|

Configuration and performance

|

Processing size

|

φ160mm or φ150mm

|

||

|

Groove depth

|

≦4mm or customized

|

|||

|

Flatness of worktable

|

±0.005mm/150mm

|

|||

|

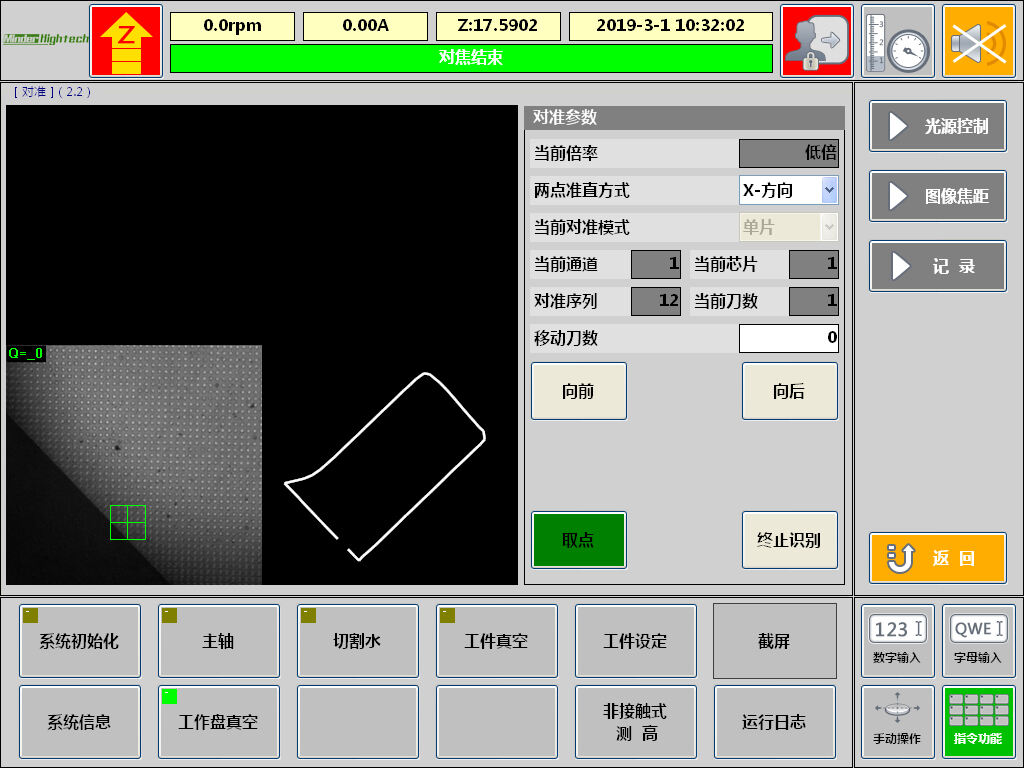

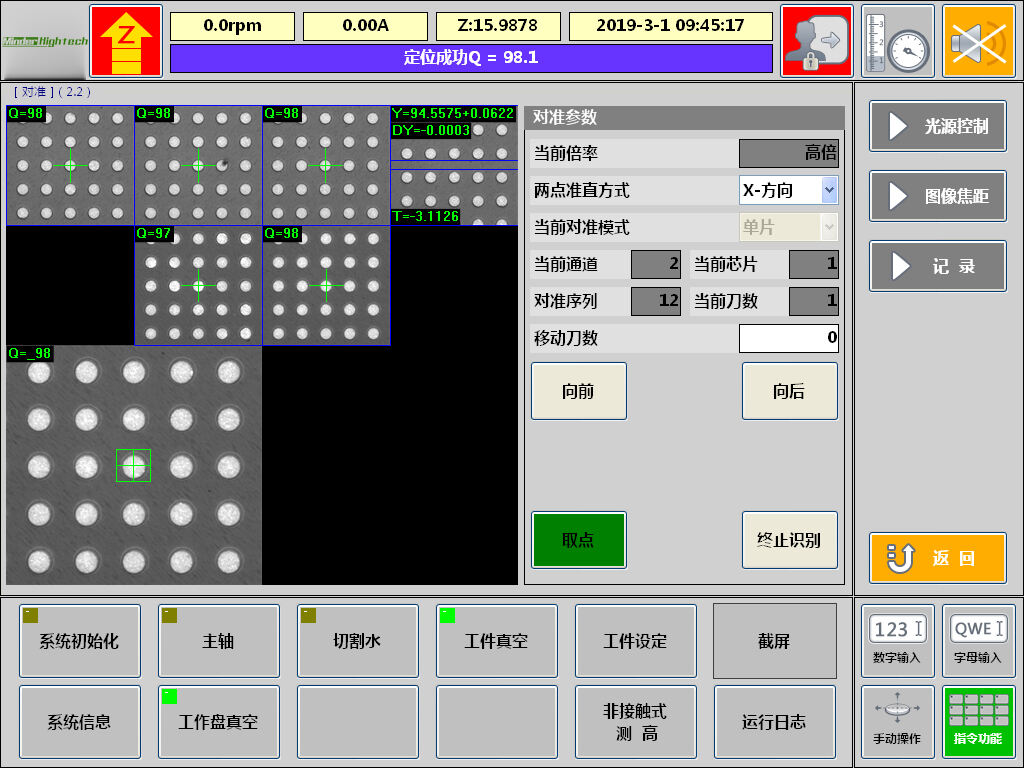

Alignment system

|

Dual lens, straight light﹢ring light

|

|||

|

Spindle

|

range of rotation

|

10000~50000rpm

|

||

|

Output Power

|

DC 1.5KW (2.4KW optional)

|

|||

|

X axis

|

Drive way servo

|

motor |

||

|

Workbench left and right stroke

|

240mm

|

|||

|

Stroke resolution

|

0.001mm

|

|||

|

Speed setting range

|

0.1~500mm/s

|

|||

|

Y axis

|

Drive way

|

Stepping motor ﹢ grating closed loop control system

|

||

|

Spindle back and forth stroke

|

170mm

|

|||

|

Stroke resolution

|

0.0001mm

|

|||

|

Single-step positioning accuracy

|

≦0.002mm/5mm

|

|||

|

Full positioning accuracy

|

≦0.004mm/170mm

|

|||

|

Z axis

|

Drive way

|

Stepper motor

|

||

|

Spindle up and down stroke

|

30mm

|

|||

|

Stroke resolution

|

0.0001mm

|

|||

|

Repeatability

|

0.001mm

|

|||

|

θ axis

|

Drive way

|

DD motor

|

||

|

Angle range

|

380º

|

|||

|

Angle resolution

|

0.0002º

|

|||

|

Basic specifications power

|

supply

|

Three-phase, AC380±5%, 3.0kVA

|

||

|

power consumption

|

0.6KW during processing (reference value)

|

|||

|

When warming up 0.4KW (reference value)

|

||||

|

Compressed air

|

Pressure 0.5~0.6Mpa, maximum consumption 220L/min

|

|||

|

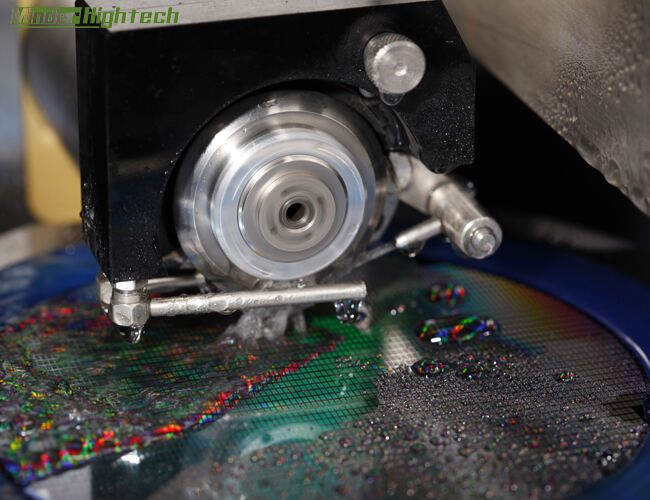

Cutting water

|

Pressure 0.2~0.3Mpa, maximum consumption 3.5L/min

|

|||

|

Cooling water

|

Pressure 0.2~0.3Mpa, maximum consumption 1.5L/min

|

|||

|

Exhaust volume

|

1.5m³/min (ANR)

|

|||

|

Dimensions W×D×H

|

580mm×850mm×1650mm

|

|||

|

weight

|

500kg

|

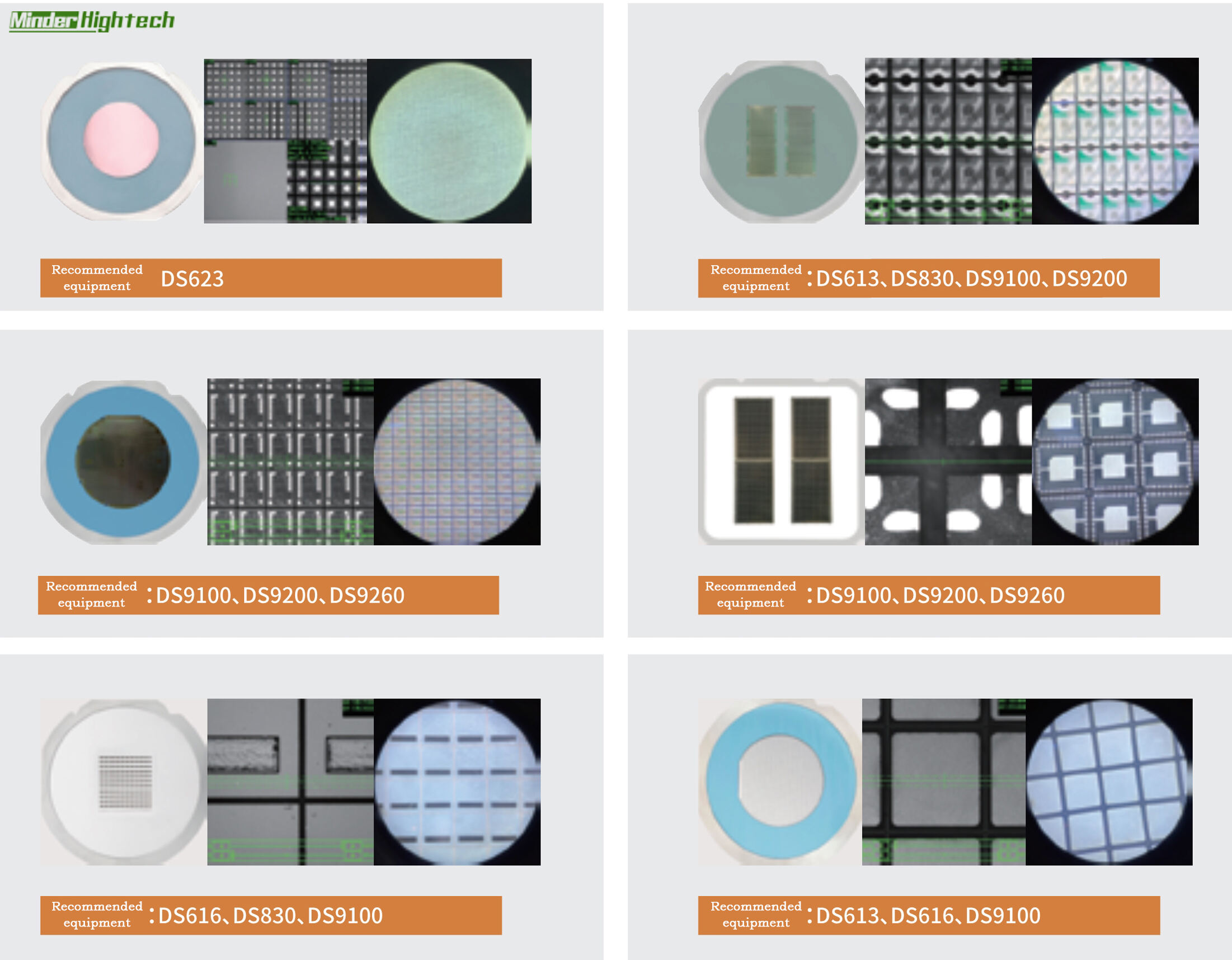

The Minder-Hightech High-Precision Cutting Machine is perfect for different markets as it provides an effective and precise service for cutting products easily. Geared up along with ingenious functions, this machine helps in reducing the empty cutting distance, therefore conserving manufacturing sets you back and opportunity.

The gadget consists of a high-precision cutting innovation implies precise cutting of products. Used through this allows for enhanced effectiveness and much a lot extra reduces that are precise. This implies the gadget can provide likewise much a lot extra styles that are complicated designs without any concession on precision.

Among the various reveals is its own ability towards acknowledge products accurately. This enables individuals produce styles that are elaborate different products easily. The gadget is ideal for cutting fabrics, natural leather, report, and rubber, among others. The revolutionary innovation is cutting enhance manufacturing effectiveness, enabling individuals produce elaborate styles at a quicker price.

Developed towards reduce the cutting distance is empty. This include helps in relieving manufacturing costs through reducing products that are ditch. The devices happen geared up along with a blade is fast can quickly puncture products along with precision. The blade is fast optimal efficiency through providing a constant rate, regardless of product density.

Ergonomic style and software application is easy to use it feasible for also beginner individuals towards run. The machine's cutting mattress is built along with a vacuum cleaner is professional-grade that assurances the product remains continuously in position throughout cutting. The cutting mattress likewise promotes a transition is fast enabling for quick modifications and modifications in cutting style.

Using this, you can just anticipate greater than accuracy cutting. The machine is developed for durability along with resilient products that guarantee its own durability. The aspects utilized in the building of the machine are concerning the high-top premium is greatest, therefore providing outstanding efficiency while enduring much a lot longer compared to most cutting devices in the market place. Buying the Minder-Hightech High-Precision Cutting Machine is a smart financial asset you can create for your business; it is certain towards provide far-reaching advantages for years to find.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved