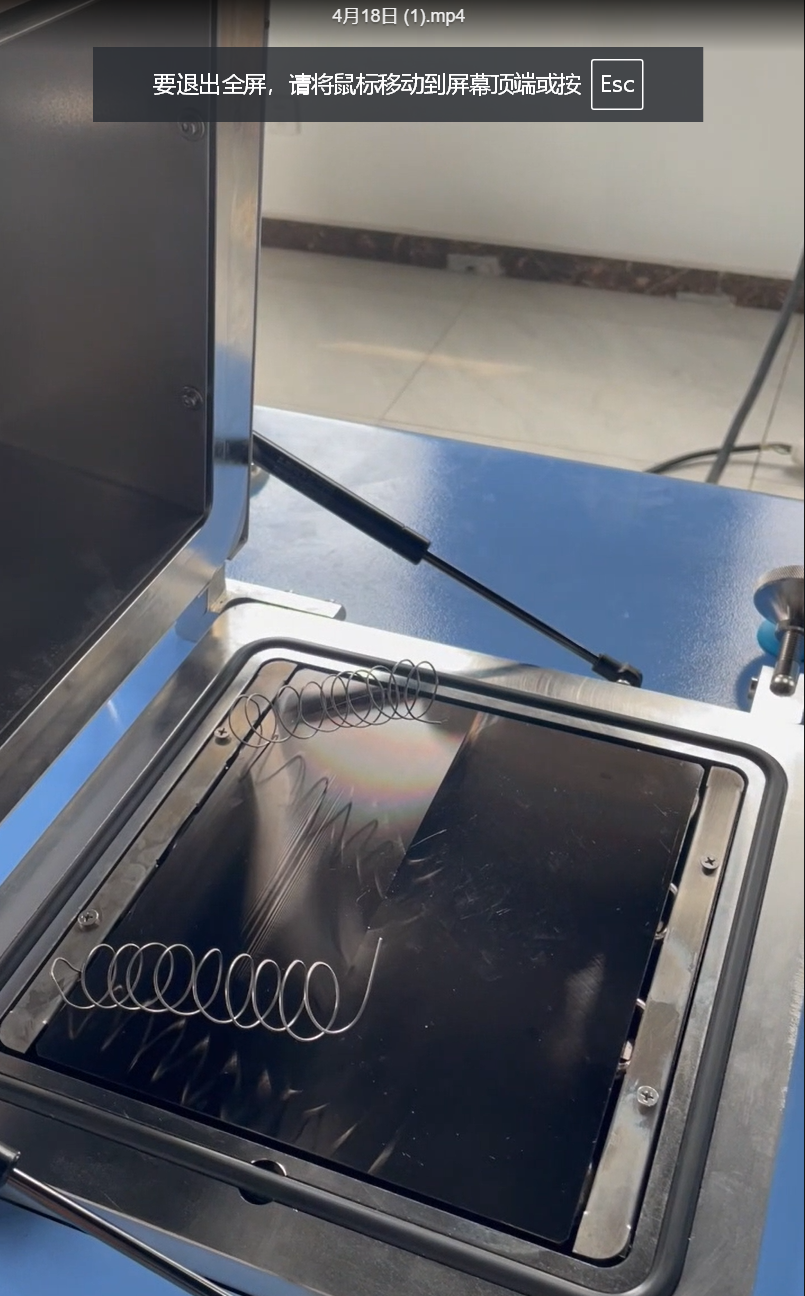

Heating method |

Radiant heating, contact conduction, heating rate 150℃/min |

|

Cooling method |

Contact cooling, the maximum cooling rate is 120℃/min |

|

Hot plate material |

copper alloy, thermal conductivity: ≥200W/m·℃ |

|

Heating size |

420*320mm |

|

Heating device |

Heating device: the vacuum heating tube is used; the temperature is collected by the Siemens PLC module, and the PID control is controlled by the host computer Advantech. |

|

Temperature range |

Max 450℃ |

|

Power requirements |

380V, 50/60HZ three-phase, maximum 40A |

|

Control System |

Siemens PLC + IPC |

|

Equipment power |

||

Coolant |

Antifreeze or distilled water ≤20℃ |

|

Pressure: |

0.2~0.4Mpa |

|

coolant flow rate |

>100L/min |

|

Water tank water capacity |

≥60L |

|

Inlet water temperature |

≤20℃ |

|

Air source |

0.4MPa≤air pressure≤0.7MPa |

|

Power supply |

single-phase three-wire system 220V, 50Hz |

|

Voltage fluctuation range |

single phase 200~230V |

|

Frequency fluctuation range |

50HZ±1HZ |

|

Equipment power consumption |

about 18KW; grounding resistance ≤4Ω; |

|

Host system |

including vacuum chamber,main frame, control hardware and software |

Nitrogen pipeline |

Nitrogen or nitrogen/hydrogen mixture can be used as process gas |

Formic acid pipeline |

Bringing formic acid into the process chamber via nitrogen |

Water cooling pipeline |

cooling the upper cover, lower cavity and heating plate |

Water cooler |

Provide continuous water cooling supply to equipment |

Vacuum pump |

Vacuum pump system with oil mist filtration |

Temperature |

10~35℃ |

|

Relative humidity |

≤75% |

|

The environment around the equipment is clean and tidy, the air is clean, and there should be no dust or gas that can cause corrosion of electrical appliances and other metal surfaces or cause conduction between metals. |

||

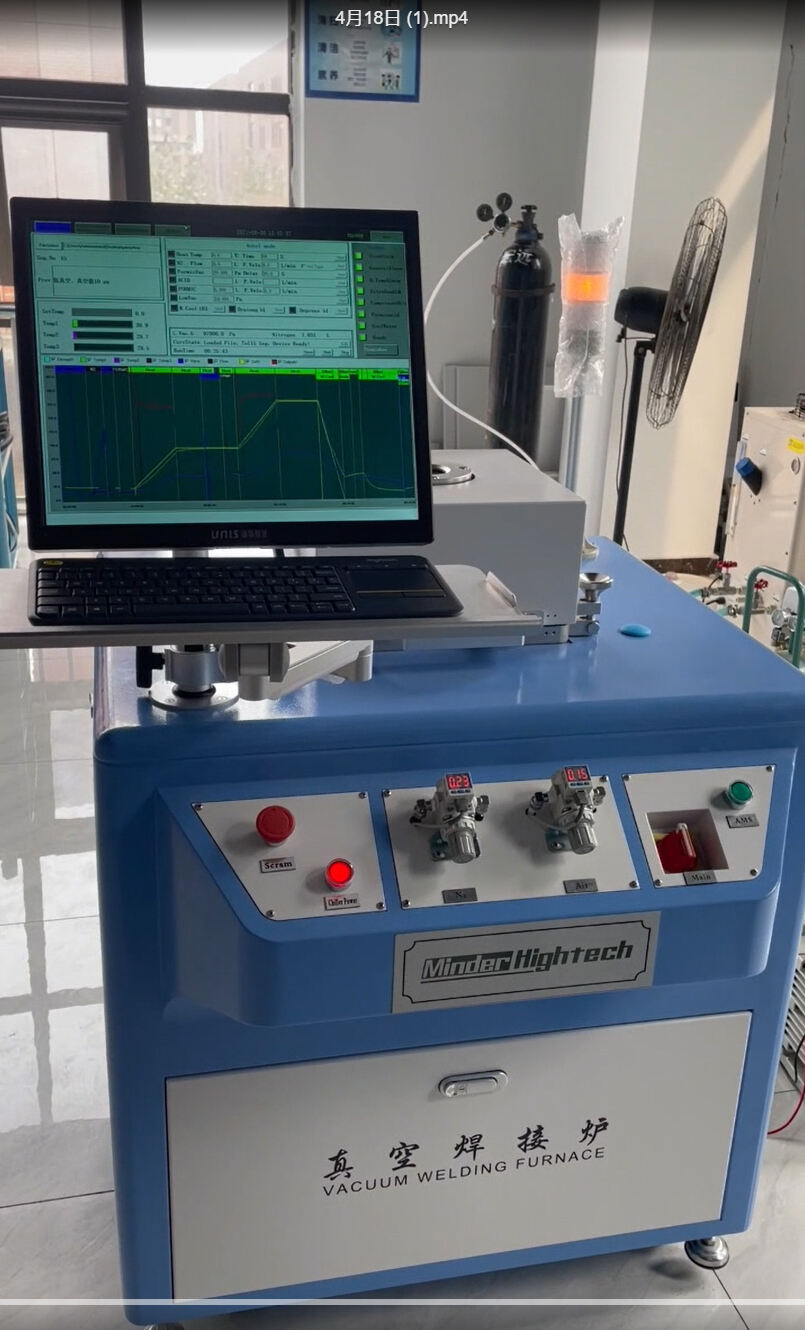

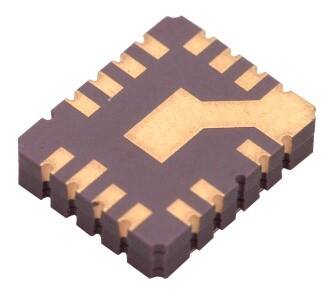

The Minder-Hightech Semiconductor MDVES400 Single Cavity Vacuum Reflow Oven is the ideal item for people looking for perfect soldering outcomes. The oven is specifically developed towards deal with IGBT and MEMS vacuum soldering procedures, guaranteeing outcomes that surpass market requirements.

Geared up along with advanced vacuum innovation, which implies that every soldering treatment creates an outcome is spotless. The vacuum cleaner innovation assists towards eliminate oxygen coming from efficiently the soldering atmosphere, which as a result visits oxidation of the soldering products and semiconductor aspects, offering a guard coming from ecological contamination.

Includes a roomy cavity is single a durable building, guaranteeing that the cleanser and temperature level setups are enhanced for every single soldering procedure. The oven is developed towards reflow a variety is broad of kinds and styles while providing constant first-class outcomes.

Provides flexibility in procedure, allowing individuals towards control the temperature level setups in simply a range of 300 towards 500°C. The temperature level variety setups can be rapidly and quickly personalized towards suit private requests utilizing the programmable operator is temperature level.

Has a get in touch with is distinct ability, where soldering is carried out along with vacuum problems, practically getting rid of any type of variance in the soldering outcomes that may have been actually triggered by fuel bits created through the soldering procedure.

Has an energy-saving innovation, which guarantees very little energy usage while decreasing the cost of soldering and sustainability is enhancing. It is particularly created towards ensure durability and resilience because it truly is developed along with top quality products which can be appropriate for severe production environments.

Functions a user interface is easy to use is certainly not difficult towards run. A comprehensive individual handbook is roofed towards direct individuals on simply ways to run the oven, guaranteeing that individuals acquire a smooth and expertise is simple and easy.

If you are appearing for a vacuum soldering oven that creates high-grade soldering outcomes each time, the Minder-High-tech Semiconductor MDVES400 Single Cavity Vacuum Reflow Oven is the ideal option. Along with its own top-quality building, energy-saving innovation, and a variety of adjustable temperature level setups, it provides constant and remarkable soldering outcomes each time.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved