In the vast and exciting land of electronics, getting tiny wires connected to any given device is key. They do this through a process called wire bonding. It is extracted to make the electronic components that are used in our daily lives like laptops, mobiles and tablets. These devices would be of little use if the wire bonding is not there.

However, due to the fact that the wires are so thin (smaller than a mm!) wire bonding is very critical. For reference, this is about the size of a human hair. If the wires are not connected properly, your equipment will simply fail to operate and you would be rightfully annoyed. Wire bonding is a skill that requires practice and patience. Folks that do this have to be laser-focussed and with hands of stone, rocks solid and steady... everything must perfectly fall into its right place.

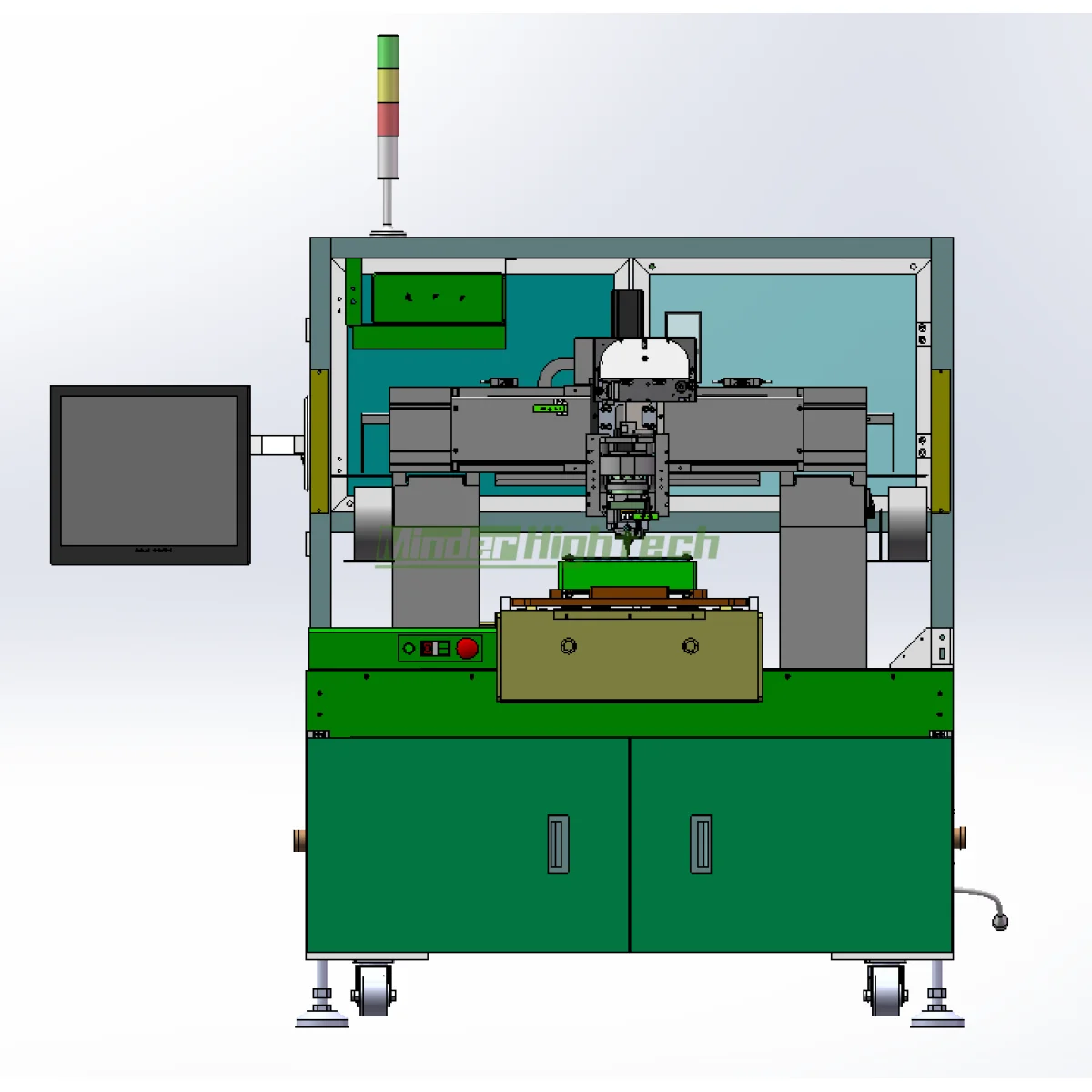

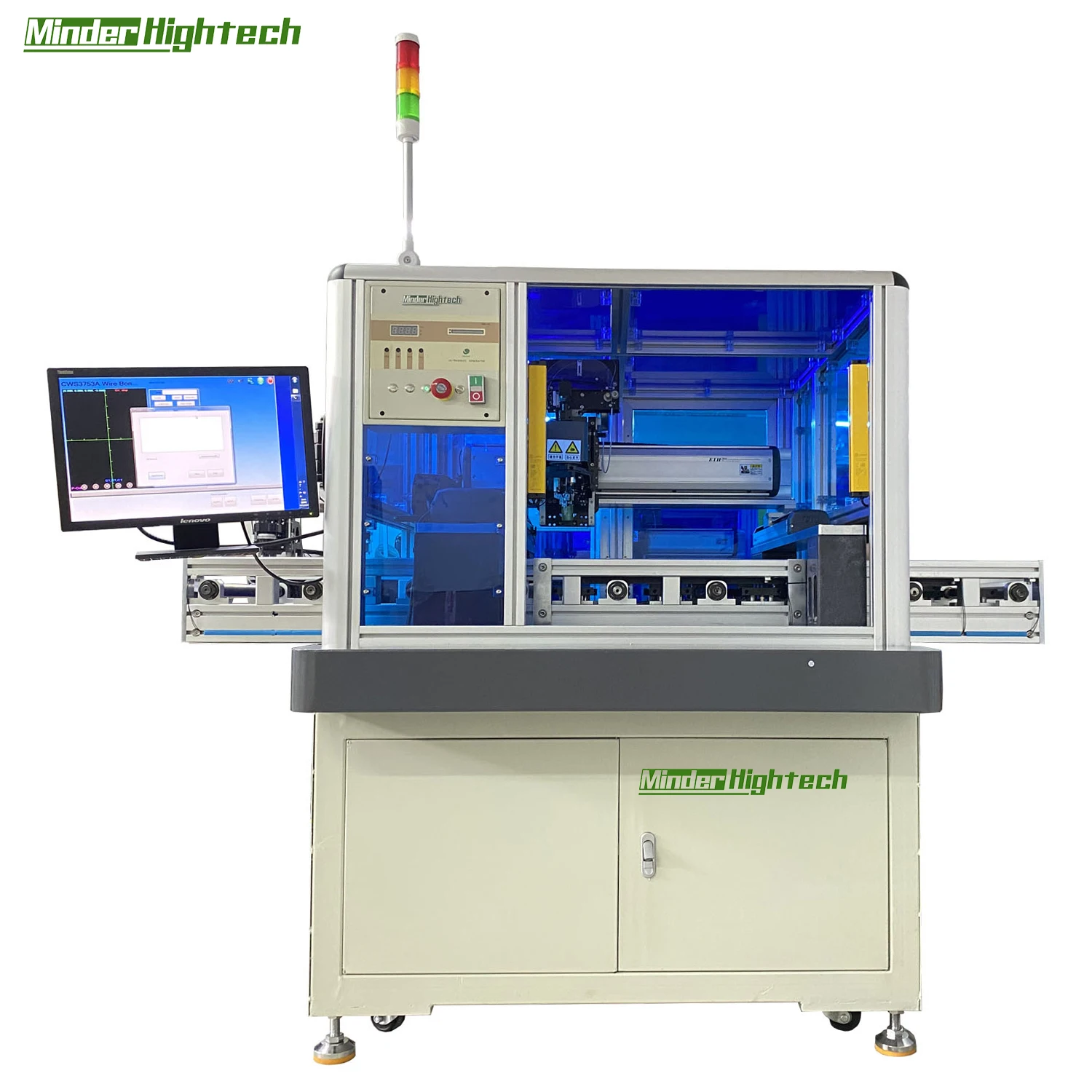

Wire bonders are the specific equipment utilized for wire bonding. The first type is simple which require a person to operate, moving on there are some types of machines that have an ability to work all alone and do not need any help. The main reason is that the automatic machines work faster and do not need to halt anywhere therefore most of electronic makers try using them rather than manually guided ones.

Those are use automatic wire bonders make thousands a day. They can bond wires nonstop which implies they do not take breaks like a human. These machines can then move very small wires really fast and with great accuracy, which makes them work quickly and make many electronic devices in a shorter time. This efficiency has played an important role in our fast world today where we require gadgets for many reasons daily.

The machines used in microelectronics assembly must cater to wires that are smaller than a human hair! This seems like an impossible task, considering that the connections need to be extremely robust and dependable. One small error and you might brick the whole expensive electronic device that's why everyone involved in this work has to be super cautious.

Two popular bonding methods are wedge Bonding and ball bond. Wedge bonding uses a wedge-shaped tool to push the wire in place for making the connection. Ball bonding is where we heat the wire until its soft and then forms a little ball at one end of the OCR. After this a ball is pressed upon the electronic part to make sure they are secured with each other. In summary, both are effective in practice but choice should be determined by the needs of the device being manufactured.

Considering the sister method as a backbone of high-tech electronics because it is less failure-prone. A wire bond is robust - it can withstand the heat, vibrations and other hazards that are standard fare in high-tech devices. That means the devices can still operate as intended even when they are used in tough environments.

Minder-Hightech is a sales and service representative for electronic and semiconductor products industry equipment. We have over Wire bonder of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Minder-Hightech Wire bonder become a well-known brand in industrial world, based on the years of machine solution experience and good relationship with oversea customers from Minder-Hightech. We created "Minder-Pack" which focuses on the manufacturing of packages solution, as well as other high value machines.

Our primary products are: Die bonder, Wire bonder, Wafer grinding Dicing saw Wire bonder, Photoresist removal machine, Rapid Thermal Processing, RIE, PVD, CVD, ICP, EBEAM, Parallel sealing welder, Terminal insertion machine, Caparitar winding device, Bonding tester, etc.

Minder Hightech is comprised by a team of highly educated experts, highly skilled Wire bonder and staffs, with outstanding professional expertise and experience. Our products are accessible in the major industrialized countries all over the world, helping our clients to increase their efficiency, lower their cost and enhance the quality of their products.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved