Specification

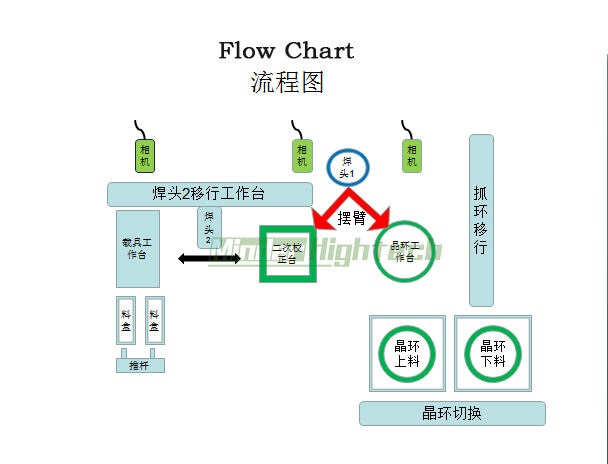

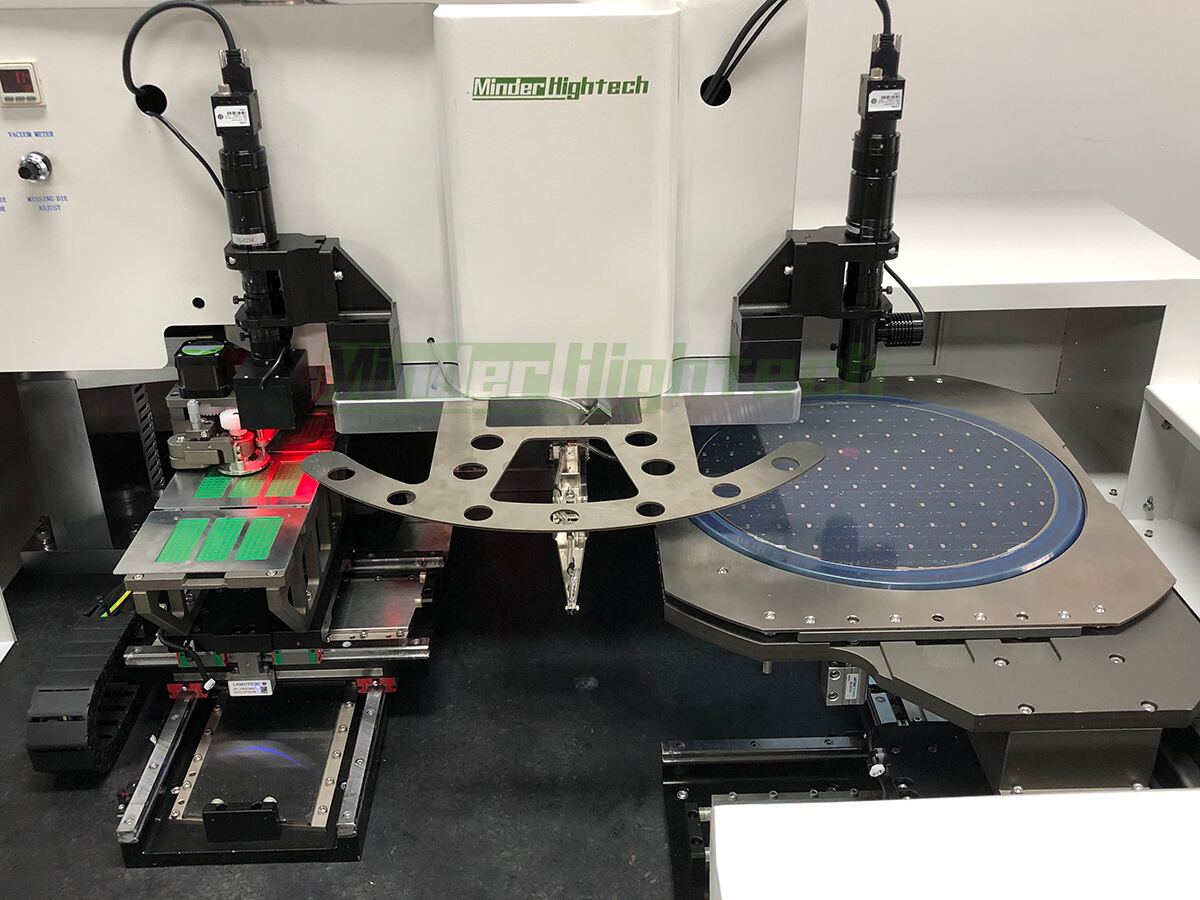

Specification| Bonding workstage | ||

| Load ability | 1 piece | |

| XY stroke | 10inch*6inch(working range 6inch*2inch) | |

| Accuracy | 0.2mil/5um | |

| Dual work stage can feed continuously |

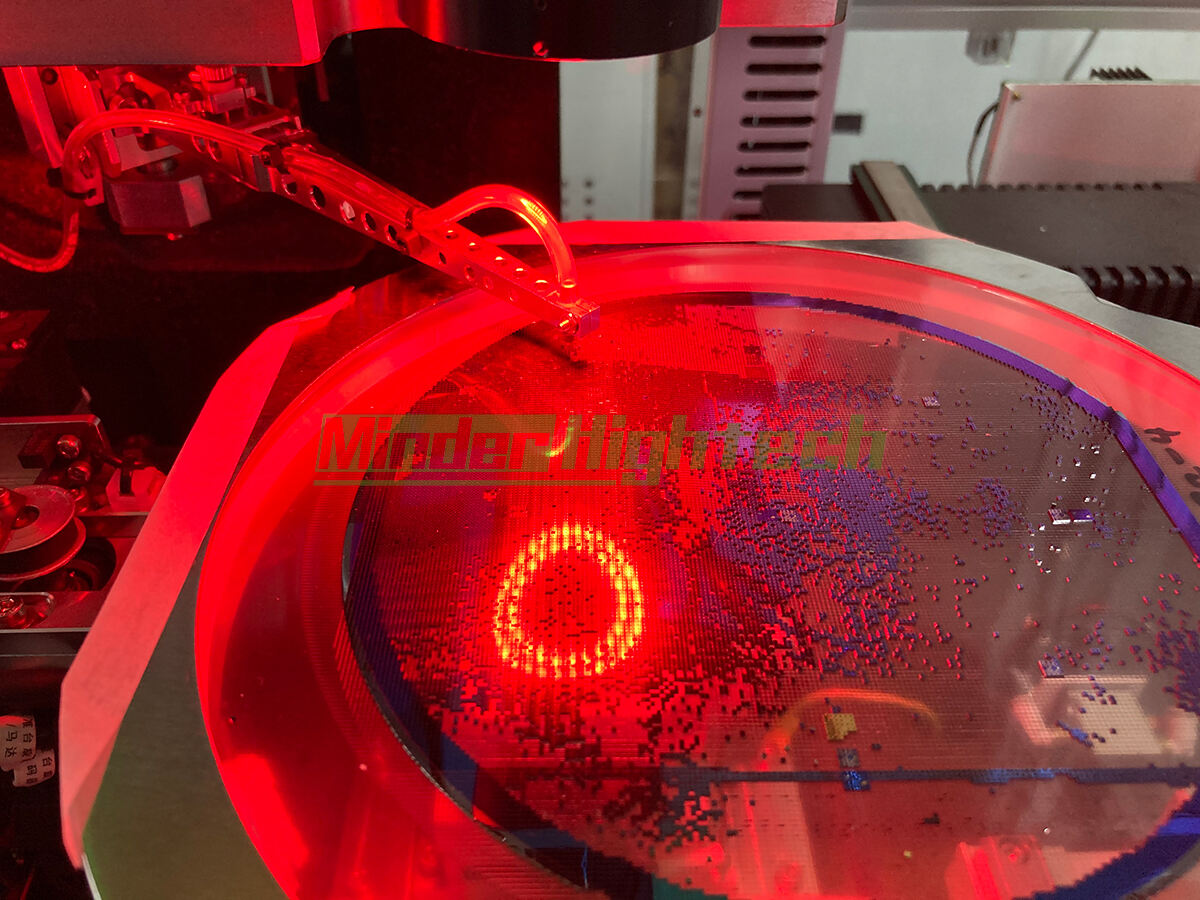

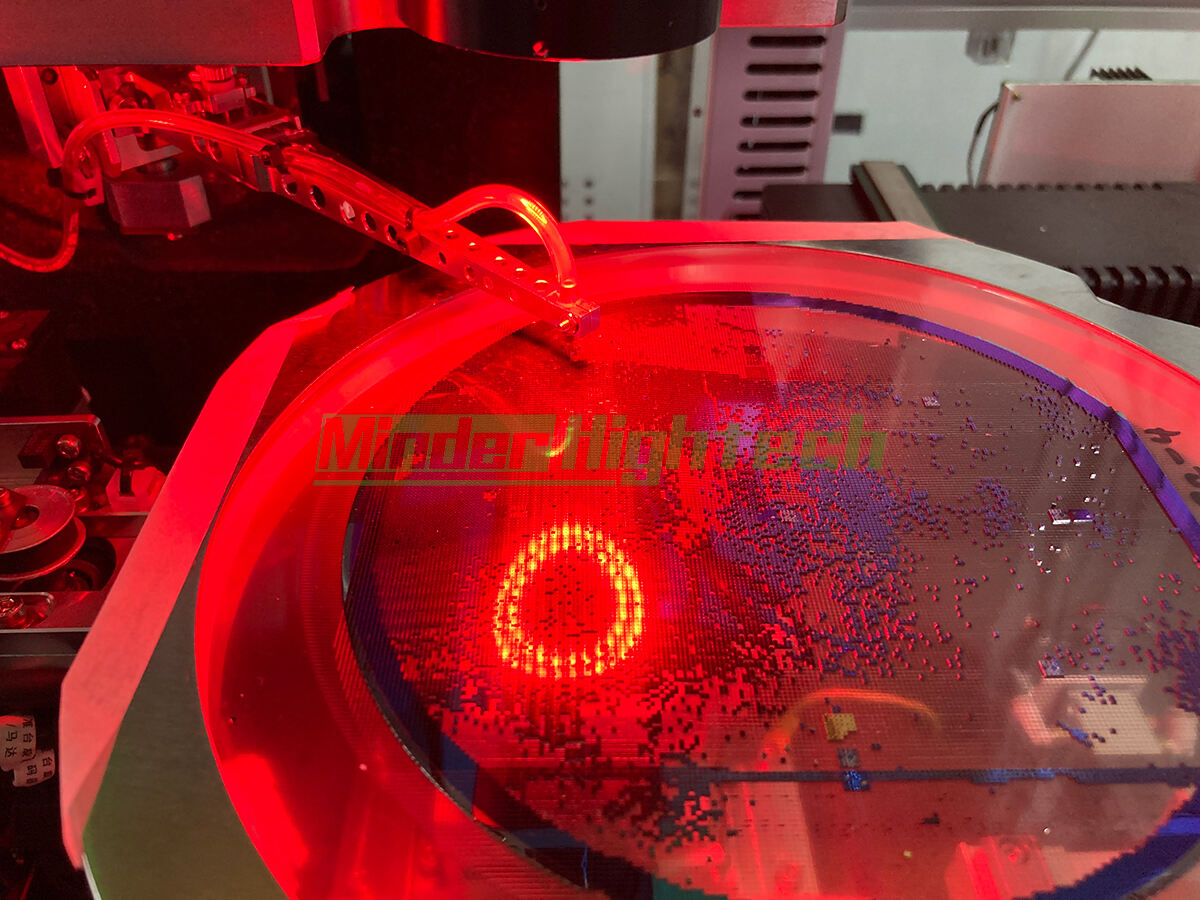

| Wafer workstage | ||

| XY travel stroke | 6inch*6inch | |

| Accuracy | 0.2mil/5um | |

| Wafer position accuracy | +-1.5mil | |

| Angle accuracy | +-3 degree |

| Die dimension | 5mil*5mil-100mil*100mil |

| Wafer dimension | 6inch |

| Picking up range | 4.5inch |

| Bonding force | 25g-35g |

| Multi wafer ring design | 4 wafer ring |

| Die type | R/G/B 3type |

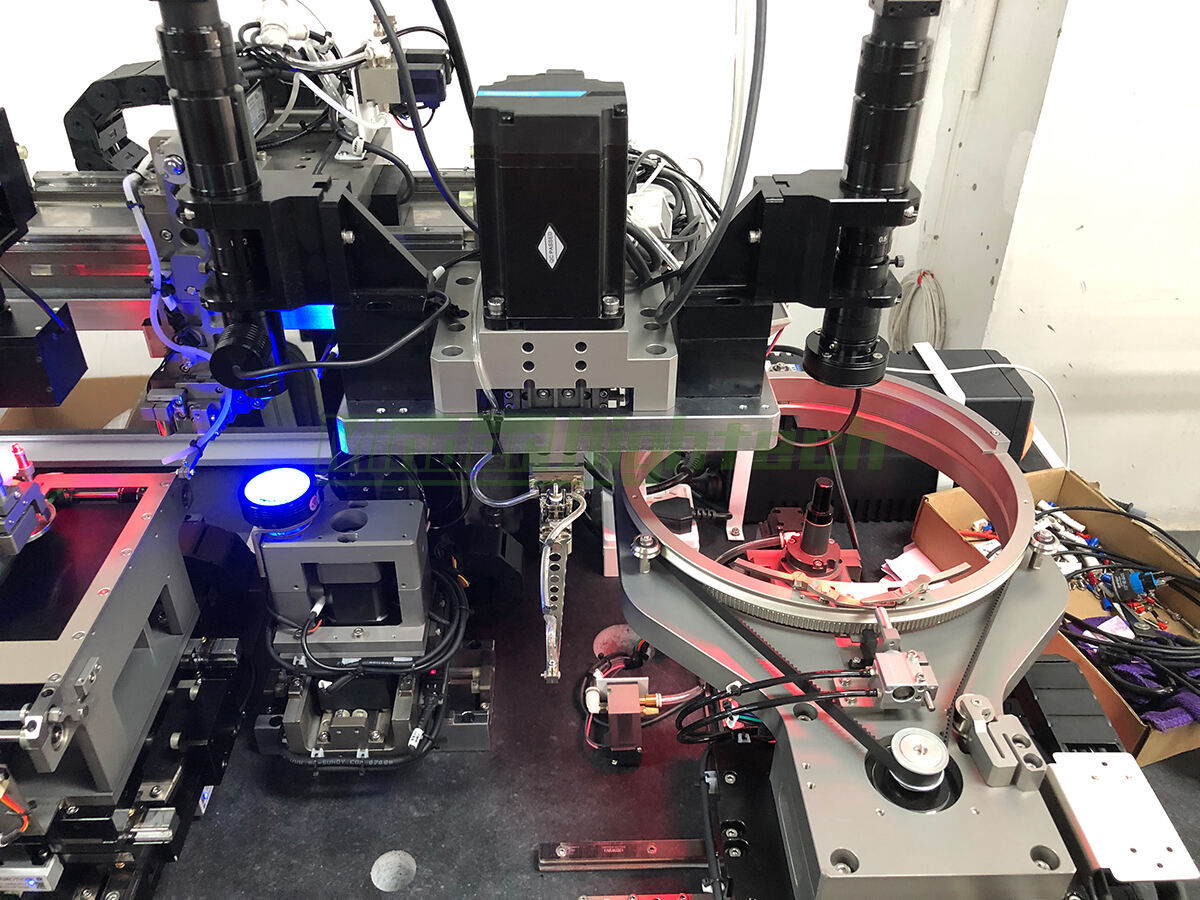

| Bonding arm | 90degree rotary |

| Motor | AC servomotor |

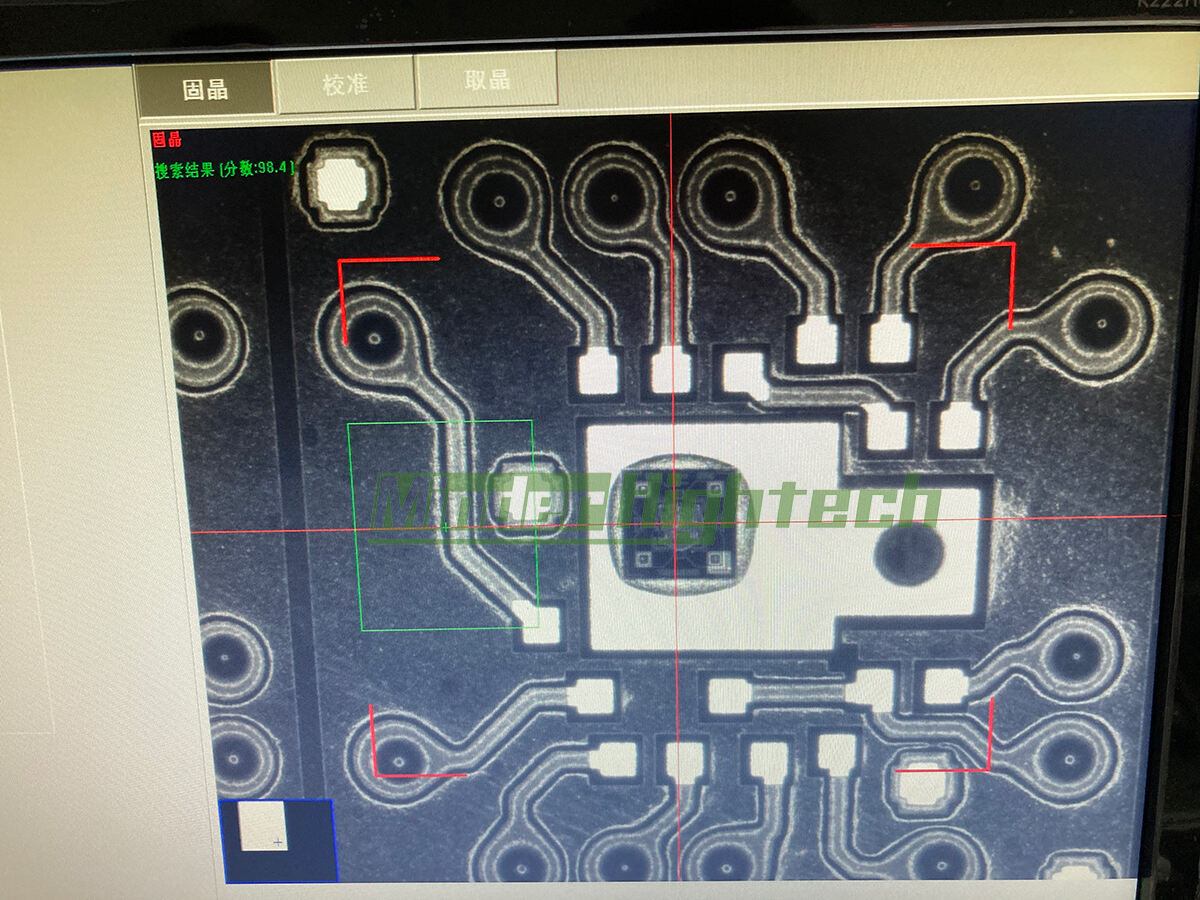

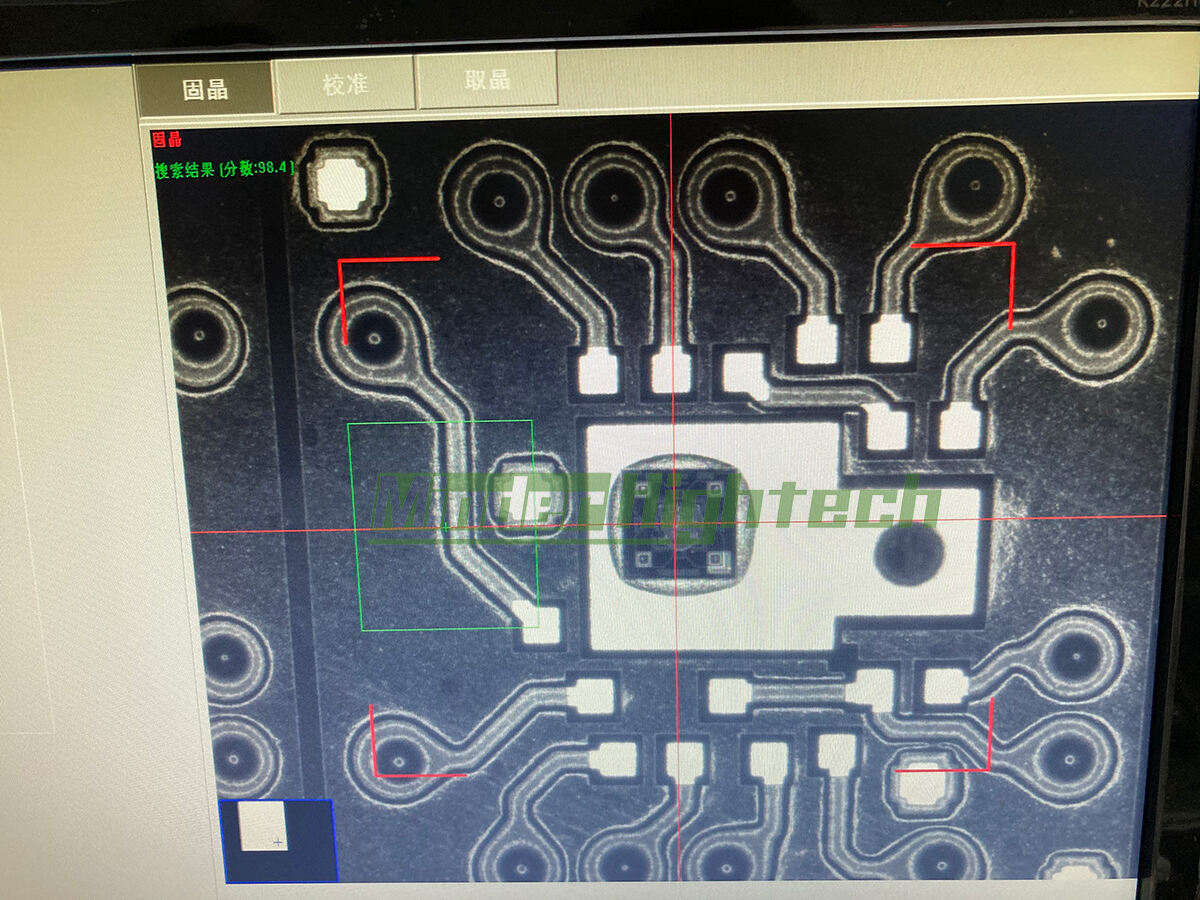

| Image recognition system | ||

| Method | 256 gray scale | |

| Check | ink dot,chipping die,crack die | |

| Display screen | 17inch LCD 1024*768 | |

| Accuracy | 1.56um-8.93um | |

| Optics magnification | 0.7X-4.5X |

| Bonding cycle | 120ms |

| Number of program | 100 |

| Max die number on one substrate | 1024 |

| Die lost check method | vacuum sensor test |

| Bonding cycle | 180ms |

| Glue dispensing | 1025-0.45mm |

| Die lost check method | vacuum sensor test |

| Input voltage | 220V |

| Air source | min.6BAR,70L/min |

| Vacuum source | 600mmHG |

| Power | 1.8kw |

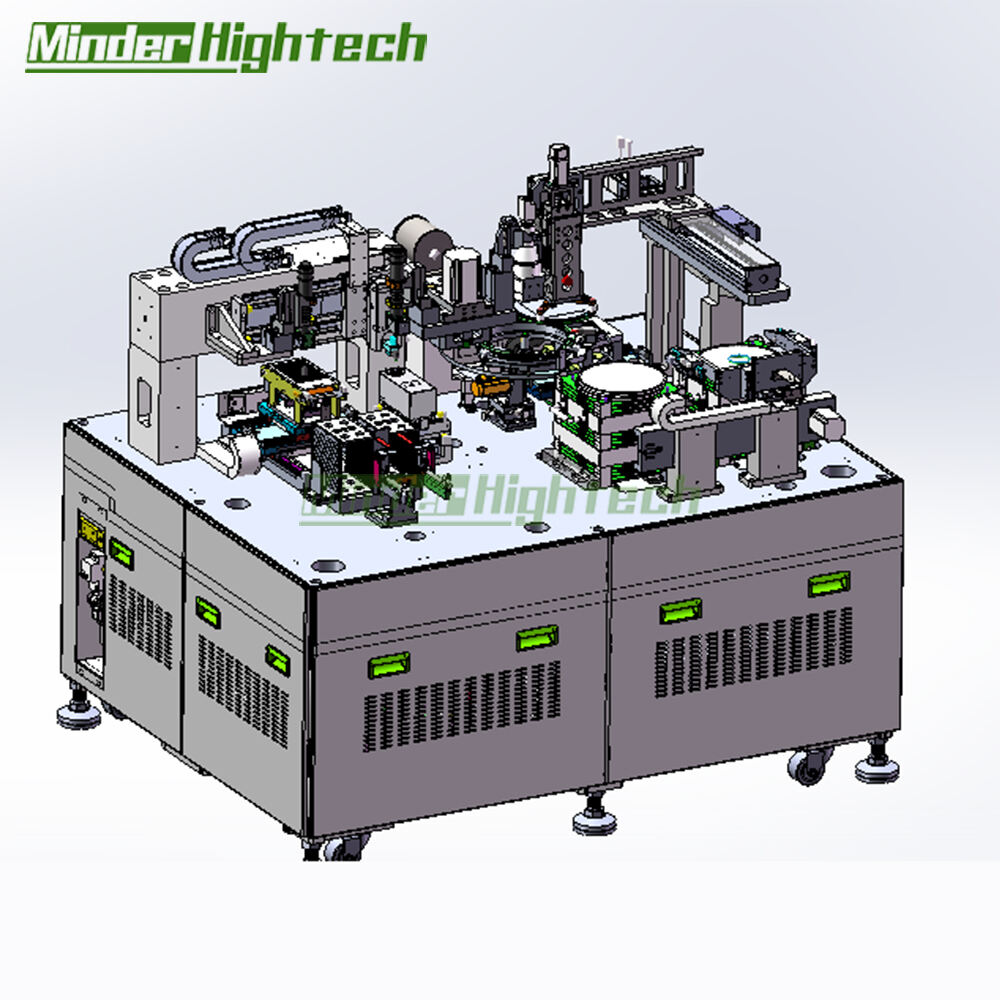

| Dimension | 1310*1265*1777mm |

| Weight | 680kg |

Our Factory

Our Factory

Packing & Delivery

Packing & Delivery

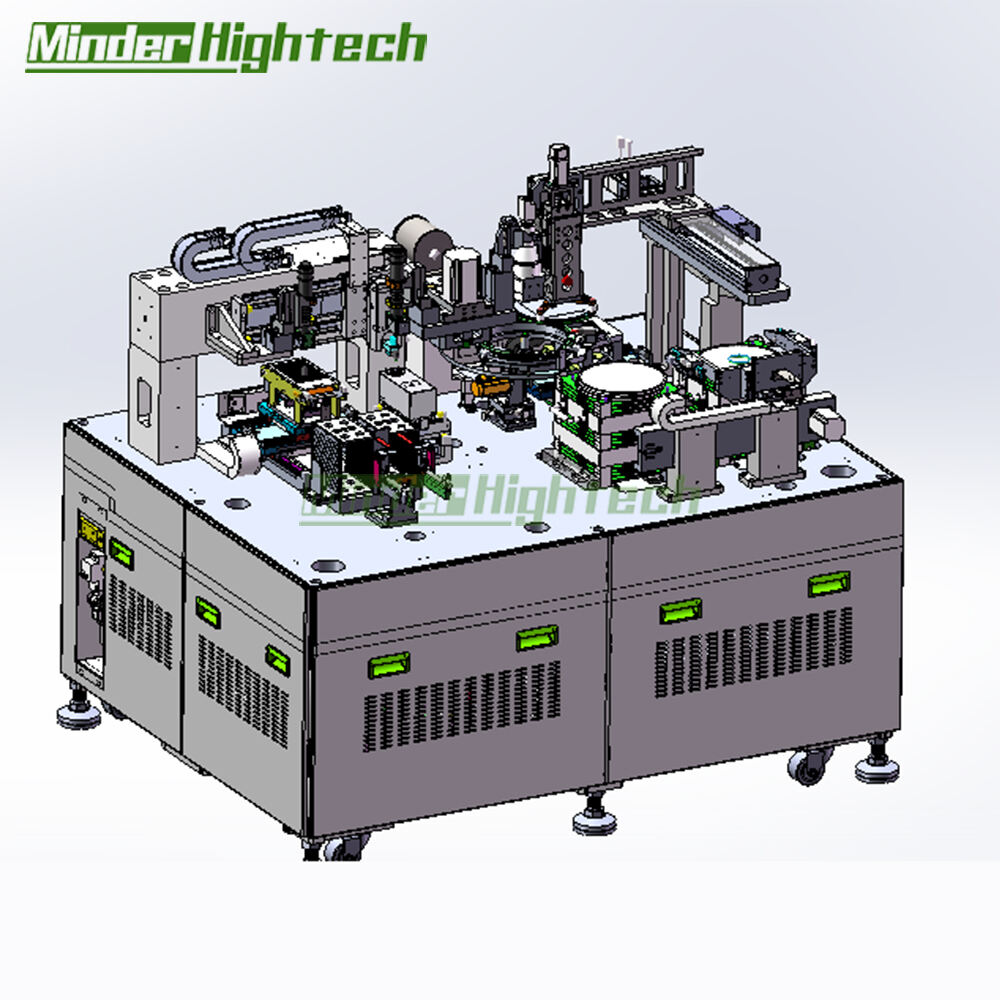

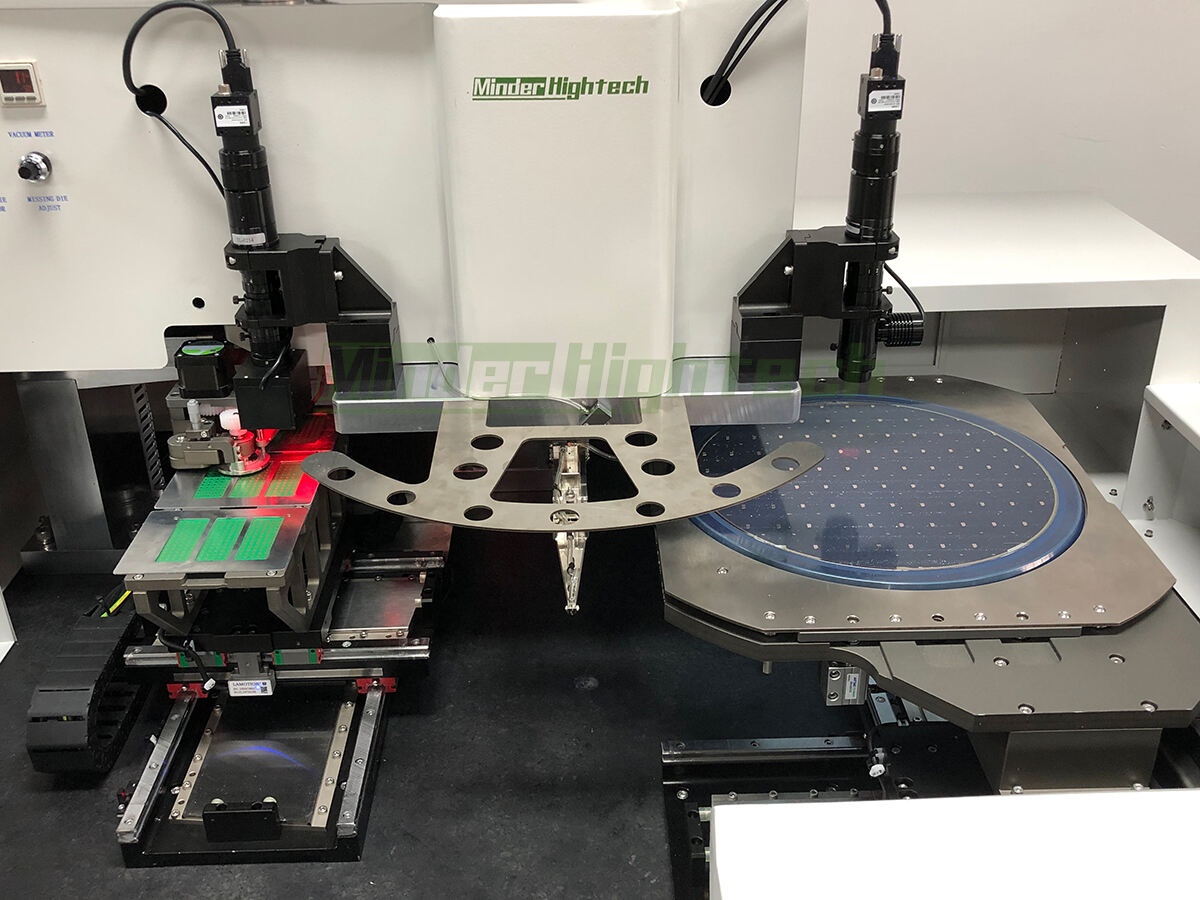

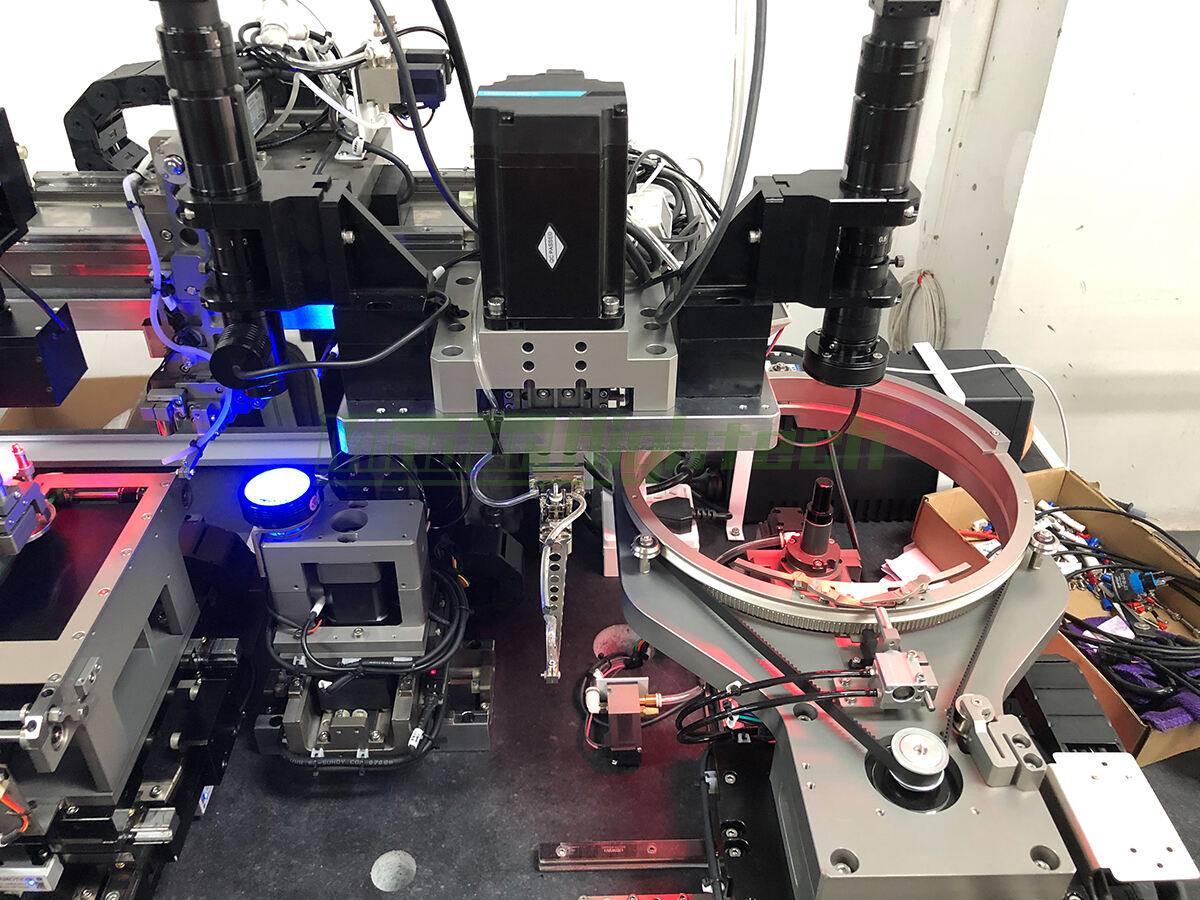

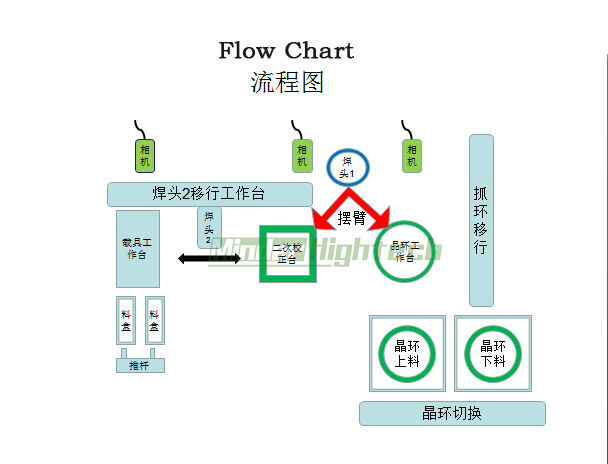

The Minder-Hightech Wafer Die Bonder is the perfect choice for any company in need of an efficient and reliable Die Attach bonding machine for in-line package manufacturing. This cutting-edge equipment is designed to deliver superior results with precision and accuracy, making it highly popular among industry professionals.

Made with durability and functionality in your mind, this consists of tough materials that guarantee exemplary performance and longevity. The device consists of advanced features which make it user-friendly, easy to run, and offer output is consistent.

With a give attention to innovation and quality, the Minder-Hightech brand has had the opportunity to produce this top-of-the-line bonding machine is equipped with the technology is latest to ensure every bond is completed efficiently. Good for any company excellence is seeking their Die Attach bonding process.

Among the biggest benefits of this is its accuracy is high and amounts. Its Jetting is advanced Technology that each relationship is made with extreme precision, which reduces mistakes and guarantees constant results.

The device also comes with a vision is advanced, rendering it very easy to spot any defects or anomalies. This allows you to take immediate corrective action, ensuring that your particular product is of the quality is highest possible.

Another feature is its versatility. It could be utilized with a variety is wide of sizes, ranging from because small as 5mm to as large as 100mm. This offers greater flexibility to allow for application is significantly diffent.

Designed for easy upkeep, with immediate access to machine elements that need repair or servicing is regular. This means that downtime is minimized, and the machine could be back operation as quickly as possible.

Get your hands on the Minder-Hightech Wafer Die Bonder today and experience the benefits of this top-quality machine.

Bonding workstage | ||

Load ability | 1 piece | |

XY stroke | 10inch*6inch(working range 6inch*2inch) | |

Accuracy | 0.2mil/5um | |

Dual work stage can feed continuously | ||

Wafer workstage | ||

XY travel stroke | 6inch*6inch | |

Accuracy | 0.2mil/5um | |

Wafer position accuracy | +-1.5mil | |

Angle accuracy | +-3 degree | |

Die dimension | 5mil*5mil-100mil*100mil |

Wafer dimension | 6inch |

Picking up range | 4.5inch |

Bonding force | 25g-35g |

Multi wafer ring design | 4 wafer ring |

Die type | R/G/B 3type |

Bonding arm | 90degree rotary |

Motor | AC servomotor |

Image recognition system | ||

Method | 256 gray scale | |

Check | ink dot,chipping die,crack die | |

Display screen | 17inch LCD 1024*768 | |

Accuracy | 1.56um-8.93um | |

Optics magnification | 0.7X-4.5X | |

Bonding cycle | 120ms |

Number of program | 100 |

Max die number on one substrate | 1024 |

Die lost check method | vacuum sensor test |

Bonding cycle | 180ms |

Glue dispensing | 1025-0.45mm |

Die lost check method | vacuum sensor test |

Input voltage | 220V |

Air source | min.6BAR,70L/min |

Vacuum source | 600mmHG |

Power | 1.8kw |

Dimension | 1310*1265*1777mm |

Weight | 680kg |

The Minder-High-tech Wafer Die Bonder is the perfect choice for any company in need of an efficient and reliable Die Attach bonding machine for in-line package manufacturing. This cutting-edge equipment is designed to deliver superior results with precision and accuracy, making it highly popular among industry professionals.

Made with durability and functionality in your mind, this consists of tough materials that guarantee exemplary performance and longevity. The device consists of advanced features which make it user-friendly, easy to run, and offer output is consistent.

With a give attention to innovation and quality, the Minder-High-tech brand has had the opportunity to produce this top-of-the-line bonding machine is equipped with the technology is latest to ensure every bond is completed efficiently. Good for any company excellence is seeking their Die Attach bonding process.

Among the biggest benefits of this is its accuracy is high and amounts. Its Jetting is advanced Technology that each relationship is made with extreme precision, which reduces mistakes and guarantees constant results.

The device also comes with a vision is advanced, rendering it very easy to spot any defects or anomalies. This allows you to take immediate corrective action, ensuring that your particular product is of the quality is highest possible.

Another feature is its versatility. It could be utilized with a variety is wide of sizes, ranging from because small as 5mm to as large as 100mm. This offers greater flexibility to allow for application is significantly different.

Designed for easy upkeep, with immediate access to machine elements that need repair or servicing is regular. This means that downtime is minimized, and the machine could be back operation as quickly as possible.

Get your hands on the Minder-High-tech Wafer Die Bonder today and experience the benefits of this top-quality machine.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved