Etching:

Two electrodes are available for etching processes:

■ Electrode with wide temperature range (-150°C to +400°C), cooled by liquid nitrogen, liquid circulating refrigerant or variable temperature resistor. Optional purge and liquid exchange unit to automatically switch process mode.

■ Liquid controlled electrode supplied by circulating cooling unit.

Deposition:

Two electrodes are available for deposition process selection:

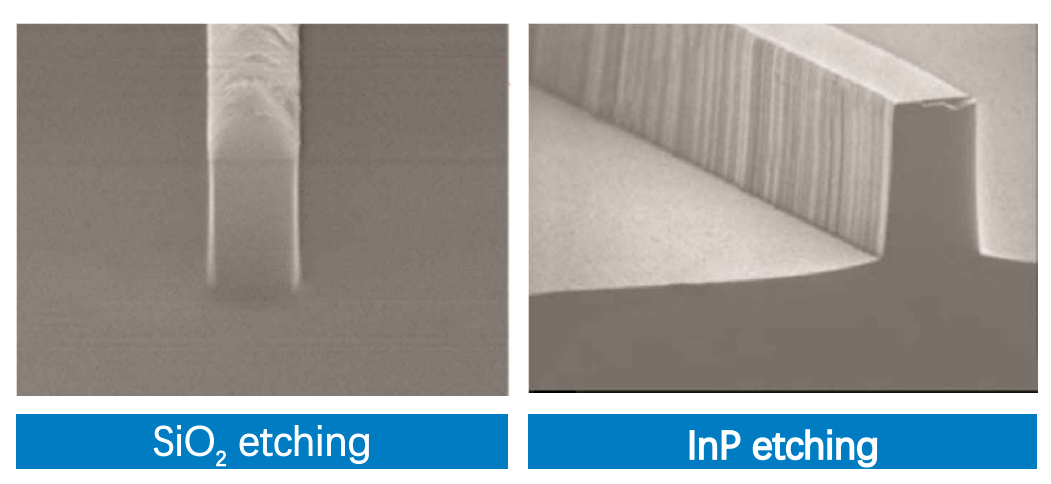

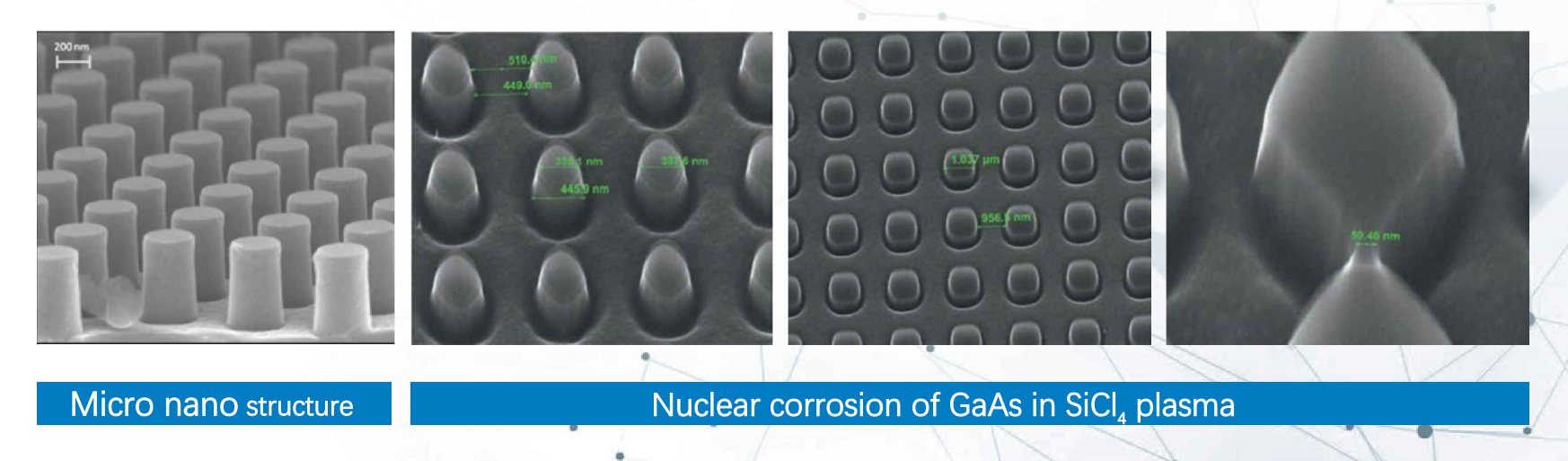

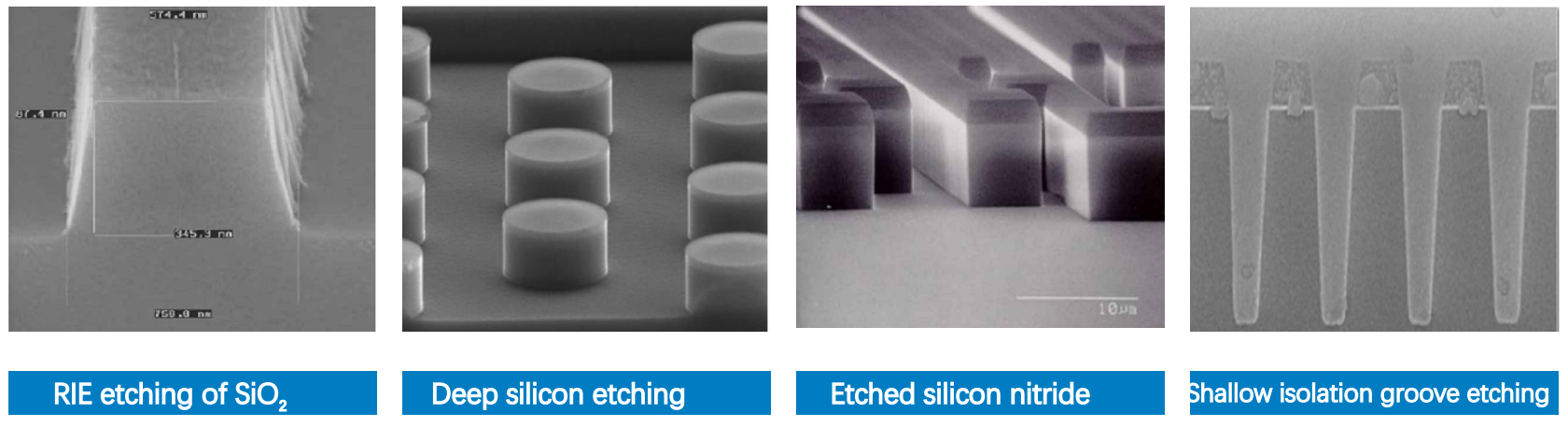

Reactive Ion Etching (RIE)

RIE is a simple and economical plasma etching solution, with common applications such as mask etching and failure analysis.

RIE Features:

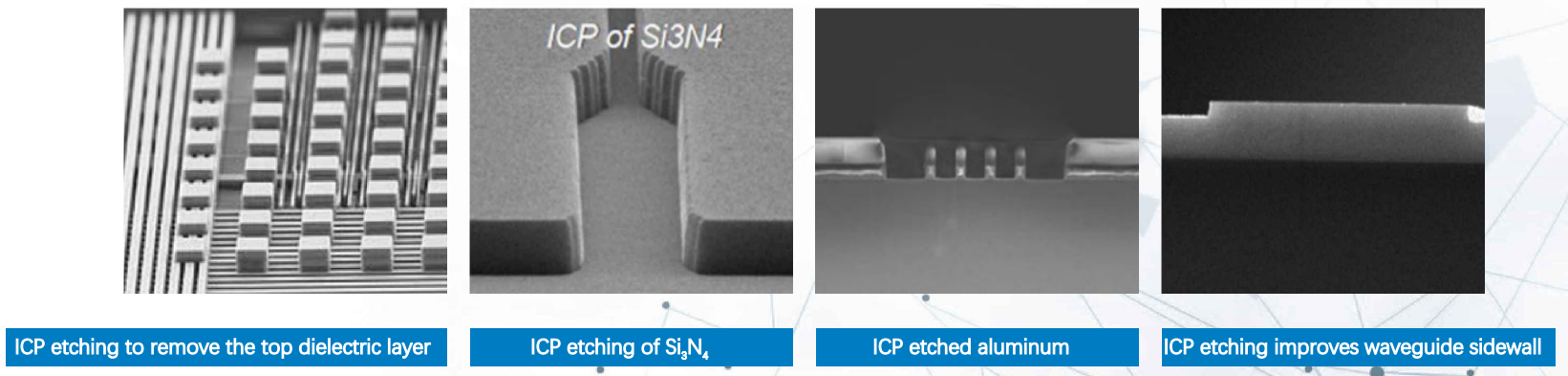

Inductively Coupled Plasma Etching (ICP)

The ICP etching source produces high-density active reactive ions at low pressure.

ICP Etching Features:

Plasma Enhanced Chemical Vapor Deposition (PECVD):

The PECVD process modules are specifically designed to produce thin films with excellent uniformity and high deposition rates, and to modify the material properties of the films, such as refractive index, stress, electrical properties, and wet etch rates.

PECVD features:

The optimized upper electrode, working under high voltage, high RF power and high flow conditions, can accelerate the deposition rate of SiO2, Si3N4, SiON and amorphous Si while ensuring film performance and wafer uniformity.

RF process gas device, with corresponding gas delivery design, provides uniform plasma process through LF/RF switch, thereby accurately controlling film stress.

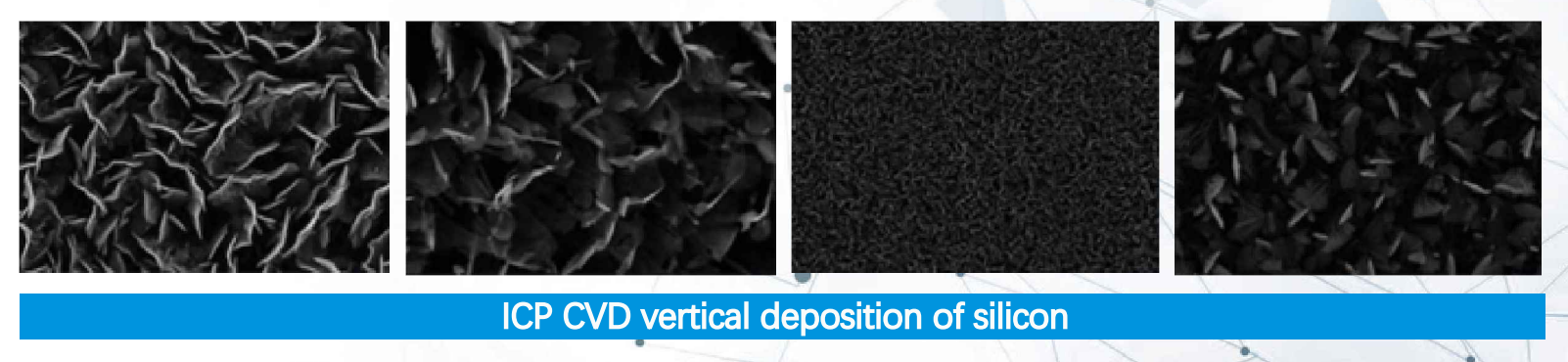

Inductively Coupled Plasma Chemical Vapor Deposition (ICP / CVD)

The ICP/CVD process module is used to deposit high quality thin films using high density plasma at low deposition pressure and temperature.

ICP / CVD features:

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved