|

Model

|

MD-SWBW4010

|

MD-SWBW2030

|

MD-SWBW2040

|

MD-SWBW2050

|

MD-SWBW2080

|

||||

|

Ultrasonic frequency

|

20KHz 40KHz

|

||||||||

|

Input

|

AC220V/50Hz

|

||||||||

|

Ultrasonic power

|

1000W

|

3000W

|

4000W

|

5000W

|

8000W

|

||||

|

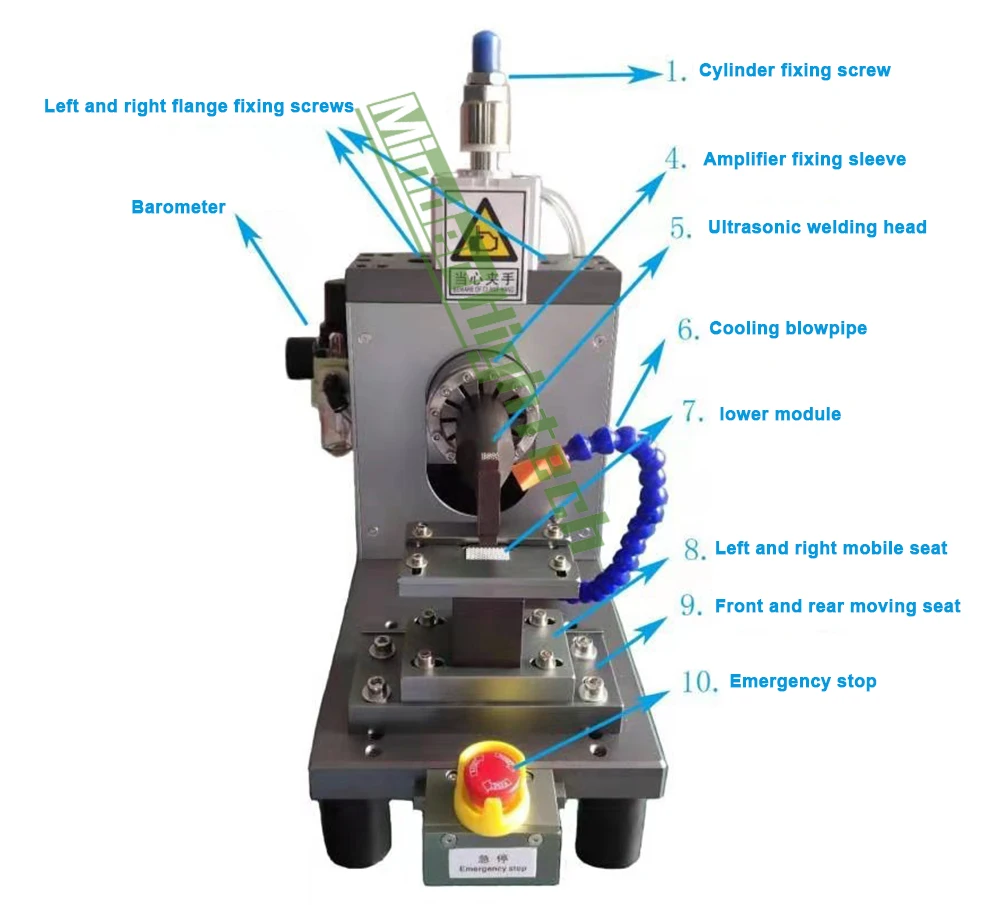

Air pressue

|

0.4MPa~0.6MPa

|

||||||||

|

Control

|

Time/energy

|

||||||||

|

Welding stroke

|

30mm

|

||||||||

|

Structure dimension

|

440*230*400mm

|

||||||||

|

Generator dimension

|

450*435*140mm

|

||||||||

|

Weight

|

60kg

|

65kg

|

65kg

|

70kg

|

100kg

|

||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved