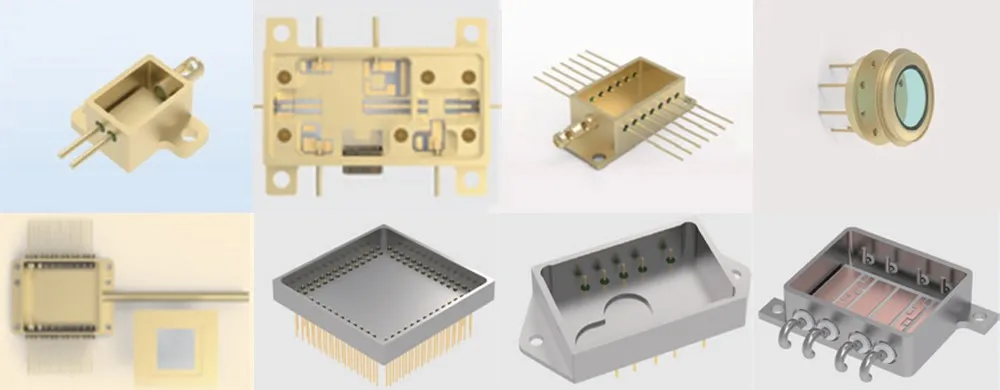

La serie MDNY-YAYD160 de nuestro equipo de presión de hélice/flúor, combinada con un detector de fugas de espectrómetro de masa de helio y un detector de fugas de calentamiento de aceite pesado de flúor, es un equipo automatizado de presión de helio/flúor diseñado para la inspección fina y gruesa de componentes electrónicos como circuitos integrados, dispositivos semiconductores y productos electrónicos.

El aceite de flúor/gas de helio tiene excelentes propiedades dieléctricas, inercia química, aislamiento eléctrico y resistencia a altas y bajas

resistencia a la temperatura. No es corrosivo para los componentes electrónicos y no afecta sus diversos parámetros. Lo que lo convierte en un medio ideal de detección de fugas para pruebas de hermeticidad de componentes electrónicos.

El principio de inspección fina por presurización con helio: Primero, coloque el dispositivo original en un contenedor sellado que pueda ser

presurizado, y presurice el componente con helio durante un período de tiempo determinado. Si existe una fuga en el componente, el gas de helio será forzado hacia la cavidad interna. Luego retire el componente probado y colóquelo en la caja de detección del detector de fugas de espectrómetro de masa de helio para realizar una prueba de vacío. Si hay una fuga en el componente, el gas de helio que ingresó a su cavidad interna se desbordará hacia el detector de fugas, y este mostrará la tasa de fuga.

El principio del método de detección de fugas con aceite de flúor es que las moléculas del medio de detección son pequeñas, por lo que incluso fugas pequeñas pueden pasar. Si hay fugas en el dispositivo, durante la presurización, el aceite de flúor ligero/helio entrará en el dispositivo bajo presión. Debido a que la temperatura de punto de ebullición del aceite de flúor ligero es aproximadamente de 45,7 ℃, al colocarlo en aceite de flúor pesado a una temperatura de 125 ℃, el aceite de flúor ligero se vaporiza rápidamente, causando un aumento rápido de la presión dentro de la cavidad del componente. El gas dentro de la cavidad saldrá por la fuga, lo que provocará la aparición de burbujas en el aceite de flúor de alta ebullición.

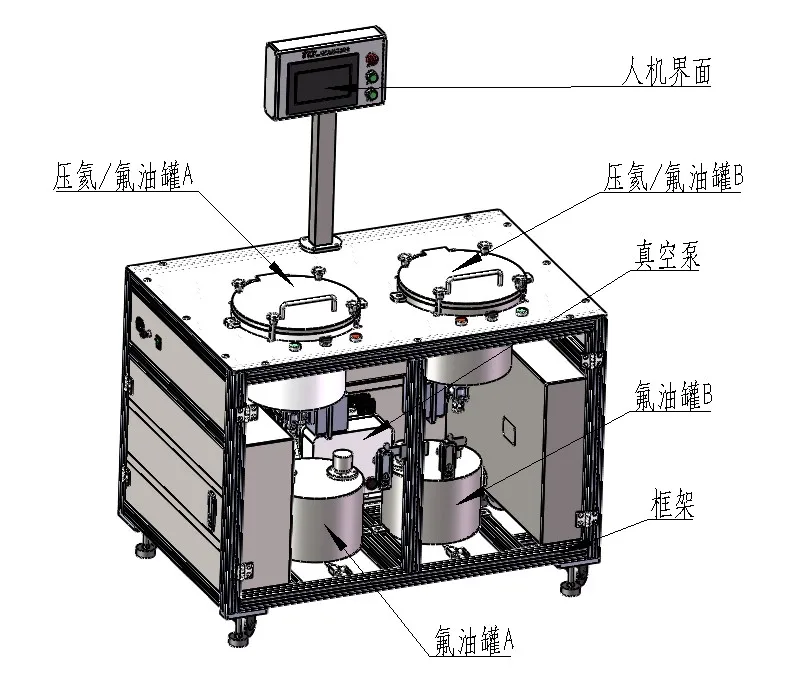

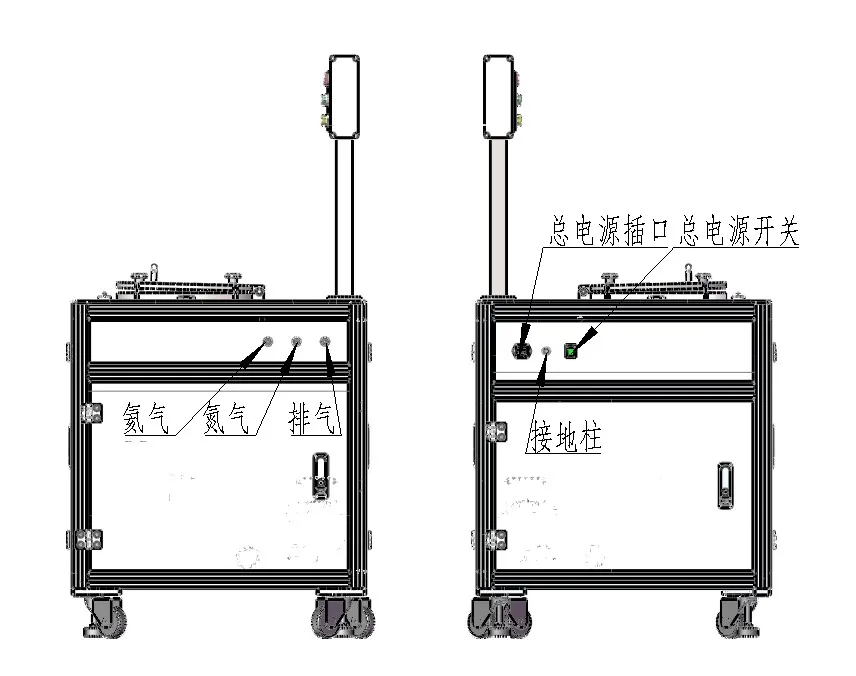

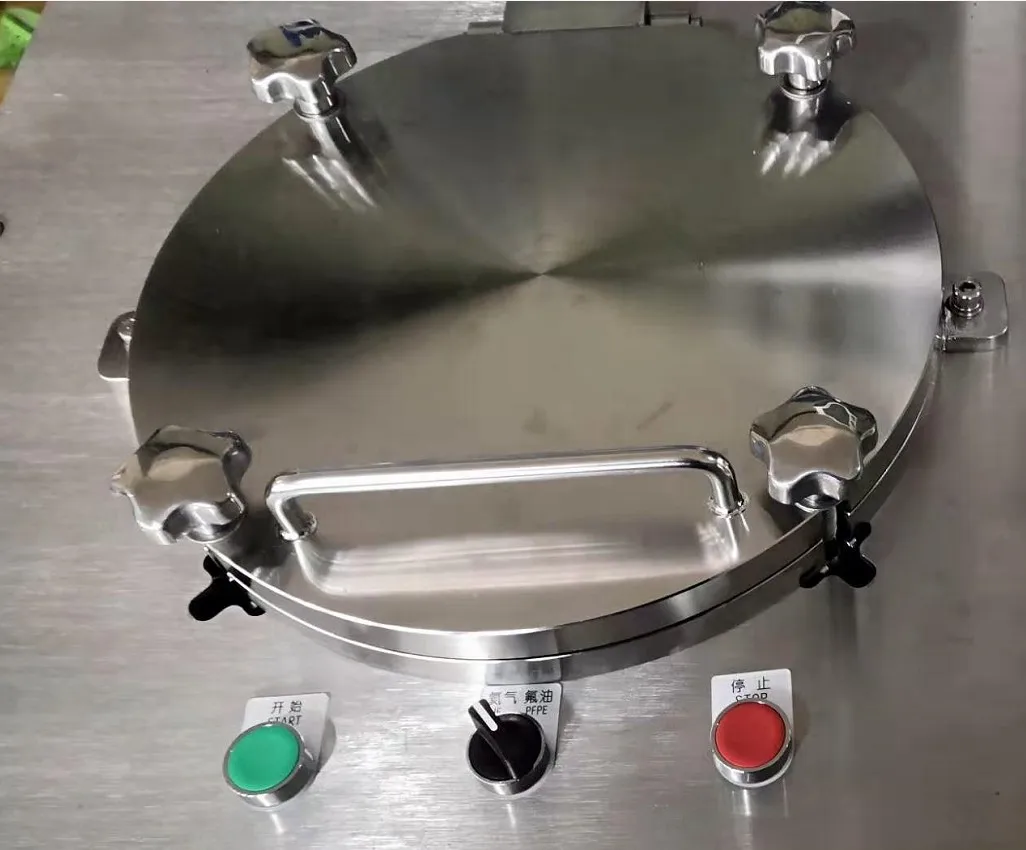

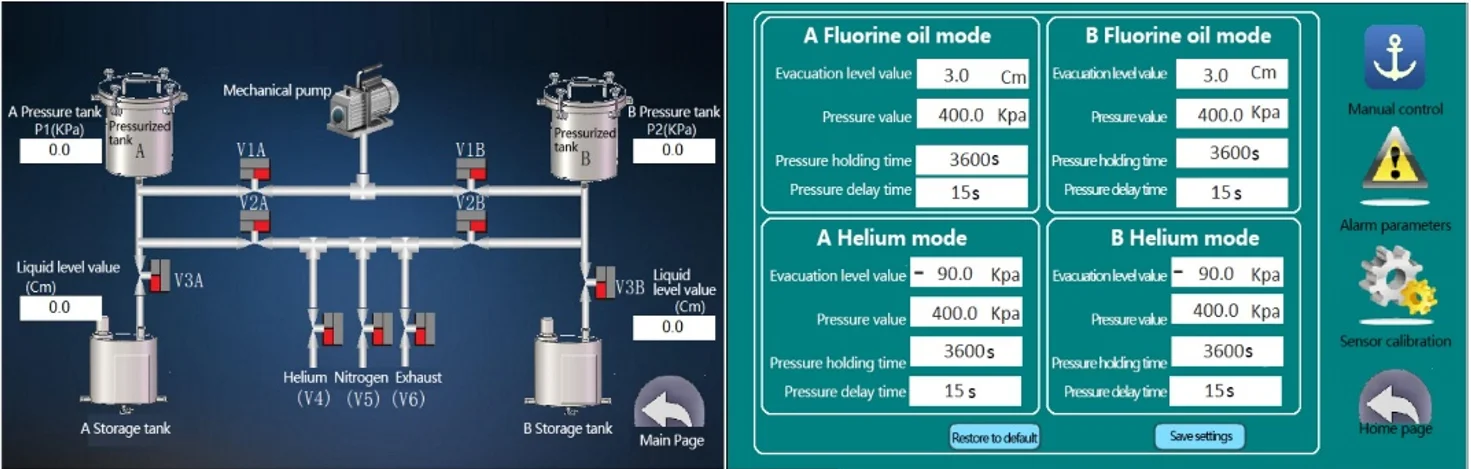

Todas las válvulas de este equipo están controladas por válvulas de bola eléctricas, que pueden operarse con un solo clic mediante un sistema de control basado en PLC. Además, está equipado con una pantalla táctil, lo que permite observar constantemente la presión y el nivel del líquido dentro del tanque de aceite de flúor/helio presurizado.

Este dispositivo tiene una estructura compacta, es fácil de mover, es fácil de operar, tiene alta eficiencia de detección y es seguro y confiable a largo plazo. La apariencia del equipo se muestra en el diagrama: