Microchips are tiny electronic parts that go into a lot of things we — and machines — use often. They can be found in both phones and computers, as well as the cars we drive and even our kitchen appliances! While these chips are tiny, they serve a crucial function by enabling our devices to work correctly. Have you ever pondered upon how these mini chips are built and packaged? For packaging they use special machines, the name of which I will not specify for a reason

It packages the microchip securely in mobile device compatible case and then wire it up. These machines work diligently to make sure each chip is safe. In the absence of these machines, fine chips get easy broken or damaged with ease! This is why businesses utilize the smart packaging solutions for protecting their microchips. They ensure the safety of chips during transport and storage.

The electronics world is continuously innovating, and so are the machines packaging chips. New inventions and with new technology guys are finding ways to improve them, make it work faster & unique is Nowadays trend. As a result, they can work faster and produce better quality outputs that are more consistent.

3D Printing: A Cool new feature in the domain of Packaging machines, This technology is a boon for companies who can create their own parts as per the requirements of machines in no time. Custom fit in the case of 3D printing can save you time and money by producing parts that perfectly integrate. In addition, it has the benefit of making machines lighter and less expensive to fabricate, which is good for companies who are looking to cut costs while continuing to produce top-of-the-line pieces.

High-performing equipment also ensures packaging accuracy. They will work 24 hours a day never get tired and the process does not have to slow down or make logical mistakes like humans This allows for faster, higher-quality products to be made. This is very necessary to make sure the chips are packaged properly, and they have less scope of error which can help in reducing errors when machines do that work.

Laser Marking is one type of smart technology used in chip packaging. Chip cases and their exact labels are created with the help of a process called laser marking. Use these labels to track your products and avoid mistakes. Want to ensure each chip goes in the right place, labels help with identifying what is what.

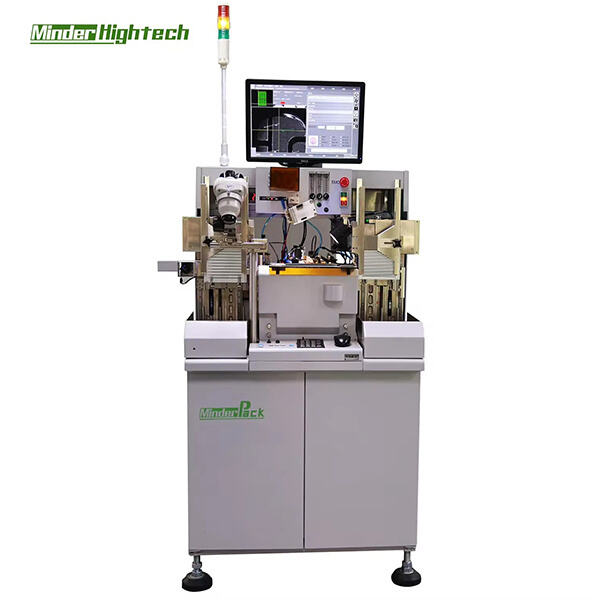

A pick-and-place machine is one example of such a robot. For speeding up the process of placing microchips on circuit boards fast and with more precision than a human. Good for mass production of chips in a jiffy The pick-and-place machines also help companies decrease human work, which in return saves time and money for organizations. This makes it possible for enterprises to meet the large demand of microchips, without reducing quality.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved