Wire bonding is a technique used to join different elements in electronic devices. Having this relationship is essential in keeping all the pieces functioning together harmoniously and effectively. Ultrasonic wire bonding has been the talk of late when it comes to one special type of wire bonding. This is being widely used these days since it has got many advantages compared to the previous approaches.

Ultrasonic wire bonding is a new inventive method used to join the wires. People previously combined wires using either heat or pressure. While it ran great, this was far from ideal. Instead, ultrasonic wire bonding uses high-frequency vibrations. These are very fast vibrations and they cause the wires to stick together better. This has necessitated the use of ultrasonic bonding which provides stronger More reliable connections than those made with previous methods.

There are a few reasons why ultrasonic bonding is hyperspace faster than traditional wirebonding techniques. It does it a lot faster for one main reason. Because of the "speed" in this process, which happens when using ultrasonic bonding instead, a frame can be made quickly. This rapid production makes it easier for manufacturers to create more electronic devices over a shorter amount of time.

Stronger, and more precise - probably the two most important advantages of ultrasonic bonding. This is thanks to the high-frequency vibrations that are employed during this process, creating a strong connection between the wires. The bonding is so secure that the wires are well connected and less likely to break or come off. This is tremendously important in the connection devices, where shorting can cause devastating and unreliable operations.

Ultrasonic technology never only limited in wire bonding any many other fields using it. For instance, it can be used for cleaning objects as well as cutting materials and parts together via welding. Ultrasonic technology is vital in the case of wire bond, for making superstrong bonds that are especially required to get electronic devices running. Using this highly advanced technology, manufacturers can guarantee longevity in their products.

Ultrasound wire bonding has transformed the way electronics are produced in reality. This made the process significantly faster and efficient, resulting in much better wire connections. Ultimately allowing for devices to be made faster and at a much lesser cost. This is great news for consumers of electronic products as it can help create superior quality and affordable e-product options.

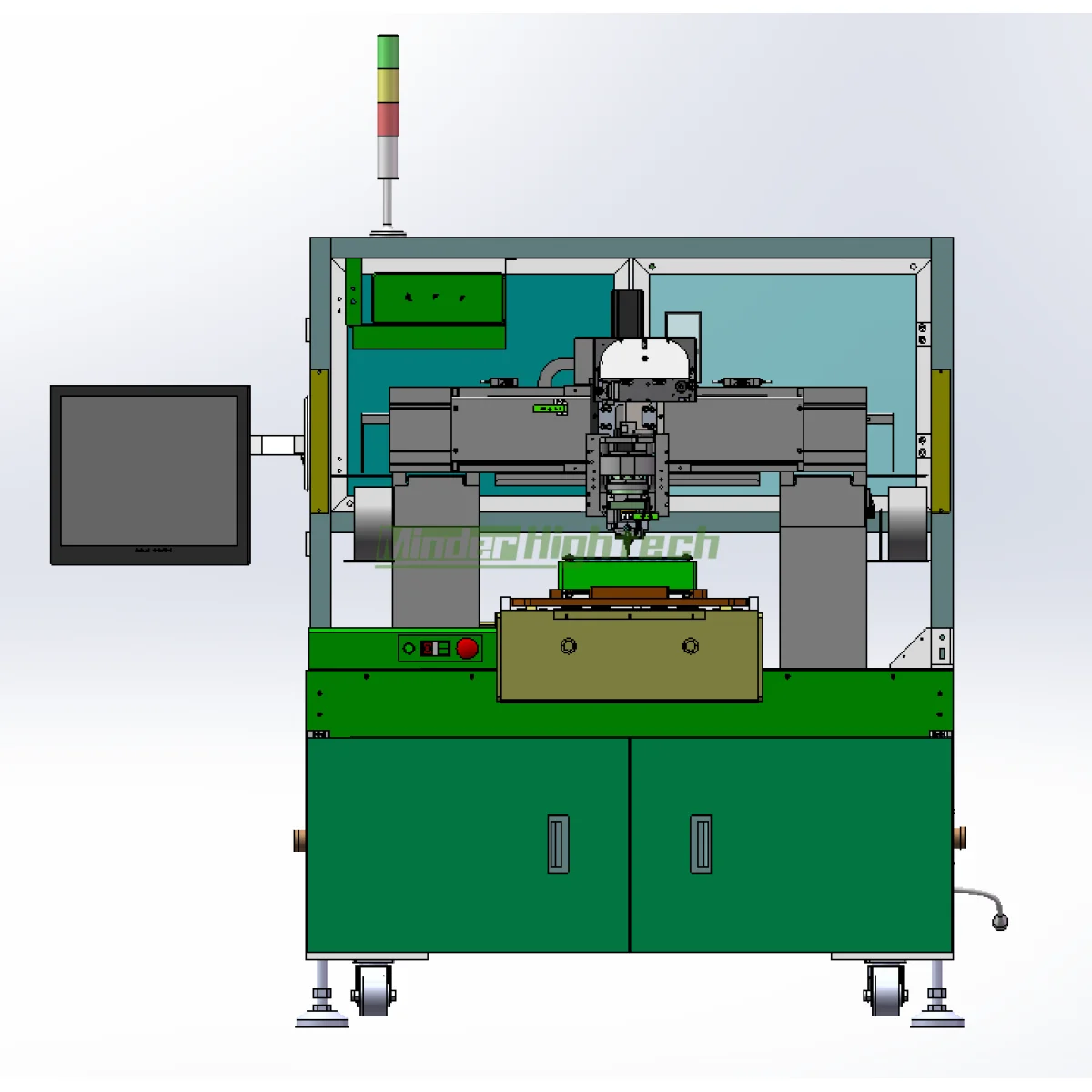

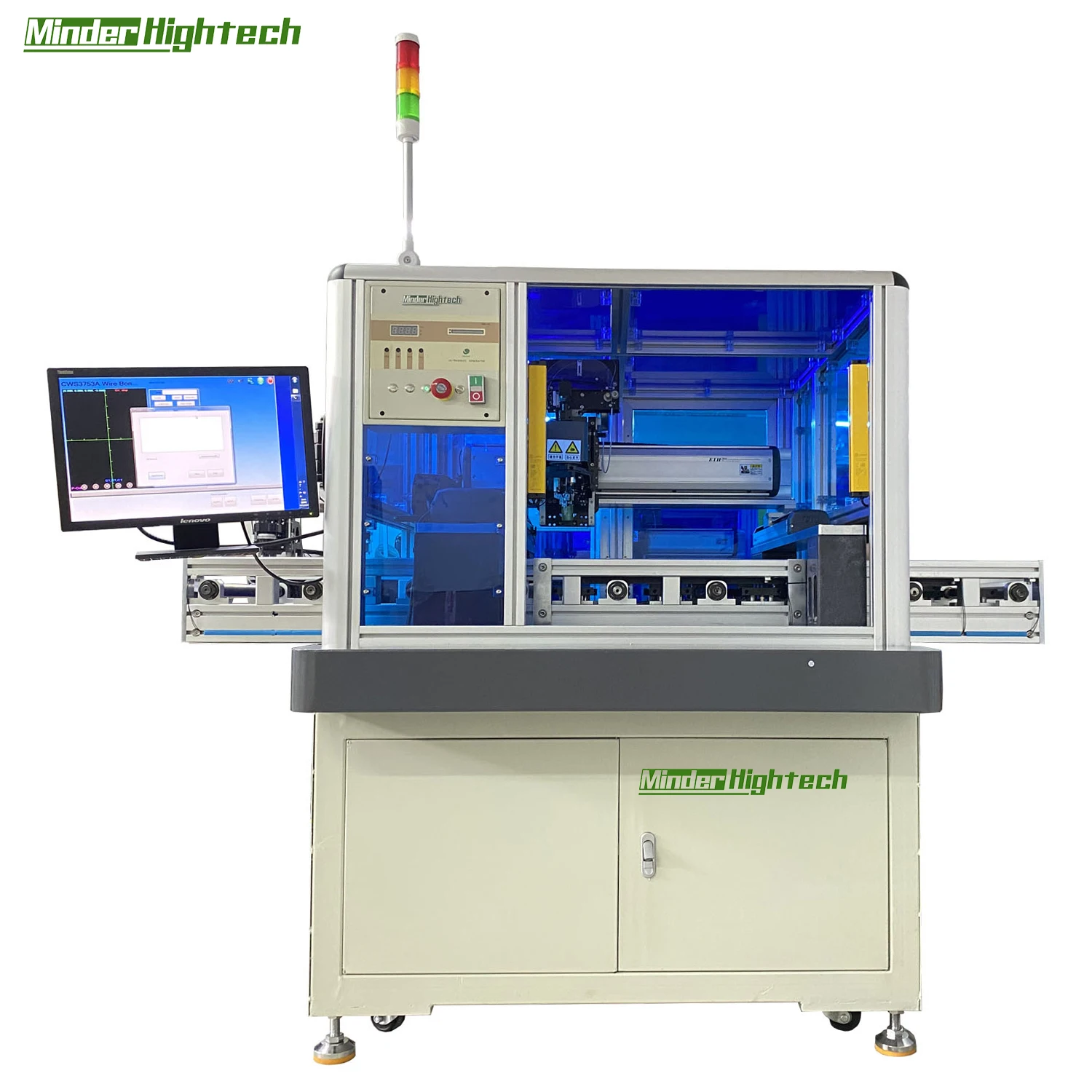

Minder-Hightech is now a very Ultrasonic Wire Bonding brand in the industrial world, based on many years of experience in machine solutions and good relationship with oversea customers of Minder-Hightech, we created "Minder-Pack" which focuses on the machinery on packages solution as well as other high-value machines.

We have a Ultrasonic Wire Bonding range of products, including: Wire bonder and die bonder.

Minder-Hightech is sales and service Ultrasonic Wire Bonding of electronic and semiconductor product industry equipment. We have over 16 years of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Minder Hightech comprises a team of highly educated engineers, professionals, and staffs with outstanding expertise and experience. Our brand's products have spread to major industrialized countries across the globe aiding customers to improve efficiency, Ultrasonic Wire Bonding and increase the quality of their products.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved