Why is it necessary to remove photoresist?

As is well known, photoresist is the core material for semiconductor wafer manufacturing. In the process of wafer manufacturing, photolithography accounts for about 35% of the total wafer manufacturing cost and consumes 40-50% of the entire wafer process, making it the most critical process in semiconductor manufacturing.

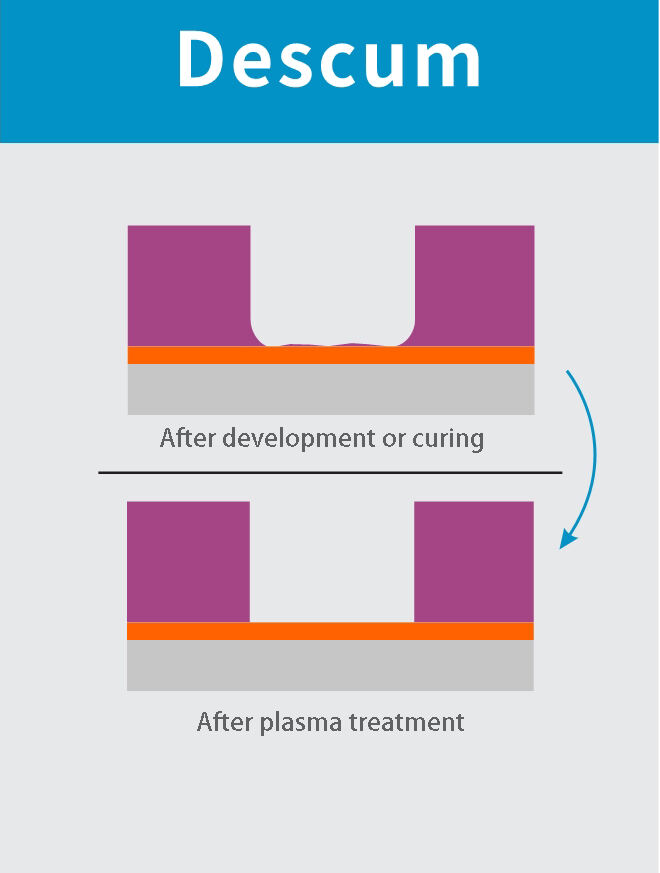

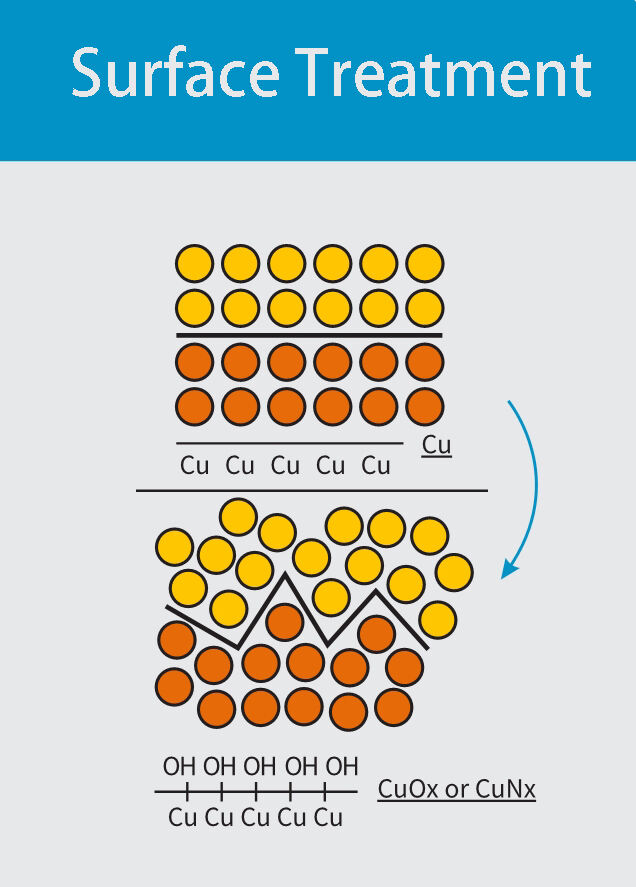

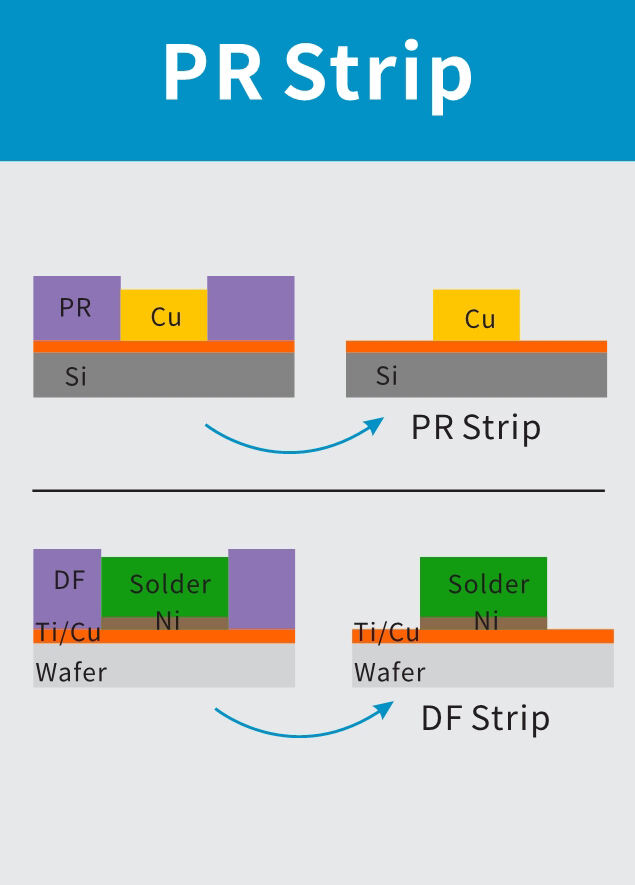

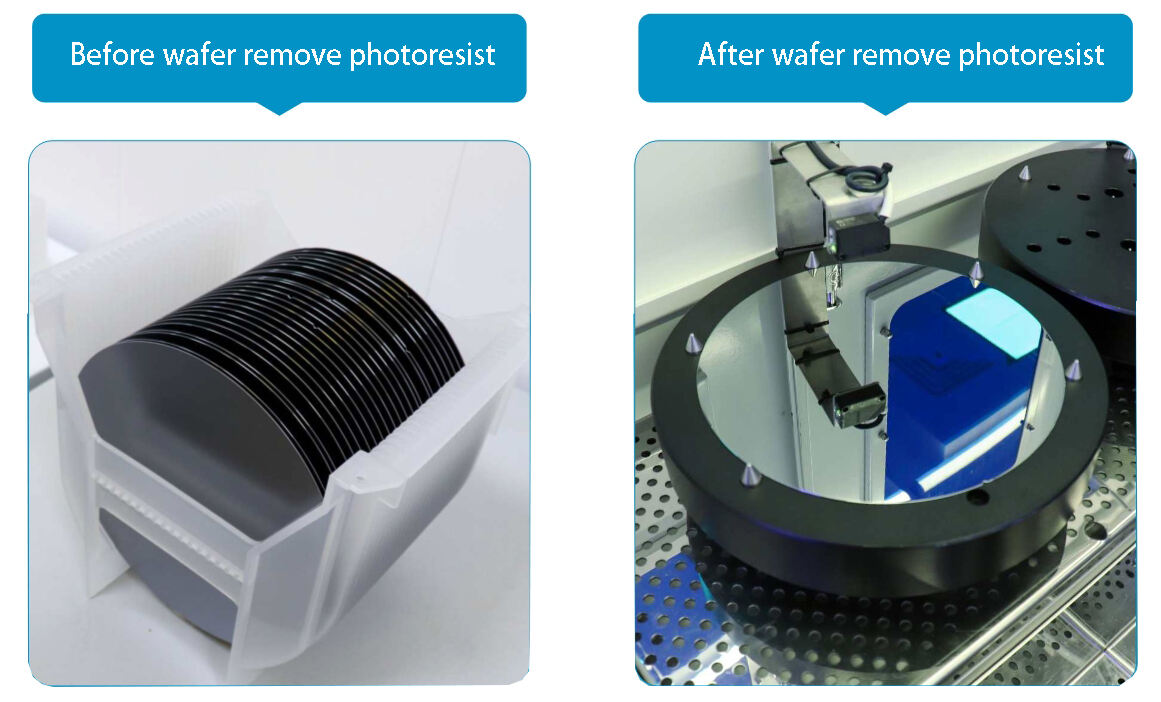

An indispensable step in the photolithography process is the removal of photoresist from the wafer. After completing the process of pattern replication and transfer, the remaining photoresist on the wafer surface needs to be completely removed.

ICP plasma removal of photoresist

The ICP plasma photoresist removal machine adopts a high-density, low damage plasma source design and is equipped with mature remote ICP technology to achieve a high level of photoresist removal rate and damage suppression; Adopting an independent chamber structure design to achieve uniform flow field distribution and excellent uniformity in removing photoresist.

Product advantages:

● Compatible with mainstream 4-8-inch circular wafers

● Can process two wafers at a time, maintaining a lower temperature during the processing

● High degree of automation, achieving fully automatic wafer loading and unloading, cleaning process

● High plasma density, good removal effect of photoresist

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved