Ste se kdaj spraševali, kako se izdelajo ti slabi dizajni metalnih delov? Te dizajne lahko ustvarite na primer skozi postopek graviranja. Prvi od teh je graviranje, ki vključuje odstranjanje nekaterih količin metala s površine, da se ustvari želeni dizajn ali vzorec. V zgodnjih dneh so bili ti postopki ročno operirani, kar pomeni, da je oseba morala pazljivo drsnikom odstraniti dele metala, da bi razširila slike ali črke. Vendar pa danes obstajajo lepe stroje, ki to lahko storijo samodejno in znatno hitreje. En tak stroj je samodejni gravirni stroj.

V časih, ko še ni bilo izumljenih samodejnih očinkovalnih strojev, so delavci morali ustvarjati načrte ročno. Z uporabo posebnih orodij so drsali kovino in tako ustvarjali svoje vizije v obliki načrtov. To ni bila le težka fizična dela, ampak je tudi zelo dolgo trajalo. Si predstavljate, da bi se urami drsali za eden vzorec?! Samodejni očinkovalni stroj pa je spremenil vse. Vse delo zdaj lahko opravi stroj. Pripelje s programom, ki mu pove, kjer očinkovati, in sam dokonča vse ostalo. To prihrani veliko dragocenega časa in poenostavi celoten proces očinkovanja površine za delavce.

Ena največjih prednosti morda je, da lahko avtomatska risalnica obdeluje različne dele hkrati. Ta zmogljivost je zlasti uporabna za uporabnike, ki delajo v potrebi po visoko količinski proizvodnji. Namesto da bi delali po enem kosu naenkrat, se lahko stroj ukvarja s več kosov hkrati. To pomeni, da lahko podjetja zaključijo svoje naročila močno hitreje kot čisto ročno. Zato v dolgotrajnem shranjujejo stroške in čas podjetij, kar je zelo pomembno za vsako podjetje, da si ohrani svoje mesto. Tako jim ta stroj pomaga, da dosežejo svoje proizvodne cilje veliko učinkoviteje.

Velika prednost samodejne ožigalne mašine pri prodaji je, da lahko izdelujemo zelo podrobne in kampanjske rezove bolje. Mašina je računalniško programsko nadzorovana, zato lahko izvaja zelo točne in merljive reze katerega koli oblika. Natančnost je tako visoka, da je mogoče izvršiti tudi najmanjše aspekte načrta brez napak. To je ključni faktor za podjetja, ki iščejo izdelavo močnih, zapletenih delov. Podjetja lahko uporabijo to samodejno ožigalno mašino, da zagotovijo ravno to, saj potrošniki pogosto iščejo izdelke, ki so bolj privlačni.

Je tudi izredno varno, ko gre za avtomatsko očrpalno strojno opremo. Ker stroj opravlja vse delo, zelo zmanjša tveganje za kogarkoli operatorja, ki je v tem času odgovoren. Ta stroj prav tako veliko pomeni pri zagotavljanju varnosti delavcev. Poleg tega ima naprava poseben nadzorni sistem, ki podpira točno očrpavanje vsakič. To naredi rezultate izredno zanesljive in konzistentne. Pri ročnem očrpanju obstaja možnost človeške napake, v avtomatiziranem stroju pa je to tveganje zmanjšano na minimalen ravni. To je ključno za podjetja, ki določijo visoke standardne merilne vrednosti za svoje produkte.

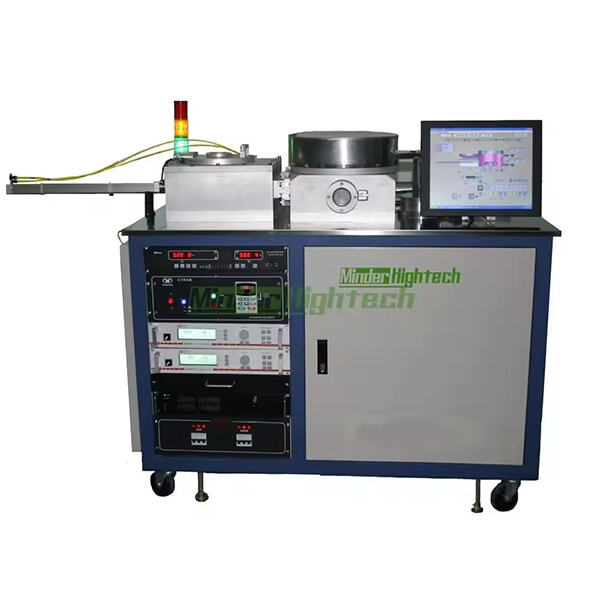

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved